Natare® Swimming Pool systems Typical Specification

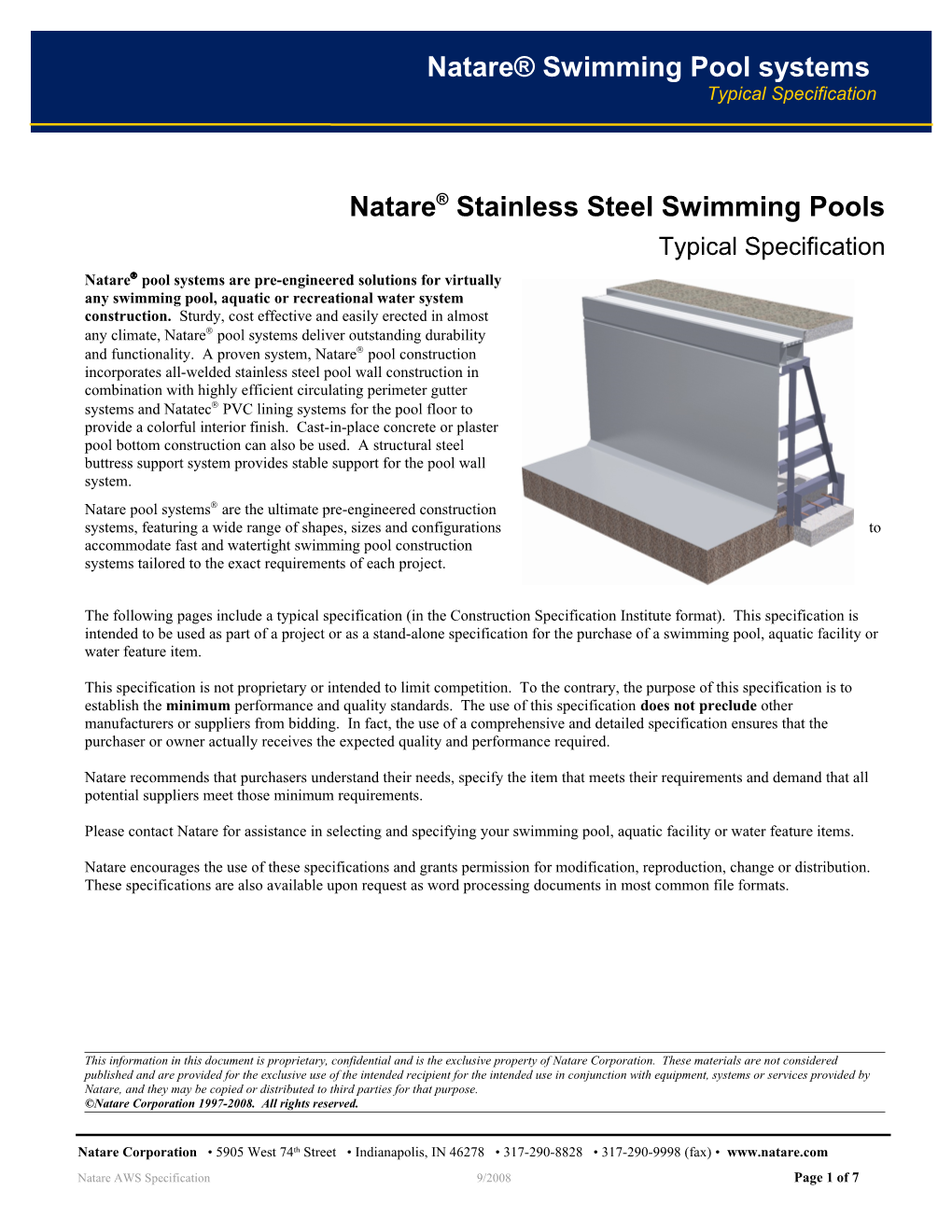

Natare® Stainless Steel Swimming Pools Typical Specification Natare pool systems are pre-engineered solutions for virtually any swimming pool, aquatic or recreational water system construction. Sturdy, cost effective and easily erected in almost any climate, Natare pool systems deliver outstanding durability and functionality. A proven system, Natare pool construction incorporates all-welded stainless steel pool wall construction in combination with highly efficient circulating perimeter gutter systems and Natatec PVC lining systems for the pool floor to provide a colorful interior finish. Cast-in-place concrete or plaster pool bottom construction can also be used. A structural steel buttress support system provides stable support for the pool wall system. Natare pool systems are the ultimate pre-engineered construction systems, featuring a wide range of shapes, sizes and configurations to accommodate fast and watertight swimming pool construction systems tailored to the exact requirements of each project.

The following pages include a typical specification (in the Construction Specification Institute format). This specification is intended to be used as part of a project or as a stand-alone specification for the purchase of a swimming pool, aquatic facility or water feature item.

This specification is not proprietary or intended to limit competition. To the contrary, the purpose of this specification is to establish the minimum performance and quality standards. The use of this specification does not preclude other manufacturers or suppliers from bidding. In fact, the use of a comprehensive and detailed specification ensures that the purchaser or owner actually receives the expected quality and performance required.

Natare recommends that purchasers understand their needs, specify the item that meets their requirements and demand that all potential suppliers meet those minimum requirements.

Please contact Natare for assistance in selecting and specifying your swimming pool, aquatic facility or water feature items.

Natare encourages the use of these specifications and grants permission for modification, reproduction, change or distribution. These specifications are also available upon request as word processing documents in most common file formats.

