Meeting Minutes

TASK FORCE ON API STD-2000

COMMITTEE ON PRESSURE RELIEVING SYSTEMS

API 2012 Spring Refining and Equipment Standards Meeting

09:00 A.M. – 03:30 P.M. Hyatt Regency at Reunion Wednesday, April 25, 2012 Dallas

Brad Otis, Convenor ISO 28300

Brad Otis, Chairman API STD 2000

Michael Davies, Project Leader ISO 28300

I. Introductions and registration of attendance (All) The meeting started at 9:00 AM. Brad Otis, Convenor ISO 28300 and Chairman API STD 2000, led the meeting. Michael Davies, Project Leader ISO 28300, was present as well as 43 attendees. The attendance and distributions lists were circulated around the room.

II. Appointment of secretary to keep meeting minutes (All) Thomas Heidermann volunteered to keep the minutes.

III. Approval of meeting minutes Fall 2011 ISO-28300/API 2000 Los Angeles Meeting Minutes: The meeting minutes were approved without amendments.

IV. Presentation Michael Davies gave a presentation on the differences between inbreathing calculation of Annex A and the calculation method described in the main body.

We would like to include in Annex C a brief explanation of why the two methods produce significantly different inbreathing results. Action: Michael Davies will prepare a brief paper to answer the inquiry, explain the different assumptions made with the two methods. Aubry Shackelford, Don Eure, Tom Bevilacqua, Clark Shepard and Paolo Pagot will review.

V. Review of inquiries / correspondence on API 2000/ISO 28300 a) Old inquiries

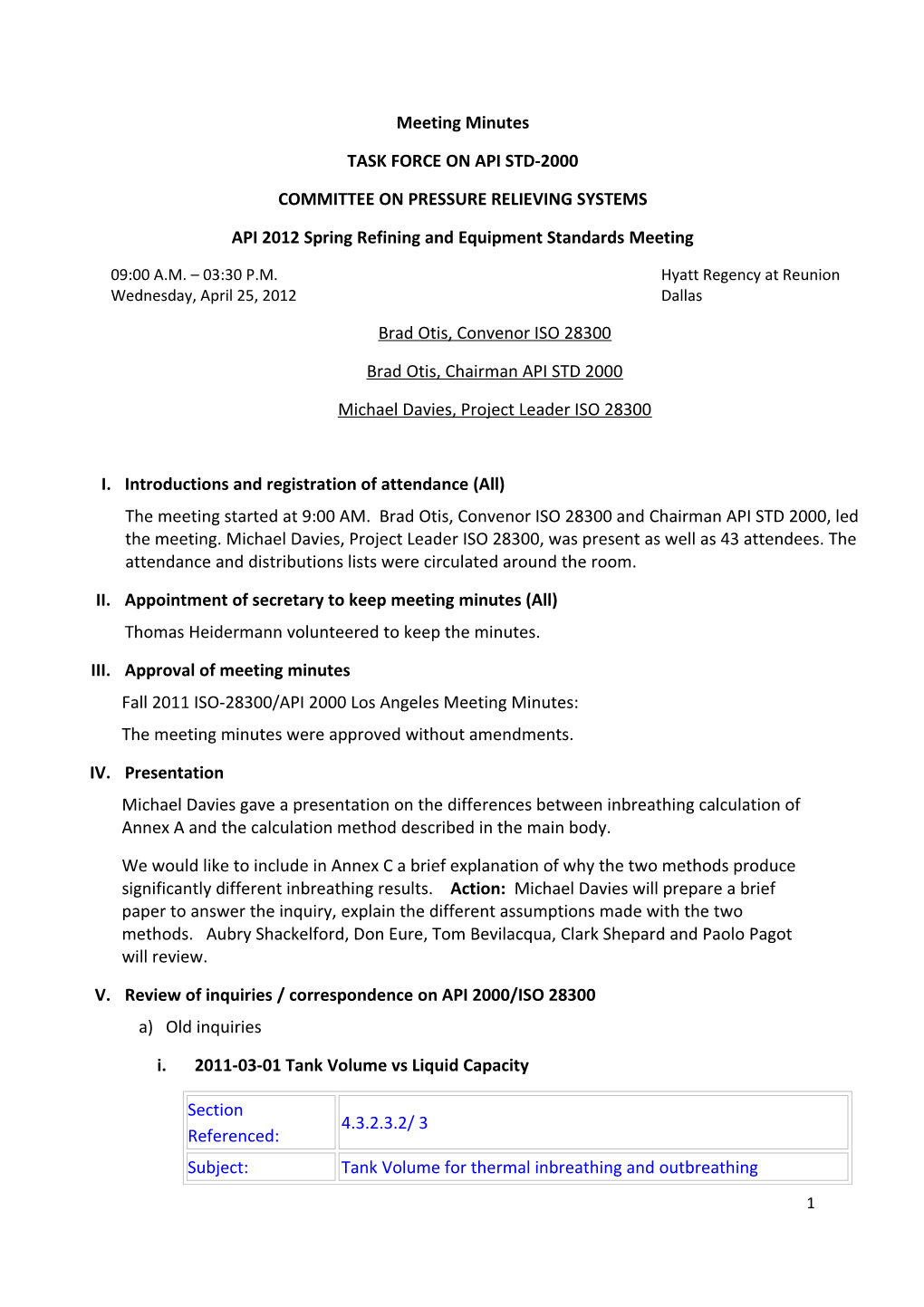

i. 2011-03-01 Tank Volume vs Liquid Capacity

Section 4.3.2.3.2/ 3 Referenced: Subject: Tank Volume for thermal inbreathing and outbreathing

