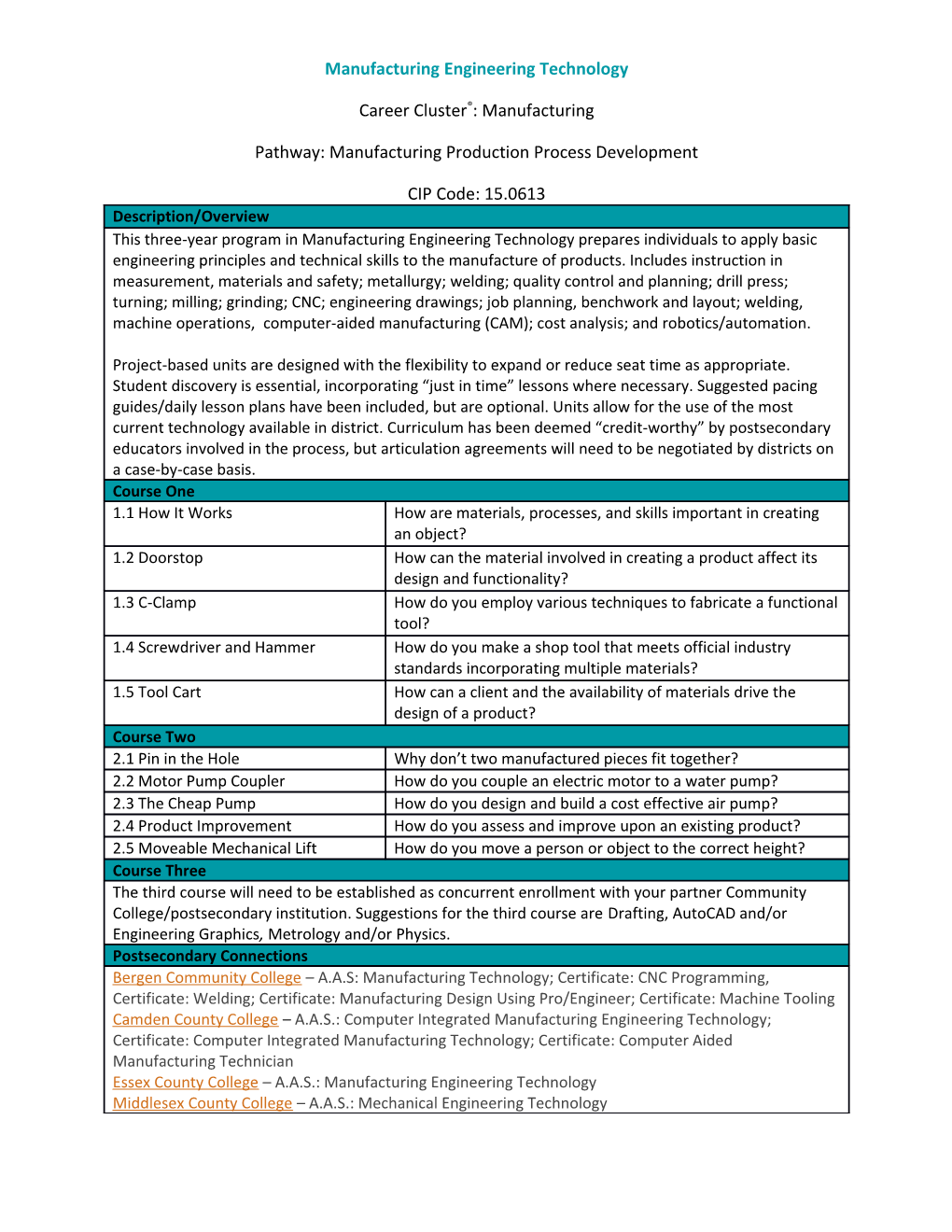

Manufacturing Engineering Technology

Career Cluster®: Manufacturing

Pathway: Manufacturing Production Process Development

CIP Code: 15.0613 Description/Overview This three-year program in Manufacturing Engineering Technology prepares individuals to apply basic engineering principles and technical skills to the manufacture of products. Includes instruction in measurement, materials and safety; metallurgy; welding; quality control and planning; drill press; turning; milling; grinding; CNC; engineering drawings; job planning, benchwork and layout; welding, machine operations, computer-aided manufacturing (CAM); cost analysis; and robotics/automation.

Project-based units are designed with the flexibility to expand or reduce seat time as appropriate. Student discovery is essential, incorporating “just in time” lessons where necessary. Suggested pacing guides/daily lesson plans have been included, but are optional. Units allow for the use of the most current technology available in district. Curriculum has been deemed “credit-worthy” by postsecondary educators involved in the process, but articulation agreements will need to be negotiated by districts on a case-by-case basis. Course One 1.1 How It Works How are materials, processes, and skills important in creating an object? 1.2 Doorstop How can the material involved in creating a product affect its design and functionality? 1.3 C-Clamp How do you employ various techniques to fabricate a functional tool? 1.4 Screwdriver and Hammer How do you make a shop tool that meets official industry standards incorporating multiple materials? 1.5 Tool Cart How can a client and the availability of materials drive the design of a product? Course Two 2.1 Pin in the Hole Why don’t two manufactured pieces fit together? 2.2 Motor Pump Coupler How do you couple an electric motor to a water pump? 2.3 The Cheap Pump How do you design and build a cost effective air pump? 2.4 Product Improvement How do you assess and improve upon an existing product? 2.5 Moveable Mechanical Lift How do you move a person or object to the correct height? Course Three The third course will need to be established as concurrent enrollment with your partner Community College/postsecondary institution. Suggestions for the third course are Drafting, AutoCAD and/or Engineering Graphics, Metrology and/or Physics. Postsecondary Connections Bergen Community College – A.A.S: Manufacturing Technology; Certificate: CNC Programming, Certificate: Welding; Certificate: Manufacturing Design Using Pro/Engineer; Certificate: Machine Tooling Camden County College – A.A.S.: Computer Integrated Manufacturing Engineering Technology; Certificate: Computer Integrated Manufacturing Technology; Certificate: Computer Aided Manufacturing Technician Essex County College – A.A.S.: Manufacturing Engineering Technology Middlesex County College – A.A.S.: Mechanical Engineering Technology Manufacturing Engineering Technology

Career Cluster®: Manufacturing

Pathway: Manufacturing Production Process Development

CIP Code: 15.0613 County College of Morris – A.A.S.: Mechanical Engineering Technology; Certificate: Computer-Aided Design New Jersey Institute of Technology – B.S.: Manufacturing Engineering Technology Rutgers University – B.A./B.S.: Industrial and Systems Engineering, Manufacturing Systems Engineering option End-of-Program Assessment NOCTI – Job Ready Assessments – Machine Shop Technology Teacher Certification Required Please contact Kate Pereira (Diffenderfer). Training Prior to implementing and receiving curriculum, schools are required to attend training provided by the NJDOE.

Contact Information Kate Pereira (Diffenderfer) 609-984-1331 [email protected]