This information in this document is proprietary, confidential and is the exclusive property of Natare Corporation. These materials are not considered published and are provided for the exclusive use of the intended recipient for the intended use in conjunction with equipment, systems or services provided by Natare, and they may be copied or distributed to third parties for that purpose. ©Natare Corporation 1997-2008. All rights reserved.

Natare Corporation • 5905 West 74th Street • Indianapolis, IN 46278 • 317-290-8828 • 317-290-9998 (fax) • www.natare.com Natare AWS Specification 9/2008 Page 1 of 7 PROJECT NAME Description

SECTION 1315—NATARE STAINLESS STEEL SWIMMING POOL SYSTEM PART 1 - GENERAL

0.1 SUMMARY

The method of swimming pool construction, and designs specified and shown on the detailed drawings, are intended as the basis for receiving bids and is the preference of the Owners. It is not the intent of these Specifications to in any way limit competition or restrict the bidder in the preparation of his bid. It is assumed, however, that unless stated otherwise, that the bidder is offering exactly the equipment, products, quantity of items as specified herein and is totally obligated to furnish that equipment in literal compliance with these Specifications. Substitute system(s) must be approved by the Architect/Engineer a minimum of ten (10) days prior to the bid opening date by submitting a full equipment list of all items he intends to supply, showing pool construction techniques, materials and systems, structural data, engineering calculations and other pertinent data as outlined in the Specification. Said request for substitution should include a detailed explanation of why such substitute is being requested. In the event an alternate system is approved, all contractors will be so advised per addendum prior to bid opening allowing all contractors a fair and equitable opportunity to include such a system or equipment in their bids.

0.2 The System specified shall be a Natareä Stainless Steel Swimming Pool System and is the proprietary product and sole property of Natare Corporation, Indianapolis, Indiana. Other aspects, equipment and construction within the project have been designed to utilize its principles. No alternates will be accepted under this base bid as they could adversely affect the ultimate performance of the system.

