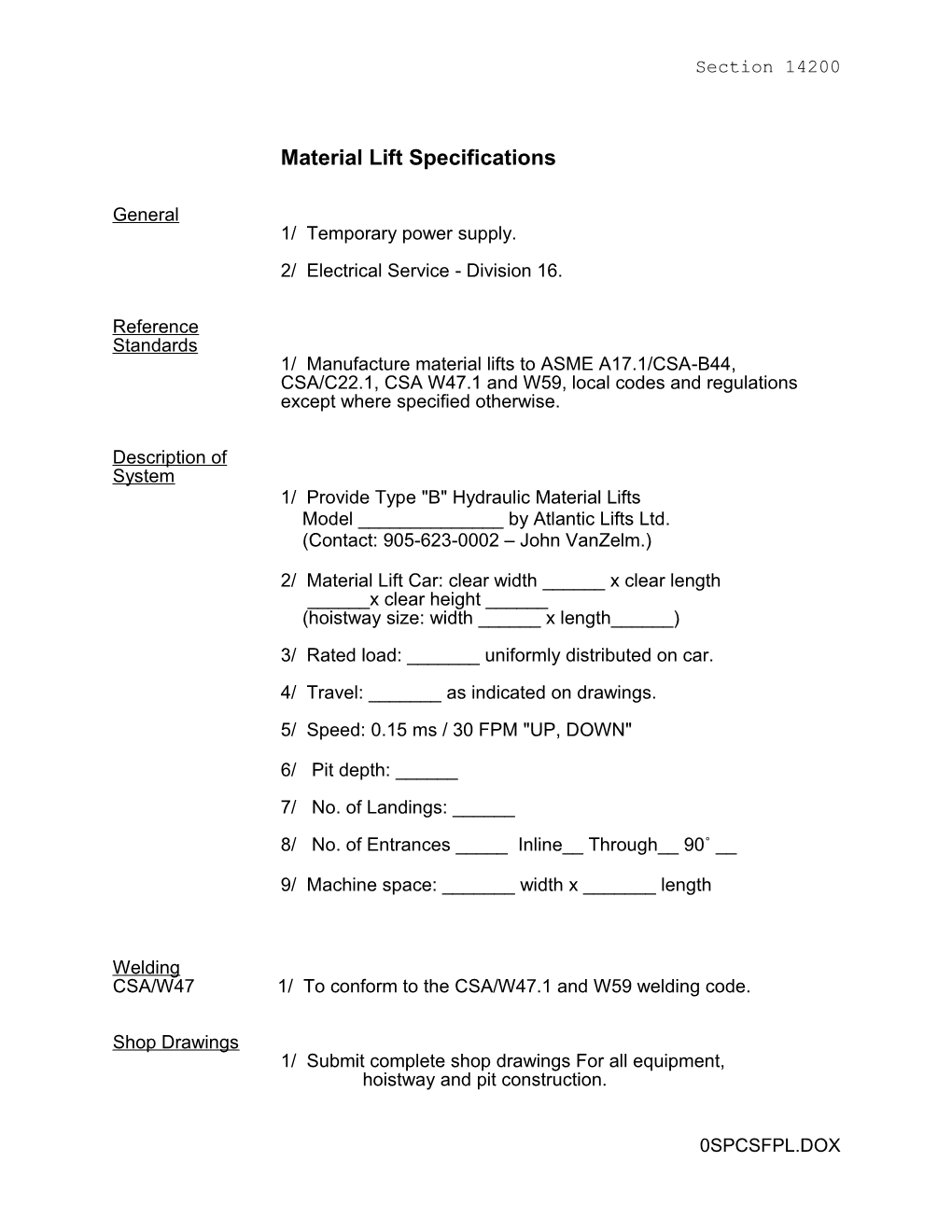

Section 14200

Material Lift Specifications

General 1/ Temporary power supply. 2/ Electrical Service - Division 16.

Reference Standards 1/ Manufacture material lifts to ASME A17.1/CSA-B44, CSA/C22.1, CSA W47.1 and W59, local codes and regulations except where specified otherwise.

