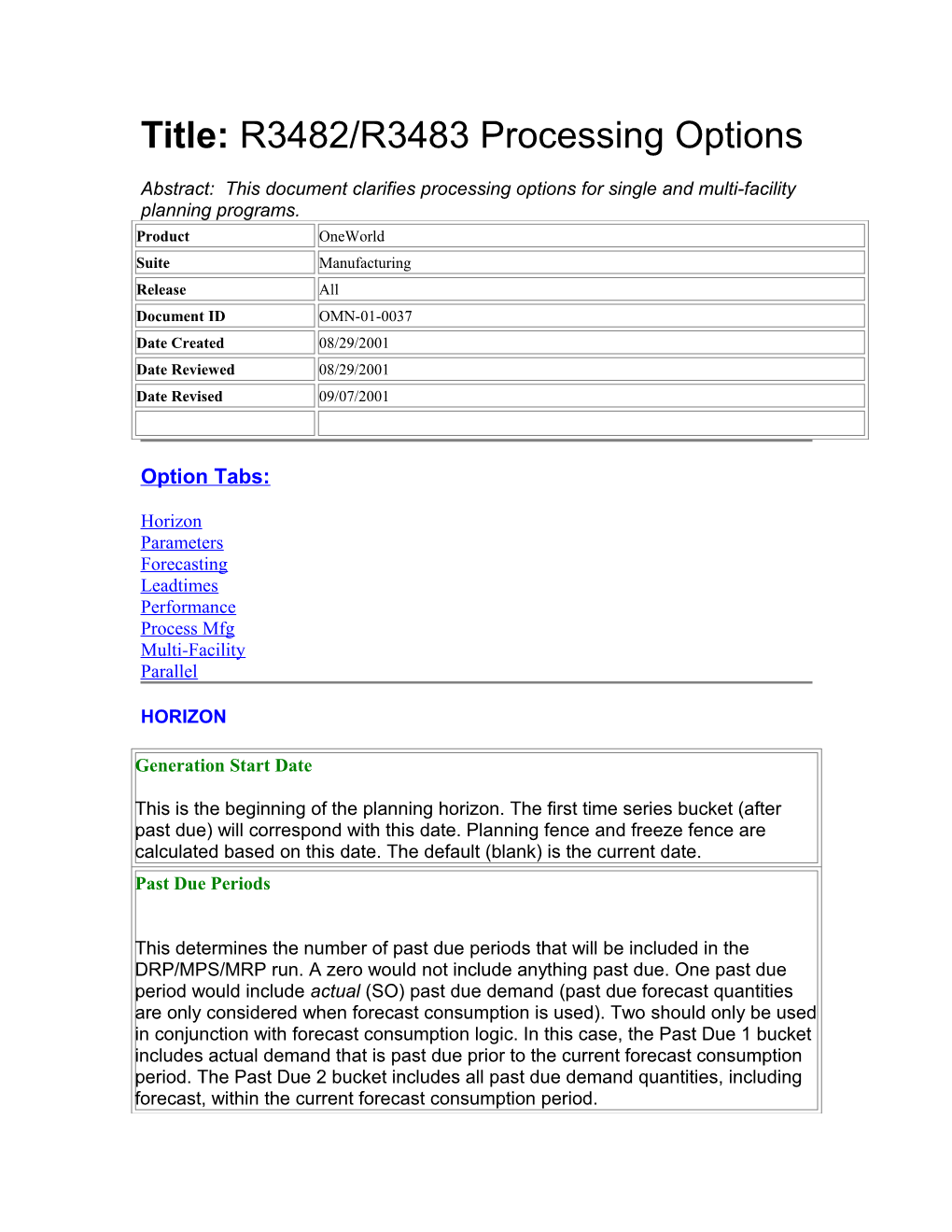

Title: R3482/R3483 Processing Options

Abstract: This document clarifies processing options for single and multi-facility planning programs. Product OneWorld Suite Manufacturing Release All Document ID OMN-01-0037 Date Created 08/29/2001 Date Reviewed 08/29/2001 Date Revised 09/07/2001

Option Tabs:

Horizon Parameters Forecasting Leadtimes Performance Process Mfg Multi-Facility Parallel

HORIZON

Generation Start Date

This is the beginning of the planning horizon. The first time series bucket (after past due) will correspond with this date. Planning fence and freeze fence are calculated based on this date. The default (blank) is the current date. Past Due Periods

This determines the number of past due periods that will be included in the DRP/MPS/MRP run. A zero would not include anything past due. One past due period would include actual (SO) past due demand (past due forecast quantities are only considered when forecast consumption is used). Two should only be used in conjunction with forecast consumption logic. In this case, the Past Due 1 bucket includes actual demand that is past due prior to the current forecast consumption period. The Past Due 2 bucket includes all past due demand quantities, including forecast, within the current forecast consumption period. Planning Horizon Periods