0.3 SCOPE OF WORK

The system hereinafter specified consists of and shall include an all stainless steel pre-fabricated side wall system with an integrally formed filtered water supply duct and perimeter overflow channel, as detailed on the drawings. The stainless steel sidewall system shall be joined to a stainless steel pool bottom in the dimensions and slopes indicated on the drawings. The stainless steel floor (bottom) shall include main drain boxes with integral hydrostatic valves and PVC grating. The entire system shall be flush, with no protrusions. The stainless steel wall shall be supported by a bitumastic-coated or galvanized mild steel buttress system and horizontal support members engineered to derive strength and support from a surrounding concrete tank already in place. The stainless steel perimeter recirculation system consists of an overflow gutter with skimming weirs, a supply tube with multiple jet inlets disposed about the perimeter of the pool and stainless steel gutter collector and supply converter boxes at locations indicated on the drawings. The entire swimming pool shall be built as a single unit with all steel and stainless steel components welded together as indicated on the drawings.

A. Included shall be an integral perimeter deck drain, also formed from stainless steel, which shall be continuous around the periphery of the swimming pool.

B. Deck equipment and other pool accessory items as detailed in other project specifications, including all anchors, inserts and sleeves, shall be furnished in the types described and quantities shown on the drawings for installation by the Contractor, as noted.

C. Final drawings and engineering calculations shall be provided to the owner for approval prior to fabrication and on-site installation.

D. Related swimming pool work and responsibilities have been assigned to the various trades or are being assumed by the Owner. The following areas of work which are associated with the swimming pool system are not the responsibility of the swimming pool system's installer and are to be provided by other Contractors or by the Owner in accordance with the specification outlined herein and detailed notations on the drawings.

1. Building-permit fees, licenses and Health Department approvals.

2. Temporary utilities, safety and site requirements. a. Provide temporary water at 50-psi minimum for cleaning, rinsing and test purposes, as well as facilities for draining pool and maintaining workable conditions within the excavated area. b. Provide temporary electrical and lighting as required to the pool site. c. Provide and maintain all necessary barricades, signs, lights, and flares, as required, to protect workmen and the public. d. Provide access to site for pre-fabricated materials and for accomplishing erection of pool. e. Provide adequate protection of finished pool until total project is complete.

3. Layout horizontal dimensions and initial grade elevations from established lines and benchmarks.

4. Sub-drainage system.

5. Hoisting of pool components and equipment, if required for access to site.

6. Concrete work, including but not limited to, footers for buttress supports, footers for deck equipment, manhole sumps, surge tanks and other cast-in-place or pre-cast concrete members.

7. Storage of pool components and equipment.

8. Framing or sharing of the excavation, as required for installation, including bolt holes for pool anchoring (or concrete support, if applicable.)

9. Perimeter sealant between pool and deck slab.

10. Installation of deck and accessory equipment.

11. Plumbing work, including fresh water and waste lines.

12. Electrical work, including grounding of pool, installation of underwater lights, or other components.

NATARE STAINLESS STEEL SWIMMING POOL SYSTEMS 1315_2 PROJECT NAME Description

13. Paint and coatings of the pool structure or shell are specified herein.

14. Protection during and after installation. a. Immediately after installation, protect pool from damage, contamination, spatter and spillage caused by construction work of other trades. This shall include covering of the pool with protective materials, when necessary and responsibility for prompt repair or corrective measures in the event of damage. b. Do not permit heavy equipment within 10' of pool wall or any pool component. c. Do not permit placement of any acid or alkaline material in contact with the pool structure. d. Do not permit connection or the hanging of pipe, electrical conduit, or other materials to the pool system without prior written approval of the pool installer.

15. Provide verification of initial and ongoing engineering review of structural capacity and integrity of the building to ensure adequacy of the structure to receive the support of the swimming pool.

E. At time of start-up, Owner shall furnish operating personnel, or a designated representative to meet with qualified representative of Manufacturer, who will provide instruction in proper operation of all equipment and systems specified herein.