Description of System 1/ Provide Type "B" Hydraulic Material Lifts Model ______by Atlantic Lifts Ltd. (Contact: 905-623-0002 – John VanZelm.)

2/ Material Lift Car: clear width ______x clear length ______x clear height ______(hoistway size: width ______x length______)

3/ Rated load: ______uniformly distributed on car. 4/ Travel: ______as indicated on drawings.

5/ Speed: 0.15 ms / 30 FPM "UP, DOWN"

6/ Pit depth: ______7/ No. of Landings: ______8/ No. of Entrances _____ Inline__ Through__ 90˚ __

9/ Machine space: ______width x ______length

Welding CSA/W47 1/ To conform to the CSA/W47.1 and W59 welding code.

Shop Drawings 1/ Submit complete shop drawings For all equipment, hoistway and pit construction.

0SPCSFPL.DOX Section 14200

2/ Location and size of the required fused disconnect.

Maintenance Data 1/ Provide maintenance manuals c/w separate breakdown of the hydraulic cylinder, hydraulic power pack, hydraulic and electrical schematics.

Power Supply Required 1/ Primary Power supply ______Volts. Fused disconnect in machine space. 2/ Separate Lighting supply 120/1/60. GFCI receptacle for Machine Space.

3/ Separate Lighting supply 120/1/60. GFCI receptacle for Pit area. Warranty 1/ Provide two year written parts and labour guarantee.

Cylinder and plunger 1/ Construct plunger of select chromed shafting, machined true to surface finish of 0.0008 mm roughness rating or better.

2/ At top of cylinder provide stuffing box and seal. 3/ Provide safety bulkhead on cylinder to ASME A17.1/CSA-B44.

4/ Install cylinder and plunger plumb. Operate with minimum friction.

Electro - Hydraulic System 1/ Provide hydraulic system consisting essentially of hydraulic pump, holeless side mounted synchronized hydraulic cylinder(s), and piston, pressure relief valve, fluid reservoir, valves, and connections.

2/ Operate pump continuously in "up" direction, "down" travel shall be by gravity.

3/ Include:

0SPCSFPL.DOX Section 14200

1. Internal Stop Ring to prevent piston from leaving cylinder in case of limit switch failure. 2. Oil seals, wipers, guide bearings, gaskets, oil connections, and air elimination means. 3. Pump suction-line strainer. 4. Fluid-level gauge with minimum fluid level clearly indicated. 5. Reservoir with filling opening filter and cover, also with reservoir vent that will not allow entrance of dust. 6. Safety orifice at cylinder(s) to control oil flow in case of pipe breakage.

Control System 1/ Control material lift by heavy duty, constant pressure push-button stations. (CPPB)

2/ Push-buttons to be clearly and permanently identified "UP", "DOWN" and "STOP".

3/ Provide accurately controlled stopping in both up and down directions and maintain car in any position at which it is stopped until direction button is pressed.

4/ Provide approved limit switch to limit up travel of car.

Material Lift Car 1/ Construct car of 1/4” Steel Checker Plate. 2/ Provide 12GA steel panel sides (to match door height.)

Hoistway 1/ As per building code requirements

Finish 1/ Ferrous metal: 1. Clean metal surfaces, treat with phosphate. 2. Apply one coat of primer in accordance with CGSB 1-GP-40M. 3. Apply one coat of alkyd type machine enamel manufacturer’s standard colour.

2/ Fasteners: 1. Zinc or cadmium finish.

0SPCSFPL.DOX Section 14200

Doors And Frame 1/ Double swing clear opening: ______width x ______clear opening height x 1-1/2hr fire rated, or wire mesh as per building code

Custom doors: ______Field Quality Control 1/ Perform and meet tests required by authorities having jurisdiction.

2/ Supply instruments and carry out additional specified tests to approval of Engineer.

3/ Submit to Engineer test and approval certificates issued by jurisdictional authorities.

4/ Test stop ring and hydraulic system by operating car with rated load in up direction against stop ring at rated speed.

0SPCSFPL.DOX