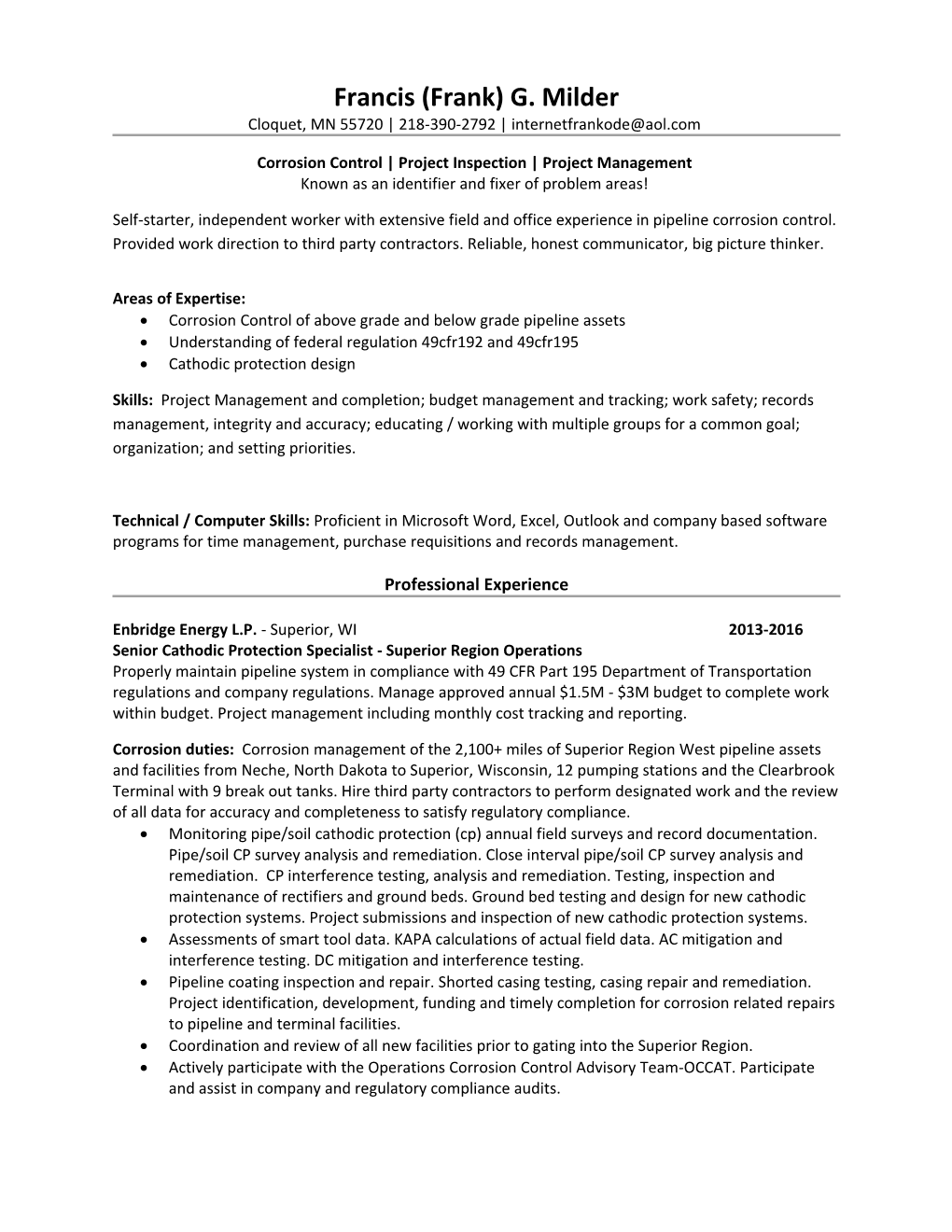

Francis (Frank) G. Milder Cloquet, MN 55720 | 218-390-2792 | [email protected]

Corrosion Control | Project Inspection | Project Management Known as an identifier and fixer of problem areas!

Self-starter, independent worker with extensive field and office experience in pipeline corrosion control. Provided work direction to third party contractors. Reliable, honest communicator, big picture thinker.

Areas of Expertise: Corrosion Control of above grade and below grade pipeline assets Understanding of federal regulation 49cfr192 and 49cfr195 Cathodic protection design

Skills: Project Management and completion; budget management and tracking; work safety; records management, integrity and accuracy; educating / working with multiple groups for a common goal; organization; and setting priorities.