PART 2 - PRODUCTS

0.1 MANUFACTURER The system specified herein, as manufactured by Natare Corporation of Indianapolis, Indiana, shall be the basis for materials, procedure, and technical quality. 0.2 COMPONENTS Unless otherwise specified, all stainless steel parts are to be fabricated of 12-gauge, low-carbon Type 304 stainless steel, polished to a #3 finish. A. (Optional): The gutter channel shall be covered with a reinforced “T” bar style grating. The grating bearing bars shall be installed parallel with the gutter face and joined by structural fiberglass cross ties every 12". The grating shall sustain a uniform distributed load of 100 pounds per sq. ft. and shall be secured with special stainless steel anchors to prevent vandalism or removal without tools. Grating shall be shipped in 12' long sections. No cycolac, ABS or molded plastic grating of any kind will be acceptable. B. Stainless Steel Supply Tube: The supply tube shall be of the size and configuration detailed on the drawings. The front and top of the supply tube shall form the gutter face and overflow rim, and the back of the supply tube shall form part of the gutter trough. The bottom front of the tube shall form a “V” notch at the point of contact with the pool wall. Jet inlet orifices of 3/8" in diameter shall be drilled in the notch throughout the perimeter of the pool. The orifices shall project downward at 45° angle to assure optimum distribution of the filtered water. There shall be one orifice for every 10-gpm of the recirculation rate. Supply tubes formed from PVC pipe will not be acceptable. The re-circulating tube must have the capability of operating at a pressure of at least 15-psi. All horizontal welds must be accessible for inspection and repair. C. Stainless Steel Gutter Trough: The gutter trough shall be fabricated from a single piece of 12-gauge, low-carbon, Type 304 stainless steel with a #3 polish. This piece shall be formed to the dimensions and configuration detailed on the drawings and shall form a deck trim, as well as the bottom and back of the gutter. The shop-fabricated sections shall be delivered to the jobsite for field installation. The gutter shall be a minimum of ____" deep, measured from the overflow lip to the bottom of the trough, and shall contain a minimum of ____ square inches of cross-sectional area to assure smooth, unimpeded flow of water. PVC piping shall not be utilized for any function within the gutter trough. D. Stainless Steel Wall Panels: The stainless steel sidewall shall be shop-fabricated in a manner to ensure that no cutting by the installer will be necessary in order to meet vertical dimension requirements. The top of each upper wall panel shall have a 45 ° bend in order to form the aforementioned “V” notch when welded to the supply tube. Wall panels shall be fabricated and shipped in at least 10' lengths to minimize welding. E. (Optional) Surge Control Skimming Weirs: The system shall be capable of skimming the water surface through skimming weirs located throughout the pool perimeter, as detailed on the prints. These weirs shall be located within the supply tube below the lip of the perimeter system at the normal pool operating level to allow for ample in-pool surge as the bather load increases. The weirs shall be equipped with an in-gutter, fully automatic surge control device, which operates on hydrostatic principles. These weirs shall act independently according to surge conditions existing in the gutter at each specific point and shall incorporate an automatically adjusting hydrostatic gate to ensure immediate reaction water level changes within the gutter. Each weir shall be capable of skimming 50 gallons per minute, and there shall be enough weirs to continuously skim ____% of the total recirculation rate. F. Stainless Steel Rope Hooks: Rope hooks shall be provided at locations shown on the plans, and shall be made of 3/8" diameter stainless steel rod, welded to the gutter and extending back into the concrete deck for secure attachment. G. Water Surface Agitators and Jet Wash Fittings: Water surface agitators and jet wash fittings shall be supplied at the locations indicated on the plans and shall attach to the gutter in the manner detailed. H. Stainless Steel Collector and Converter Boxes: There shall be ____ stainless steel supply converter box(es) and ____ stainless steel gutter collector box(es) supplied for the recirculation system. (The/Each) supply converter box shall be provided with (a/an) ____ " IPS (flanged) connection. (The/Each) gutter collector box shall be provided with (a/an) ____ " IPS (flanged) connection. I. PVC swimming pool bottom: A complete reinforced PVC membrane lining system specifically designed and formulated for use in swimming pools. The system shall consist of two layers of flexible PVC totally encapsulating a polyester inner reinforcement, in combination with required accessory items to complete the installation. The sections of material shall be fuse-bonded together at the site to form a watertight continuous membrane lining. The system shall be installed in accordance with the configuration as detailed on the drawings, including all necessary equipment within this specification. Individual rolls of reinforced PVC membrane shall be custom fitted and welded together at the job site using hot air welding techniques. Upon completion, the system shall provide a waterproof, yet flexible membrane, complete with all necessary fittings, attachments, flange transitions, and racing lane and target markings. 1. The performance characteristics and installation qualifications as established herein reflect the minimum requirements for any membrane system to be utilized on this project. Systems not meeting the minimum requirements established for this project will not be considered.

NATARE STAINLESS STEEL SWIMMING POOL SYSTEMS 1315_3 PROJECT NAME Description

2. The system specified is based upon the Natatec™ Swimming Pool Membrane System which is a proprietary product of Natare Corporation, located in Indianapolis, Indiana, and the characteristics and standards listed herein. The listed criteria have been established as the minimum acceptable values for any membrane product to be offered on this project. As all aspects and equipment within the pool system have been designed to utilize this system, products not meeting the minimum requirements listed will not be accepted, as that could adversely affect the performance of the system. 3. Source Limitations: Provide all PVC Membrane System components through one source from a single manufacturer. 4. The flexible PVC membrane shall be installed to the dimensions detailed on the drawings and as required. The membrane shall consist of two (2) layers of PVC fuse bonded to a polyester mesh substrate. The membrane shall be no less than 60-mil thick, and shall conform strictly with the following chemical and physical properties as listed herein. Only those membranes specifically formulated for swimming pool use shall be considered. Roofing membranes, general waterproofing membranes, and vinyl liners shall not be acceptable. Additionally, only those swimming pool membranes meeting or exceeding the following ASTM test values, substantiated by independent documentation from a certified testing laboratory, shall be acceptable. This certification will be required before project award. The membrane shall be furnished in a color scheme as detailed by the drawings or in a standard color as selected by the owner. a. Chemical and Physical Properties (MD = machine direction; XD = cross machine direction): 1) Thickness: 60-mil ASTM D374C 2) Specific gravity: 1.22 g/cc ASTM D792/method A 3) Yield tension: MD166 lbs/in - XD284 lbs/in ASTM D638 4) Yield elongation: MD 110% - XD 104% ASTM D638 5) Break tension: MD 51 lbs/in - XD 70 lbs/in ASTM D638 6) Break elongation: MD 181% - XD 132% ASTM D638 7) Secant modulus MD 1352 psi - XD 1125 ASTM D5323 (100%): 8) Tear resistance: MD 18.2 lb. - XD 24.7 lb. ASTM D1004- Die C 9) Low temp. brittleness -50°C Pass ASTM D1790 10) Water absorption: 0.78% ASTM D570 11) Puncture Resistance: 125 lbs ASTM D4833 12) UV Resistance: ASTM D4355 13) Tensile Strength @ Yield MD 23% - XD 16% 14) Tensile Strength @ Break MD 301% - XD 323% (% Change) All values subject to a ± 10% variance.

5. A slip resistant reinforced PVC membrane, .067 inch thick, and identical in chemical and physical properties to the flexible reinforced PVC membrane described above, which includes a specifically designed embossed surface suitable for high traffic areas, shall be installed as detailed on the drawings. The slip-resistant surface shall be certified by independent ASTM Laboratory testing to comply with the requirements of ASTM C1028. Furnish in the color scheme as detailed by the drawings or as selected by the owner.

