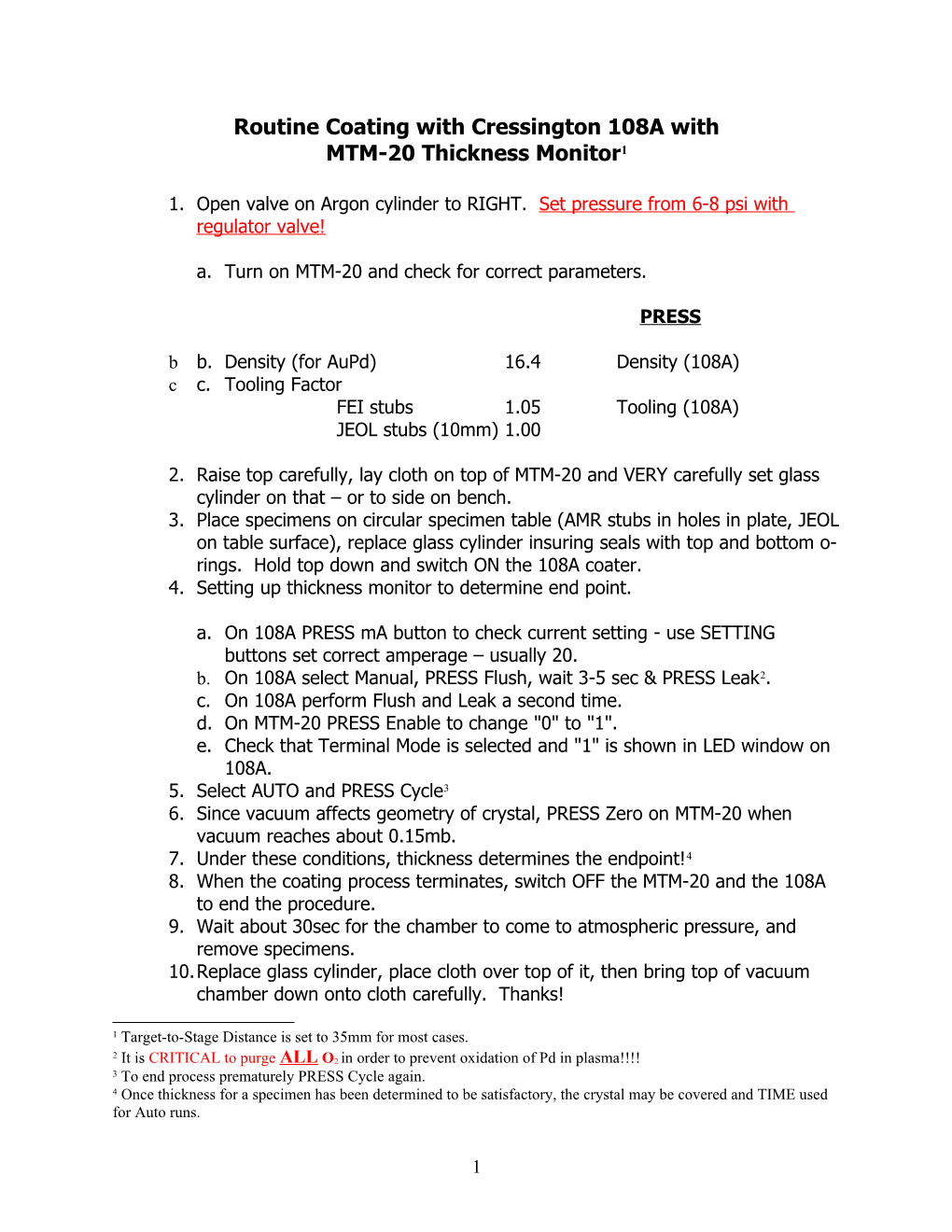

Routine Coating with Cressington 108A with MTM-20 Thickness Monitor1

1. Open valve on Argon cylinder to RIGHT. Set pressure from 6-8 psi with regulator valve!

a. Turn on MTM-20 and check for correct parameters.

PRESS

b b. Density (for AuPd) 16.4 Density (108A) c c. Tooling Factor FEI stubs 1.05 Tooling (108A) JEOL stubs (10mm) 1.00

2. Raise top carefully, lay cloth on top of MTM-20 and VERY carefully set glass cylinder on that – or to side on bench. 3. Place specimens on circular specimen table (AMR stubs in holes in plate, JEOL on table surface), replace glass cylinder insuring seals with top and bottom o- rings. Hold top down and switch ON the 108A coater. 4. Setting up thickness monitor to determine end point.

a. On 108A PRESS mA button to check current setting - use SETTING buttons set correct amperage – usually 20. b. On 108A select Manual, PRESS Flush, wait 3-5 sec & PRESS Leak2. c. On 108A perform Flush and Leak a second time. d. On MTM-20 PRESS Enable to change "0" to "1". e. Check that Terminal Mode is selected and "1" is shown in LED window on 108A. 5. Select AUTO and PRESS Cycle3 6. Since vacuum affects geometry of crystal, PRESS Zero on MTM-20 when vacuum reaches about 0.15mb. 7. Under these conditions, thickness determines the endpoint!4 8. When the coating process terminates, switch OFF the MTM-20 and the 108A to end the procedure. 9. Wait about 30sec for the chamber to come to atmospheric pressure, and remove specimens. 10.Replace glass cylinder, place cloth over top of it, then bring top of vacuum chamber down onto cloth carefully. Thanks!

1 Target-to-Stage Distance is set to 35mm for most cases. 2 It is CRITICAL to purge ALL O2 in order to prevent oxidation of Pd in plasma!!!! 3 To end process prematurely PRESS Cycle again. 4 Once thickness for a specimen has been determined to be satisfactory, the crystal may be covered and TIME used for Auto runs.

1 Normal Sequence when 108A is set to Automatic, and “Cycle” is pressed.

1. pump to 0.05mb 2. open Argon flush for 3sec, then close 3. pump to 0.15mb 4. open argon flush for 3sec, then close 5. open leak valve 6. pump to 0.15mb and continue pumping for another 20sec5 7. switch on sputter supply at preselected current 8. switch off sputter supply after preselected time or thickness setting

Notes on DIFFICULT Samples

1. For elevated samples, differences between top and bottom can be minimized by extending the distance from target to table. Thus the Tooling Factor should get closer to 1.

2. For small specimens use low pressure and low current (0.05mb and 20mA)

5

2