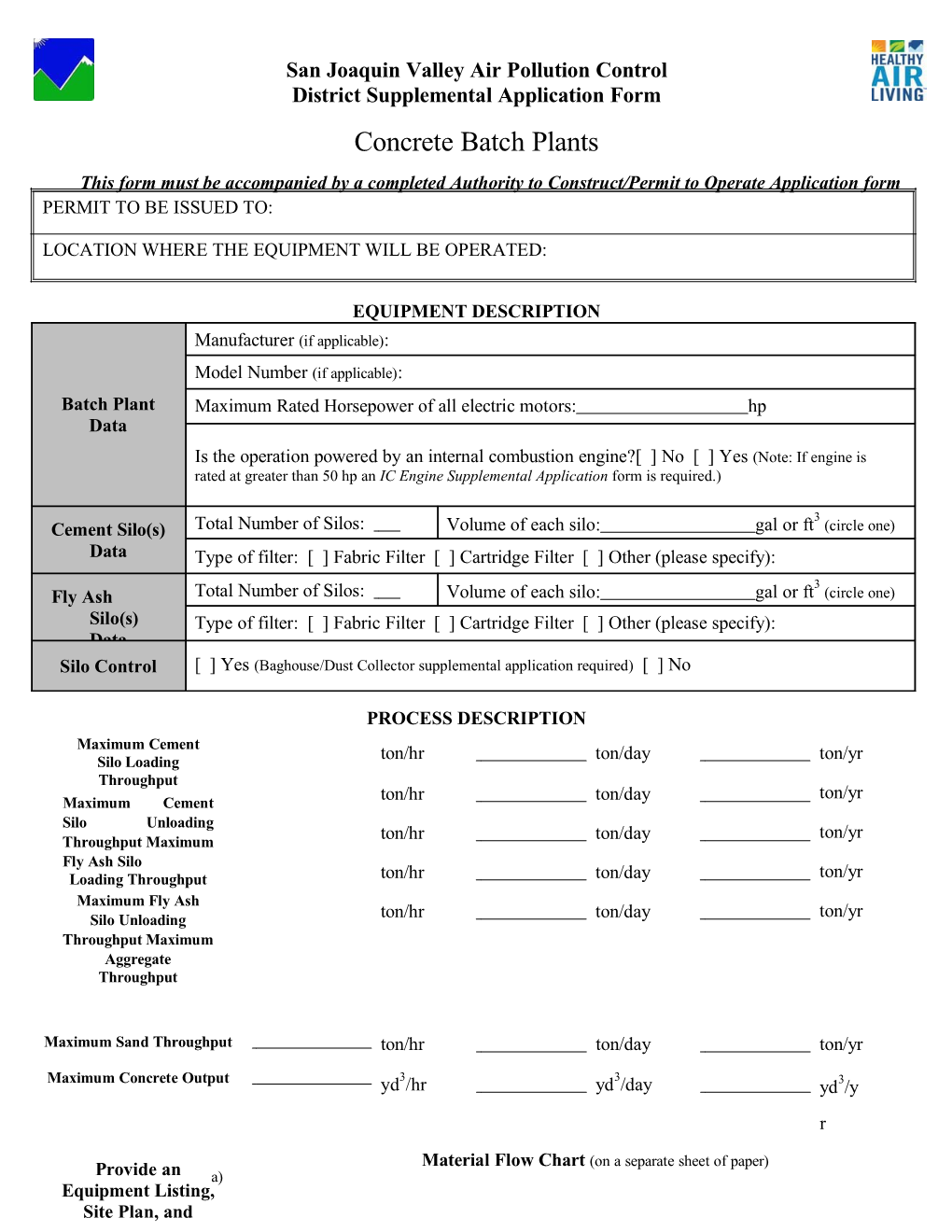

San Joaquin Valley Air Pollution Control District Supplemental Application Form Concrete Batch Plants This form must be accompanied by a completed Authority to Construct/Permit to Operate Application form PERMIT TO BE ISSUED TO:

LOCATION WHERE THE EQUIPMENT WILL BE OPERATED:

EQUIPMENT DESCRIPTION Manufacturer (if applicable): Model Number (if applicable): Batch Plant Maximum Rated Horsepower of all electric motors: hp Data Is the operation powered by an internal combustion engine?[ ] No [ ] Yes (Note: If engine is rated at greater than 50 hp an IC Engine Supplemental Application form is required.)