6. Separator Fleece: The interior surfaces of the swimming pool shall be covered with an engineered polyester fleece separator, a minimum of 150 mils in thickness, weighing at least 10.5 ounces per square yard. The fleece separator must be resistant to freeze thaw, moisture, soil-chemical abrasion, or ultraviolet deterioration and shall conform strictly to the following chemical and physical properties. All fleece separators shall be certified and guaranteed to be free of foreign materials, which could potentially be damaging to the liner. 7. PVC Steel Edging: An epoxy coated stainless steel sheet, at least 20 gauge with PVC laminated to one side shall be used to form edges, angles, corners, or other transitions where a firm surface is necessary to weld the PVC membrane. 8. Isolating Sheet: At least 20-gauge stainless steel sheet shall be used as required for reinforcement, shaping, or separation as required. It shall be installed over expansion joints when sealants or caulking has been installed. 9. Sanitizing Agents: Sanitizing agents, formulated from a mixture of halogenated organic compounds, and specifically designed for this purpose, shall be applied to the pool surface, beneath the pool liner, to prevent the growth of microbes or fungus. 10. Transition Flanges: Compression flanges fabricated of rigid, white polymer, ¼-inches thick, shall be furnished at all membrane penetrations or openings to the swimming pool. All transition flanges shall be secured with stainless steel anchoring systems. 11. Edge Sealant: Liquid PVC edge sealant solution shall be applied to all free material edges after welding. This process is to provide a properly detailed edge on material lap joints. Only those membrane systems utilizing an edge sealant solution will be considered, as this process is critical to the overall durability of the membrane. J. Targets and markings: 1. The swimming pool shall have swimming lane racing targets located as required and shall conform to the applicable rules as designated by United States Swimming Inc. (USS), National Collegiate Athletic Association (NCAA), or the Federation Internationale de Natation Amateur (FINA) as designated by the Architect, Engineer or Consultant. The targets shall consist of permanent black slip-resistant PVC that shall be incorporated on to the surface of the wall panels or PVC floor system at the specified locations. Paints or coating systems shall not be used for target markings.

K. (Optional) Stainless Steel Pool Floor: The stainless steel pool floor or (bottom) shall consist of leveled and trued sheets of 12-gauge, low- carbon, Type 304 stainless steel, with a 2B finish. It shall join the pool sidewall via a 2" angular cover, which intersects the sidewall at the floor junction. Where applicable, it shall break into the diving well. L. (Optional) Underwater Lights: Underwater lights and niches shall be provided at locations shown on the plans. M. (Optional) Integral Perimeter Deck Drain: The integral perimeter deck drain shall be continuous around the periphery of the swimming pool and shall be formed from a specially-fabricated stainless steel section which shall join to the back of the gutter. It shall consist of straight parallel sections continuously welded to the gutter section to provide a continuous opening of approximately 1/4". It shall be secured by

NATARE STAINLESS STEEL SWIMMING POOL SYSTEMS 1315_4 PROJECT NAME Description

spacer rods located approximately 1' on center. Outfall box(es) with flange connections shall be provided for the continuation by others of the deck drain waste line to sewer, sump, or other outfall. N. (Optional) Stainless Steel Steps: Recessed steps are to be fabricated of 12-gauge, low-carbon, Type 304 stainless steel. The tread, or bottom inside surface, is to be coarse sand blasted so as to provide a non-skid surface. All other portions of the step shall have a 2B finish. All exposed joints are to be Heliarc welded and ground smooth. O. (Optional) Recessed stainless Steel Stairway: A recessed stairway shall be furnished to the dimensions and configuration detailed on the drawings. The stairway shall be fabricated from the same grade of material as the wall and gutter. Stairway shall be supported by an integral mild steel support system and buttress. Stairway shall include provisions for attachment of handrail, if necessary. Provide appropriate transition sections so as not to interfere with perimeter system operation. 0.3 WARRANTIES AND GUARANTEES The swimming pool system shall be guaranteed by the manufacturer for workmanship, material and performance for a period of five (5) years. Guarantee shall include all labor and material for replacement of any defective material or work, but shall not include or cover abusive or improper treatment to the re-circulating system by others during the construction period and/or when operational. 0.4 ENGINEERING SERVICES The pool system supplier shall provide a full set of fabrication and installation drawings, certified if requested; showing all features of the system construction and indicating proper sizing and locations along with complete dimensional details. The equipment manufacturer shall supply the services of a competent and experience field engineer for a period of at least three (3) days to inspect the completed installation, adjust the automatic controls to the proper set points, place the system in operation and give operating instructions relative to its care and use.