Allows 52 total time periods including past due periods. To allow sufficient planning time for items at the bottom of bills of material, the total planning horizon time span should be at least one and a half times the longest cumulative leadtime of all products. Note that all information is summed up and displayed in total; so, for example, you could have four work orders for 100 each displayed as 400 (+WO) on the time series in a given period. Since the number of periods selected can affect performance, careful consideration should be given about what will meet your needs. For example, if a 1 year planning horizon is needed, 51 weekly buckets with a past due bucket could be specified – but is this really necessary to meet your needs? 8 weeks, and 10 months would provide the same planning horizon without forcing the program to populate 52 buckets. Back to Top Submit Feedback

PARAMETERS

Generation Mode

1 = The Net Change mode is always used in conjunction with ‘Net Change Flag (IBMRPC) = 1’ data selection. Setting this processing option to Net Change (1) is what tells the program to re-plan the components of items that have the net change flag set – otherwise, these items would be excluded by the above data selection. The net change flag in the Item Branch table (F4102) is activated (set to 1) by any transaction that causes a change in supply or demand, and is reset (set to blank) every time the R3482 or R3483 program is run. See pages 5-14 and 5-15 of the Manufacturing and Distribution Planning manual for a list of programs/activities that automatically activate the net change flag. It can also be set or reset via the Net Change Review (P3402). The purpose of running the Net Change mode is to reduce processing time by just re-planning items that have had supply and/or demand changes. However, this is dependant upon the number of changes that have occurred. There will be a threshold number of changes where a Net Change run will actually take longer than a Gross Regeneration. In this mode, the processing option on the performance tab to clear the files (see below) is disabled - the files will not be cleared.

2 = Gross Regeneration will plan everything that is included in the data selection according to the generation type selected (see below). The same is true for the net change mode – the only difference is that in net change mode, the program re- plans the components of parent items that have the net change flag set in spite of being excluded from the data selection (see above). Generation Type

1 = Single Level MRP/DRP - This generation type creates no pegging records. It would be used for two reasons: 1) By a distribution company or a distribution branch of a manufacturing company where no product is manufactured but rather purchased and sold to customers - there are no parent-component relationships (DRP). 2) A manufacturing company that wants to firm up their master production schedule, and then run a gen type 5 to plan material requirements based just on firm work order demand. I.e. this generation type is run data selecting on just master scheduled items (planning code 1), then planners ‘stabilize’ their schedules before planning demand for the components by running a gen type 5 (see below).

2 = Planning Bill (R3482 only) - This generation type is used to take a forecast for a product family – such as a family of bicycles – and distribute the forecast from the family part number to the individual type of bicycle – i.e. it will ‘explode’ a parent forecast to it’s components by multiplying the parents forecast by the feature planning percentage in the bill of material and creating forecasts for the components. For example, if the family had a total forecast of 1000, the program could create forecasts for 100 mountain bikes, 500 racing bikes, and 400 street bikes (with feature planned percentages set to 10%, 50%, and 40% respectively). There are four steps to using this generation type: 1) The parent must have a planning code of ‘4’, which designates it as a ‘Parent in a Planning Bill’. 2) The components must have a planning code of ‘5’, which designates them as ‘Components in a Planning Bill’. 3) The feature planning percent in the bills of material must be set to the proper percentages. 4) You must specify the parent’s forecast type to read and the forecast type to produce for the components (see below). Click here for more detailed information on the use of planning bills.

3 = Multi Level MPS Items - This generation type will do a complete ‘top to bottom’ processing of all data selected items. Demand will be ‘exploded’ down to components from parent items and pegging records will be created. All items that are to be processed must be in the data selection. You cannot just enter the parent items.

4 = MRP with/without MPS - This generation type has exactly the same functionality as generation type 3. SAR number 4494191 has been submitted to eliminate one of them and change the description to just ‘MRP’.

5 = MRP with Frozen MPS - This generation type is used to ‘freeze’ the master schedule once it has been stabilized. A basic assumption is that work orders have been created from messages to cover the master schedule demand. This generation type will freeze the entire planning horizon - similar in concept to the freeze fence, which freezes just a part of the horizon. No new work orders will be planned. No messages for existing work orders will be created. The adjusted ending available is allowed to go negative. Demand is only ‘exploded’ down to components from existing work orders. There is no ‘-PWO’ demand from parent items, only ‘-FWO’ demand. All of this logic is hard coded for Planning Code ‘1’ only (master schedule items). I.e. the use of this gen type is dependent upon proper set up of the planning codes - planning code 1 items will not be re-planned.

UDC Type Enter the User Defined Code Type that contains the list of quantity types to be calculated & written to the time series file (F3413). UDC 34/QT contains a master list of quantity types that can be written and will be used as the default. Generally, this should not be changed – the QT table should be used. Any alternate quantity tables that are created must be based on the QT table because the numeric codes will always specify the same quantity type. For example, 20 will always be +PO, regardless of how the first and second descriptions on the table are modified. Version of Supply/Demand Inclusion Rules

The version specified determines what the program includes as supply and demand. To view/edit the rules, go to G3442/16. It is the next status that is used for sales orders and purchase orders. Work orders don’t have order activity rules and therefore no last/next status – you just select work order statuses to be included as supply. In order to view/edit work order document types other than WO, the doc type(s) will need to be specified in the processing option behind S/D Inclusion Rules (P34004). Back to Top Submit Feedback