1 Sections 4.3.2.3.2 and 4.3.2.3.3 indicate formulae for thermal inbreathing and outbreathing with tank volume as one of the Background: variable. The tank volume, Vtk, is typically considered as the gross volume of the tank (cylindrical section plus roof section). Similarly tank capacity in Annex A is the gross capacity of tank. Is this interpretation of tank volume/ capacity as gross volume of Question: tank is the intended one? First Name: Unmesh Last Name: Shevade

Response: The models based on the gross volume the total volume, including roof. Using the tank capacity and not the total volume is a simplification of the calculation. This needs to be worked more in the committee.

ii. 2011-09-16 Height for Control Devices

Section Text Referenced: Subject: Tank vents -- ducting Background: See below What is minimum vertical vent height for take offs from vapor Question: vents being ducted to a control device from gasoline/flammable liquid storage tanks? Tom McGowan 404 627 4722 First Name: Tom Last Name: McGowan Email: [email protected] Company: TMTS Associates, Inc. Phone: 404 627 4722

At the Fall 2011 meeting we asked what a control device was. Answer received was: A control device would include:Flare, thermal oxidizer, catalytic oxidizer, recuperative oxidizer, regenerative oxidizer, or regenerative catalytic oxidizer, activated carbon, refrigerated condenser, boiler or fired heater, or less commonly, biobeds

Response: Inquiry is out of scope of the document iii. 2011-09-18 API-2000: Inbreathing Old vs New Standard

2 The API STANDARD 2000 SIXTH EDITION, NOVEMBER 2009 indicates method for calculation of thermal inbreathing by formula.

For a case where volume of tank is 300 m3, located in Muscat (latitude 23 deg) the C factor for hexane fluid is 6.5. Thus the inbreathing requirement for a uninsulated tank works out to be 352 Nm3/hr. However Annexure A which gives an alternative calculation method gives 50.4 Nm3/hr as the inbreathing requirement based on Table A.3. Appreciate if you could clarify this huge apparent discrepancy in the standard. Thanks and regards,

Benoy John Principal Process Engineer Mott MacDonald & Company LLC PO Box 587, PC 112, Ruwi, Sultanate of Oman

Response: Michael Davies will prepare a brief paper to answer the inquiry, explain the different assumptions made with the two methods.

a) New inquiries

i) 2011-11-12 PVV Vacuum Certification

From Hasegawa of FUKUI co., ltd Japan

Thank you for your always effort above captioned ISO28300, And we would like to confirm as following paragraph 6.2.4 Test tank e) For testing vacuum valves, reverse the flow direction, i.e. air is drawn….. Please revise as following into one word better; “reverse/verse” Because ASME code requirements and addressed section 3 2010 Division1-Subsection ND class component ND-7751.3 test method of capacity verification of vacuum relief valves could be used as followings sentence, “capacity tests may be conducted by pressurizing the valve instead of using a vacuum, ...” We highly appreciate your prompt reply and your clarification, even if you are very busy. Thank you again and best regards

Response: PVVs should be tested in the way they are operated. There may be a difference in valve capacity if the flow is pushed through the device vs being pulled through the device.

ii) 2011-11-12 PVV 180,000 bbl limit

3 Section Referenced: A.1.2, A.1.3 and Table A.3 Normal venting requirements for thermal effects, when Subject: tank capacity is greater than 30 000 m^3. In-breathing & out-breathing normal venting requirements (Nm^3/hr of air) as per table A.3 on page 39 of API 2000, 6th edition are based on the boundary Background: conditions and assumptions furnished in clause A.1.2 of page 36 with the volume of the tank less than 30 000m^3 (180 000 bbl). What should be the approach & attitude of a process engineer to carry out safe flow rates of air (Nm^3/hr)when a tank capacity is greater than 30 000 m^3?. Can we use the linear extrapolation method to determine In-breathing (page39,Column 2) & Out- Question: breathing (page 39, Column 3,4) Nm^3/hr of air quantity? We request to API to offer an idea that will help everyone in my department to work from the same vision and will help in making work at a higher level of proficiency. First Name: Rahul Last Name: Deshpande Email: [email protected] Company: P-Mech Consultant Pvt. Ltd. Phone: 0091-22-27814721/23/24 (Exten.47)

Response: The linear extrapolation method to determine In-breathing capacity may not be sufficient conservative. The vent sizing method described in the main body should be used if the boundary conditions in Annex A cannot be met.

VI. Old Work Items a) Status of DIS-28300

The ballot for the API 2000 revision was positive only one negative vote.

The EU and US embargo regulation in the oil and gas industry lead to a compulsory break of the cooperation of ANSI and ISO/TC 67.

b) Review of the comments

The comments were reviewed by five subgroups:

4 A Definition, Application, Scope (blue)

B Hardware (yellow)

C Standard and Normal Venting (green)

D Grandfathering (pink)

E Deflagration and other (brown)

The results of the subgroups were presented by the group representatives.

Action: Brad Otis will check with API legal if having a date for grandfathering is acceptable or not.

VII. New Work Items a) Forward plan

The ISO deadline for the ballot will be in a few months. The comments of all countries will be collected and reviewed at the next fall meeting.

The document will be updated in consideration of the review of the comments.

b) Other

no other business

VIII. Adjourn The meeting was adjourned at 3:30 pm

5