PART 3 - GENERAL 0.1 All work under this section shall be performed by an authorized licensee of the system’s manufacturer or as directed by said licensee so that the complete system will operate in accordance with the intent of the Specifications and to provide the Owner with a safe, economic, operating and sanitary swimming/diving facility. 0.2 All equipment unloading, storage and installation is to be the responsibility of the General or Pool Contractor. Proper care is to taken at all times to protect the equipment from exposure and handling damage.

0.3 INSPECTION

The system installation shall inspect all previous and contiguous work for dimensional accuracy and/or other variations that will adversely affect the execution and/or quality of the swimming pool system.

A. Grade tolerance for swimming pool bottom base at pool wall line with reference to benchmark shall be ± ½.

B. Report unsatisfactory conditions to the proper authority. The swimming pool system installer shall not start work until all conditions are corrected by trade or trades responsible.

0.4 Additional foundation and/or structural work required for the placement and operation of systems, other than that so noted herein or on the drawings, shall be provided at the direction of the swimming pool installer under this Contract.

0.5 The Contractor shall provide a properly prepared sub-base consisting of uniformly graded granular material guaranteed to be iron-free. Over excavate the natural soils beneath the pool a minimum of 2'. The excavation shall extend a minimum of 3' horizontally beyond all edges of the pool foundation system. The sub-grade shall then be scarified a minimum of 12" and densified to a minimum 90% modified proctor density in accordance with ASTMD-1557. Place structural fill to within 12" of the bottom of the pool floor utilizing the over excavated material in lifts not exceeding 6". The structural fill shall be brought to with -2% to +4% of the optimum moisture content and then re-compacted as specified above. Place a 12" gravel layer immediately atop the structural fill. The cohesionless material should be clean gravel or uniformly graded material, iron-free, with a 3/4" maximum size of aggregate. All gravel material shall be densified to a 60% relative density in accordance with ASTMD-2049. Slope all gravel materials in accordance with drawings to the lowest point beneath the pool.

Contractor shall furnish written certification to the swimming pool system installer that the backfill and sub-base are in accordance with the above Specifications.

The sub-base shall be graded to pool dimensions as indicated on the plans. All slopes and transitions shall be formed by the Contractor in accordance with the dimensions as shown on the plans. Slopes shall be formed and maintained through the use of continuous screed boards at any point where the slop exceeds 30°. Screed boards shall be CCA treated lumber and shall be anchored using rebar driven into sub-base to a minimum of 3'.

A. The swimming pool system installer shall erect the A-frame buttress support system after the buttress anchors have been installed in the concrete footer and the footer fully cured.

B. Entire system is to be set level, true and square to dimensions as noted on drawings.

C. The joint between the pool deck and the gutter channel shall be an expansion joint, allowing the deck to expand or move independently of the gutter channel. The top edge of the joint shall be filled with a Thiokol (polysulfide)-based caulking and sealing compound equal to “Sikaflex 1A” to a depth and width of ½."

D. All installation is to be performed by skilled technicians (welders with at least five (5) years experience in field welding stainless steel recirculation systems). If requested, the Contractor shall submit the installer’s experience in writing to the Architect for approval prior to ordering the re-circulating system. All work is to be performed in accordance with manufacturer’s technical bulletins. Should the requirement of these bulletins contradict this or any other section of the Specifications, the procedures called for in the bulletin shall govern.

E. All welding shall be performed in accordance with the procedures established by the American Standards Association. All exposed weld beads shall be cleaned to a smooth uniform non-corrodible finish. All exposed weld beads shall be flush, smooth, and uniform with minimum irregularities. All spatter must be removed. Welds shall be cleaned, and all burn and discoloration removed. Interior welds made on the

NATARE STAINLESS STEEL SWIMMING POOL SYSTEMS 1315_5 PROJECT NAME Description

underside of an exposed surface must be completed so that there is no noticeable discoloration, burn-through, or sugaring on the exposed face. No grinding of any welds will be permitted.

F. Installation shall be performed by a licensee of the manufacturer. The stainless steel sidewalls shall be erected on a heavy steel frame consisting of a series of structural angle buttresses welded to anchors embedded in a reinforced concrete footing which is poured continuously round the entire outside of the pool perimeter by the General Contractor. Buttresses shall be erected a maximum of 5' apart and shall be bitumastic-coated after installation.

G. The stainless steel sidewalls and circulation system shall be entirely shop-fabricated in at least 10' sections. These sections shall be brought to the jobsite and welded to the frame assembly to form a continuous, smooth, strong, leak-proof wall. All welds shall be as detailed in Item #4 above.

H. After the wall is erected, the swimming pool floor should be installed utilizing level, and trued sheets of low-carbon, Type 304 stainless steel.

I. Upon completion of wall and gutter installation, the supply tube shall be pressure tested (before the jet inlets have been drilled). The supply tube shall be supplied with 15-psi air pressure and shall be maintain 15-psi for four hours. During the four-hour period, all joints shall be soap tested. Pressure testing shall be done by the installer.

J. Immediately following pressure testing, the pool bottom shall be sand blasted using iron-free silica sand to remove any weld scale and provide a uniform, brushed finish for the pool bottom.

K. Immediately following sand blasting, the entire system shall be cleaned and passivated by washing with an acid solution to remove carbide and scale impurities and establish a chromium oxide coating on the stainless steel.

L. After the stainless steel re-circulating system has been installed on the pool wall, the General Contractor (Division 3 Work) or the Pool Contractor shall form a joint between the pool deck and the gutter channel which shall be an expansion joint allowing the deck to expand or move independently of the gutter channel. The top edge of the joint shall be filled with a Thiokol (polysulfide)-based sealing compound equal to “Sikaflex 1A.” This seal shall have a minimum depth and width of ½".

M. The installation shall be in accordance with approved shop drawings which shall be furnished by the swimming pool system's manufacturer. The pre-fabricated bottom and sidewall sections shall be carefully placed, leveled and aligned, assembled and welded, braced and anchored to the embedded anchors. Pool walls and perimeter overflow lip shall straight, plumb and level within specified tolerances.

1. Vertical tolerance for pool walls and perimeter systems shall be ± ¼" per 100' lineal dimension.

2. Horizontal tolerance for gutter overflow lip and gutter members shall be ± ¼" per 100'.

3. Horizontal tolerance for swimming pool bottom when filled and ready for operation shall be ± 1" with reference to benchmark or pool water line.

0.6 FIELD QUALITY CONTROL

All field welds shall be tested with the procedure equivalent to the use of water-washable dye check penetrating procedure, utilizing WWI red penetrating liquid to reveal pinholes, surface cracks and similar defects. Procedure includes pre-cleaning, dry application, rinsing, drying, developing and final rinsing. A field test of all peripheral lines shall be completed as detailed earlier in this Specification.

NATARE STAINLESS STEEL SWIMMING POOL SYSTEMS 1315_6 Natare Corporation 5905 W. 74th Street • Indianapolis, IN 46278 • USA (800) 336-8828 • (317) 290-8828 • FAX (317) 290-9998 www.natare.com • [email protected]

This information in this document is proprietary, confidential and is the exclusive property of Natare Corporation. These materials are not considered published and are provided for the exclusive use of the intended recipient for the intended use in conjunction with equipment, systems or services provided by Natare, and they may be copied or distributed to third parties for that purpose. ©Natare Corporation 1997-2008. All rights reserved.