FORECASTING

Forecast Types Used (up to 5)

Enter up to five forecast types with no separating characters between. This determines what forecasts will be included as demand. MPS Forecast Type For Planning Bills

If you are generating forecasts from a planning bill (see generation type 2 above), this is where you specify the forecast type to be created. Forecast Consumption Logic

As stated, a ‘1’ will turn on forecast consumption logic. However, there is other set-up required to use forecast consumption. Click here for more information on the set up and use of forecast consumption logic. Interplant Demand Consumes Forecast

This multi-facility (R3483) processing option determines whether interplant demand will consume the forecast when using forecast consumption logic. Click here for more information on the set up and use of forecast consumption logic. Back to Top Submit Feedback

LEADTIMES Expedite Damper Days

If the number of days between when an order is actually needed and the due date of the order is less than the number of days entered here, there will be no expedite message. Example: due date = 01/15, need date = 01/10, damper days = 6 – no expedite message. This reduces system ‘nervousness’. Defer Damper Days

Same as above for defer messages. It is more likely that defer messages will be filtered out than expedite messages since most users will want to be aware of every expedite situation. Back to Top Submit Feedback

PERFORMANCE

Clear F3411/3412/3413 Tables

If this option is left blank, information from previous runs will remain in the files specified if those items are not included in the data selection. If set to ‘1’, this option clears the specified files for all items in every branch whether or not they were included in the data selection. When running in net change mode this processing option is disabled - the files will not be cleared. Initialize MPS/MRP Print Code

When this processing option is set to 1, the MRPD field in the Item Branch File (F4102) is populated by the program with a 1 for items that were included in the data selection that do not have outstanding messages. It is populated with a 2 for items with outstanding messages. Items that were not included in this generation will have MRPD blank. This can then be used in data selection for the Plan & Message Detail Report (R3450). Turning this on just establishes a convenient way to data select if you choose to print MRP outputs. It is not required that you turn this on just because you would like to print this report. Messages And Time Series For Phantoms

While you will never generate a work order for a phantom item, this processing option allows you to generate messages and times series records for reference purposes. Ending Work Order Status

When a work order status is specified here, messages will still be received for parent items (with FPO in the Planner Remarks). However, the component demand planning will continue to be based on the unadjusted condition of work orders with a status greater than or equal to the status specified - i.e. no corresponding messages will be received for the components. Instead, FPO Adjustment Suggestion message(s) will be received. For example, with no actual or forecast demand to justify an existing work order at the status specified here, a cancel message would be received for the parent (with 'Cancel FPO' in the planner remarks). Corresponding messages to cancel or decrease existing orders for the components required for this work order would not be received. FPO Adjustment Suggestion message(s) that refer to the work order number with 'Cancel Parts List' in the planner remarks would be received instead. Extend Rate Based Adjustments

This must be populated with a one for the program to plan for rate schedule components. Back to Top Submit Feedback

PROCESS MFG

Process Planning

If you are not using process manufacturing, leave this blank. This option could have been included under the performance tab - if left blank, the run time of the generation will be reduced. Back to Top Submit Feedback

MULTI-FACILITY

Process Each Branch

It appears (based on extensive testing and input from our development group) that this multi-facility (R3483) processing option is just carry-over from an earlier version, is no longer useful, and will be removed in a future release. Just leave this option blank. Date Branch

This is a multi-facility (R3483) processing option. When a branch is specified here, only the shop floor (work day) calendar for this branch will be used by the program for date processing. If left blank, the calendar for each branch being processed will be used, thereby increasing processing time, and making it necessary to maintain multiple calendars. Consolidation Method

This multi-facility (R3483) processing option determines how the multi-plant demand will be handled. A 1 tells the program to do a simple consolidation, which will not use branch plant relationships. This method provides an aggregate picture of supply and demand across multiple branches – the supply and demand for each branch is added and results are placed in the branch specified in the Consolidation Branch processing option. When 2 is selected to use the branch relationships, there are two additional options that can be used for the MRP generation: Category Code specifies the item branch ‘purchasing’ category codes that the program will use to establish branch plant relationships. When Manufacture At Origin is set to 1, demand for manufactured items will not create transfer messages, regardless of whether branch relationships are set up for the item or there is available inventory in other branches. Instead, WO messages will be generated to satisfy demand. Run Regular Planning

Ignore this option. It does not work and will be removed in a future release. Run the R3482 program instead. Back to Top Submit Feedback

PARALLEL

Number of Subsystem Jobs

If the program is executed on a server that has more than one processor, items can be planned in parallel utilizing multiple processors. This achieves significant performance gains limited only by the number of processors available on your server. To use parallel processing, a separate subsystem version is created. This processing option is used to indicate the number of processors that have been configured for executing the subsystem version. See Understanding Parallel Processing in the Manufacturing & Distribution Planning manual for details. Pre Processing

When using parallel processing with pre-processing turned on, the program checks all tables that define supply and demand (F4211, F4311, F3460, F3111, F4801, F3412, F41021) and determines what items need to be planned. The F986113 table is populated with records to be processed.