Technical / Computer Skills: Proficient in Microsoft Word, Excel, Outlook and company based software programs for time management, purchase requisitions and records management.

Professional Experience

Enbridge Energy L.P. - Superior, WI 2013-2016 Senior Cathodic Protection Specialist - Superior Region Operations Properly maintain pipeline system in compliance with 49 CFR Part 195 Department of Transportation regulations and company regulations. Manage approved annual $1.5M - $3M budget to complete work within budget. Project management including monthly cost tracking and reporting.

Corrosion duties: Corrosion management of the 2,100+ miles of Superior Region West pipeline assets and facilities from Neche, North Dakota to Superior, Wisconsin, 12 pumping stations and the Clearbrook Terminal with 9 break out tanks. Hire third party contractors to perform designated work and the review of all data for accuracy and completeness to satisfy regulatory compliance. Monitoring pipe/soil cathodic protection (cp) annual field surveys and record documentation. Pipe/soil CP survey analysis and remediation. Close interval pipe/soil CP survey analysis and remediation. CP interference testing, analysis and remediation. Testing, inspection and maintenance of rectifiers and ground beds. Ground bed testing and design for new cathodic protection systems. Project submissions and inspection of new cathodic protection systems. Assessments of smart tool data. KAPA calculations of actual field data. AC mitigation and interference testing. DC mitigation and interference testing. Pipeline coating inspection and repair. Shorted casing testing, casing repair and remediation. Project identification, development, funding and timely completion for corrosion related repairs to pipeline and terminal facilities. Coordination and review of all new facilities prior to gating into the Superior Region. Actively participate with the Operations Corrosion Control Advisory Team-OCCAT. Participate and assist in company and regulatory compliance audits. Francis (Frank) G. Milder| 218-878-9641/218-390-2792| [email protected] | PAGE 2

Northern Natural Gas Company - Carlton, MN 2009–2013 Corrosion Technician, 2009-2013 Maintain pipeline system in compliance with 49 CFR Part 192 Department of Transportation regulations. Corrosion management of pipeline and facilities located in Northern Minnesota and Wisconsin, town border gate stations, Carlton Compressor Station and the Wrenshall Liquified Natural Gas Plant. Design of cathodic protection systems. Testing, inspection and maintenance of rectifiers and ground beds. Pipe/soil cathodic protection (cp) annual field survey and record documentation. Pipe/soil cp survey analysis and remediation. CP interference testing, analysis and remediation. Smart tool data analysis to identify integrity issues. Smart tool data verification inspections. Field assessments of smart tool data. KAPA calculations of actual field data. AC and DC power interference testing. Pipeline coating inspection and repair. Ground bed testing and design for new cathodic protection systems. Project submissions for new cathodic protection systems. Project inspection of new cathodic protection systems. Testing of new ground beds and rectifiers systems. Pipeline current mapper field surveys. Shorted casing testing. Shorted casing repair and remediation. Population density house count surveys and documentation. Gas leakage detection surveys. Pipeline ground and aerial patrols.

Point person for the Carlton Pipeline Operations team. Coordinate pipeline construction and maintenance projects between corporate engineering / construction and third party contractors. Hands on inspection of pipeline facilities for integrity inspections in Minnesota and Wisconsin, NDT inspections and determination of repairs between field engineers / inspectors and corporate pipeline safety. Hands on inspection of smart tool field data in high consequence areas. Line location and marking of pipeline facilities. Maintain pipeline alignment maps for Gopher State One call database. Maintain pipeline records for compliance with DOT regulations. Assist with records and facility inspections with compliance agencies, MNOPS/PHMSA.

Manage damage prevention and public awareness program by performing face-to-face contact meetings between Northern Natural Gas Company, Carlton Pipeline Operations team and emergency responders, public officials, landowners and contractors.

Public Awareness Liaison, 2002-2008 Developed and managed the public awareness program face-to-face contact for Region Operations in Minnesota, Wisconsin, Michigan, South Dakota and Iowa.

Prior Experience: Stumbo Surveying and Bowen Engineering and Surveying

Education / Professional Certifications

B.S. Degree in Civil Engineering, Iowa State University - Ames, IA

Professional Certifications: National Association of Corrosion Engineers / N.A.C.E. Certification Cathodic Protection/Corrosion Technician, Certification # 6456, Membership #142532