3 Cement Silo(s) Total Number of Silos: Volume of each silo: gal or ft (circle one) Data Type of filter: [ ] Fabric Filter [ ] Cartridge Filter [ ] Other (please specify): 3 Fly Ash Total Number of Silos: Volume of each silo: gal or ft (circle one) Silo(s) Type of filter: [ ] Fabric Filter [ ] Cartridge Filter [ ] Other (please specify): Data Silo Control [ ] Yes (Baghouse/Dust Collector supplemental application required) [ ] No

PROCESS DESCRIPTION Maximum Cement Silo Loading ton/hr ton/day ton/yr Throughput ton/yr Maximum Cement ton/hr ton/day Silo Unloading ton/yr Throughput Maximum ton/hr ton/day Fly Ash Silo Loading Throughput ton/hr ton/day ton/yr Maximum Fly Ash Silo Unloading ton/hr ton/day ton/yr Throughput Maximum Aggregate Throughput

Maximum Sand Throughput ton/hr ton/day ton/yr

3 3 Maximum Concrete Output yd /hr yd /day yd3/y r

Material Flow Chart (on a separate sheet of paper) Provide an a) Equipment Listing, Site Plan, and b) Provide an equipment listing to for a maximum throughput scenario (include all process, control, and transfer equipment). include the manufacturer and d) Provide a Material Flow Chart for a maximum throughput scenario. (Include all process, control, and transfer model number of all major components. equipment, their types, and their maximum ratings. Also include transfer points, stockpiles, and c) Provide a typical Site Plan air pollution control methods.

Northern Regional Office * 4800 Enterprise Way * Modesto, California 95356-8718 * (209) 557-6400 * FAX (209) 557-6475 Central Regional Office * 1990 East Gettysburg Avenue * Fresno, California 93726-0244 * (559) 230-5900 * FAX (559) 230-6061 Southern Regional Office * 34946 Flyover Court * Bakersfield, California 93308 * (661) 392-5500 * FAX (661) 392-5585 Revised: January 2009 PROCESS DESCRIPTION (Continued) Is this a “Wet Mix” Is this a “Transient [ ] Yes [ ] No [ ] Yes [ ] No type plant? Mix” dry type plant? Mechanical Cement Transfer Quantity of transfer points controlled by: Number of Points: Points [ ] Fabric Filter [ ] Bin Vent Filter [ ] Other (please specify) [ ] None Pneumatic Cement Transfer Quantity of transfer points controlled by: Number of Points: Points [ ] Fabric Filter [ ] Bin Vent Filter [ ] Other (please specify) [ ] None Cement Weigh Hopper Quantity of transfer points controlled by: Number of Points: Transfer Points [ ] Fabric Filter [ ] Bin Vent Filter [ ] Other (please specify) [ ] None Mechanical Fly Ash Transfer Quantity of transfer points controlled by: Number of Points: Points [ ] Fabric Filter [ ] Bin Vent Filter [ ] Other (please specify) [ ] None Pneumatic Fly Ash Transfer Quantity of transfer points controlled by: Number of Points: Points [ ] Fabric Filter [ ] Bin Vent Filter [ ] Other (please specify) [ ] None Fly Ash Weigh Hopper Quantity of transfer points controlled by: Number of Points: Transfer Points [ ] Fabric Filter [ ] Bin Vent Filter [ ] Other (please specify) [ ] None Mechanical Aggregate Quantity of transfer points controlled by: Number of Points: Transfer Points [ ] Fabric Filter [ ] Bin Vent Filter [ ] Water Spray [ ] Other [ ] None Mechanical Sand Transfer Quantity of transfer points controlled by: Number of Points: Points [ ] Fabric Filter [ ] Bin Vent Filter [ ] Other (please specify) [ ] None Sand and Aggregate Weigh Quantity of transfer points controlled by: Number of Points: Hopper Transfer Points [ ] Fabric Filter [ ] Bin Vent Filter [ ] Water Spray [ ] Other [ ] None Concrete Transfer Points Quantity of transfer points controlled by: Number of Points: (Truck Loading) [ ] Fabric Filter [ ] Bin Vent Filter [ ] Water Spray [ ] Shroud [ ] None

PLANT LAYOUT DESCRIPTION

Total Area of Unpaved 2 Type of control: [ ] Water [ ] Oil/Dust Area: acre or ft (circle one) Roads within the Palliate [ ] Other (please specify):

TotaPlantl Area of Aggregate 2 Type of control: [ ] Water [ ] Physical Covering Area: acre or ft (circle one) Piles within the Plant [ ] Retaining Walls [ ] Other (please specify):

HEALTH RISK ASSESSMENT DATA Operating Hours Maximum Operating Schedule: hours per day, and hours per year Distance to Distance is measured from the proposed stack location to the feet nearest Residence nearest boundary of the nearest apartment, house, dormitory, Direction to nearest etc. Direction from the stack to the receptor, i.e. North or South. Residence Receptor Data Distance to nearest Distance is measured from the proposed stack location to the feet Business nearest boundary of the nearest office building, factory, store, etc. Direction to nearest Direction from the stack to the receptor, i.e. North or South. Business Release Height feet above grade Stack Stack Diameter inches at point of release Parameters Rain Cap [ ] Flapper-type [ ] Fixed-type [ ] None [ ] Other: Direction of Flow [ ] Vertically Upward [ ] Horizontal [ ] Other: from vert. or from horiz. Exhaust Data Flowrate: acfm Temperature: F Facility Location [ ] Urban (area of dense population) [ ] Rural (area of sparse population)

Describe any additional air pollution control equipment or technologies, including control efficiencies, on a separate sheet and submit it along with this form. FOR DISTRICT USE ONLY Date: FID: Project: Public Notice: Y N Comments: