21 - Transmission and Transfer Case/Automatic - 62TE/Removal REMOVAL

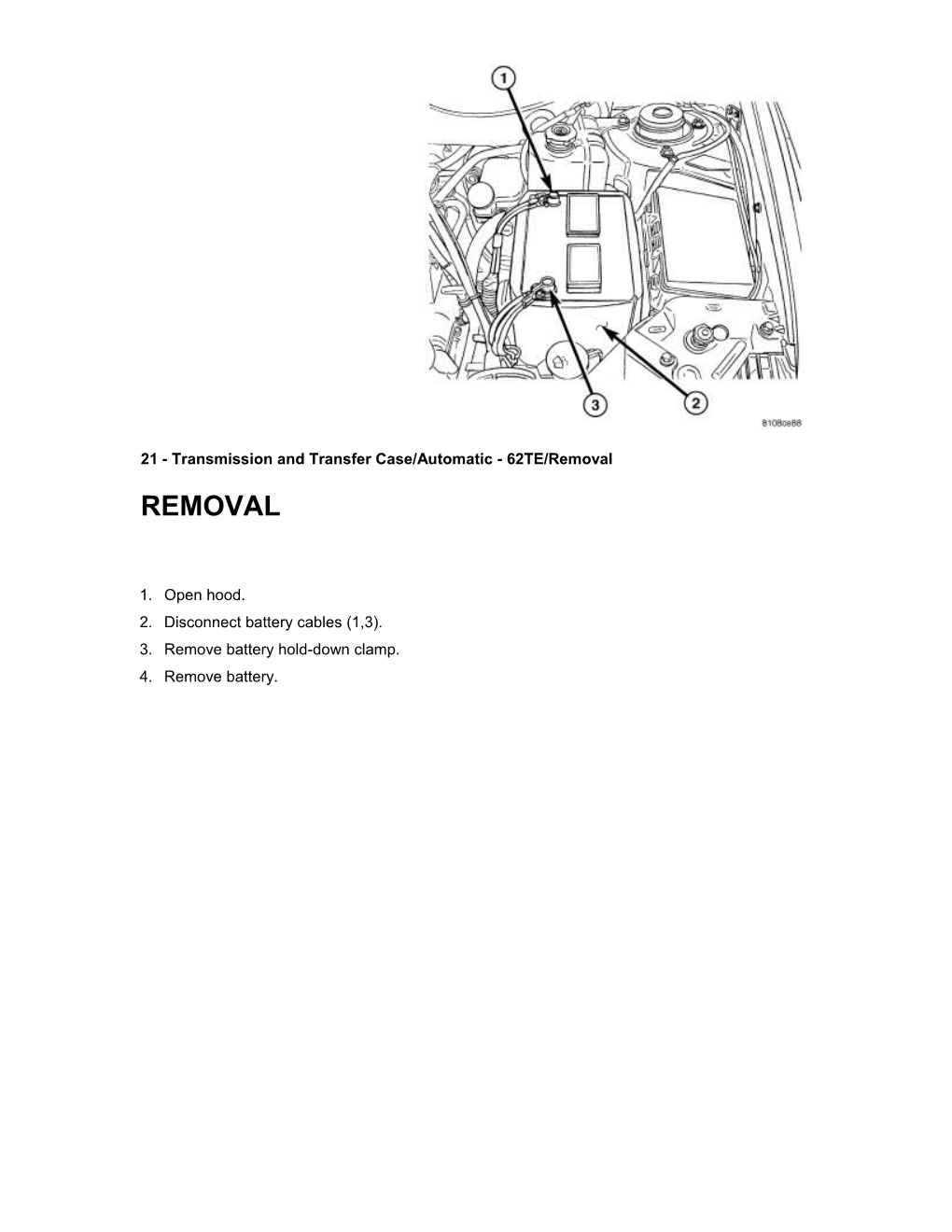

1. Open hood. 2. Disconnect battery cables (1,3). 3. Remove battery hold-down clamp. 4. Remove battery. 5. Remove battery tray bolts (3). 6. Remove battery tray (2).

7. Disconnect gearshift cable (1) from transaxle manual valve lever (2). 8. Disconnect the electrical connector (2) at the crankshaft position sensor (3). 9. Remove hold down bolt (1) at the crankshaft position sensor. 10. Remove the crankshaft position sensor (3). 11. Disconnect input speed sensor connector.

12. Disconnect oil cooler lines from transaxle using Tool 8875A . 13. Remove the bolt (2) holding the ground cable (3) to the transaxle case. 14. Remove clip (1) at valve body pan.

15. Disconnect both output speed sensor connectors (1, 2). 16. Disconnect solenoid/pressure switch assembly connector (2).

17. Release transaxle harness (1) from retainers and position out of way . 18. Remove coolant bypass tube-to-engine and transaxle fasteners. 19. Disconnect front brake lines (1) from the hydraulic control unit . Position out of way for removal clearance.

20. Remove intermediate shaft extension (4) from steering gear (3). 21. Remove roll pin (2) using Remover 6831A . 22. Slide shaft extension (1) off of gear (3).

23. Install overhead powertrain support fixture Tool 8534B and adapter kit 8534-12 . 24. Remove engine oil dipstick tube-to-cylinder head fastener. Install lift/support bracket 8534- 8 and secure with dipstick tube bolt.

25. Disconnect coolant temperature sensor (at thermostat housing). Remove engine harness-to- cylinder head bolt. Position harness out of the way. Install and secure lift/support bracket 8534-7 and bolt. 26. Assemble 8534-2 mounting bracket/sleeve assemblies to support tube 8534-1and install to vehicle, allowing brackets to rest on inner fender ledges.

27. Assemble cross-bar 8534-3 , clamp 8534-5 and support leg 8534-4 to support tube, allowing support leg to rest on radiator upper support. 28. Tighten cross-bar-to-support tube clamp 8534-5 , as well as mounting bracket/sleeve 8534- 2 thumb screw and hex nut to secure fixture.

29. Tighten thumb screw and pivot nut on fixture. 30. Install lift bracket/hook assemblies.

31. Tighten t-handles just enough to build tension between the fixture and drivetrain. 32. Raise vehicle on hoist. 33. Remove the nut (1) at the sway bar link (3). 34. Disconnect sway bar links (3) from struts (2).

35. Remove both front tire/wheel assemblies. 36. Remove the bolts (1) at the ABS sensors (2). 37. Remove sensors (2) from the knuckles (1). .

38. Remove front halfshaft assemblies (Refer to 03 - Differential and Driveline/Half Shaft - Removal) . 39. Remove engine front and rear mount-to-cradle nuts. 40. Disconnect brake hydraulic line and brackets from frame rails. 41. Disconnect power steering hydraulic line bracket (4) at cradle on passenger side. 42. Disconnect four Chassis brake tubes (1, 2, 3, 4) at ABS ICU (5). Cap off brake tubes and install sealing plugs in open brake tube outlet ports of ICU.

43. Disconnect power steering pressure and return lines (2,3 and 4) from steering gear (1). 44. Cap lines to prevent debris intrusion and tie out of way. 45. Set Driveline Support Table 8874 into position.

46. Lower vehicle until cradle and fixture engage. 47. Scribe alignment marks to reference the cradle to the body for installation. Remove cradle-to- body bolts. 48. Slowly raise vehicle on hoist to separate cradle from vehicle. Verify that overhead fixture is secure to inner fenders and radiator upper support.Have helper guide brake and power steering hydraulic lines through, as they will remain attached to cradle assembly. 49. Remove engine front mount/bracket (1).

50. Disconnect starter motor electrical connectors. Remove starter motor and shim (Refer to 08 - Electrical/Starting/STARTER - Removal) . 51. Remove propeller shaft assembly (Refer to 03 - Differential and Driveline/Propeller Shaft - Removal) . 52. Remove PTU from vehicle (Refer to 21 - Transmission and Transfer Case/Power Transfer Unit - Removal) . 53. Remove bolts and bracket (3) to exhaust bracket. 54. Remove bolts (2) to stand off bracket (4). 55. Remove bracket (4).

56. Remove torque converter dust shield bolt (3). 57. Remove torque converter dust shield (2). 58. Remove the torque converter-to-driveplate bolts (1). Upon removing bolts, a tight-tolerance (slotted) bolt will be encountered. Mark this location (driveplate and converter) with paint for assembly reference.

59. Lower vehicle. 60. Remove the transaxle upper bellhousing-to-block bolts (3). 61. Lower engine/transaxle at overhead fixture. 62. Raise vehicle. 63. Install transmission jack into position. Secure transaxle to jack.

NOTE: The bolts on each side of the inspection opening were removed with the exhaust bracket. 64. Remove the transaxle-to-engine lower bolts (2). 65. Lower transaxle from engine compartment.