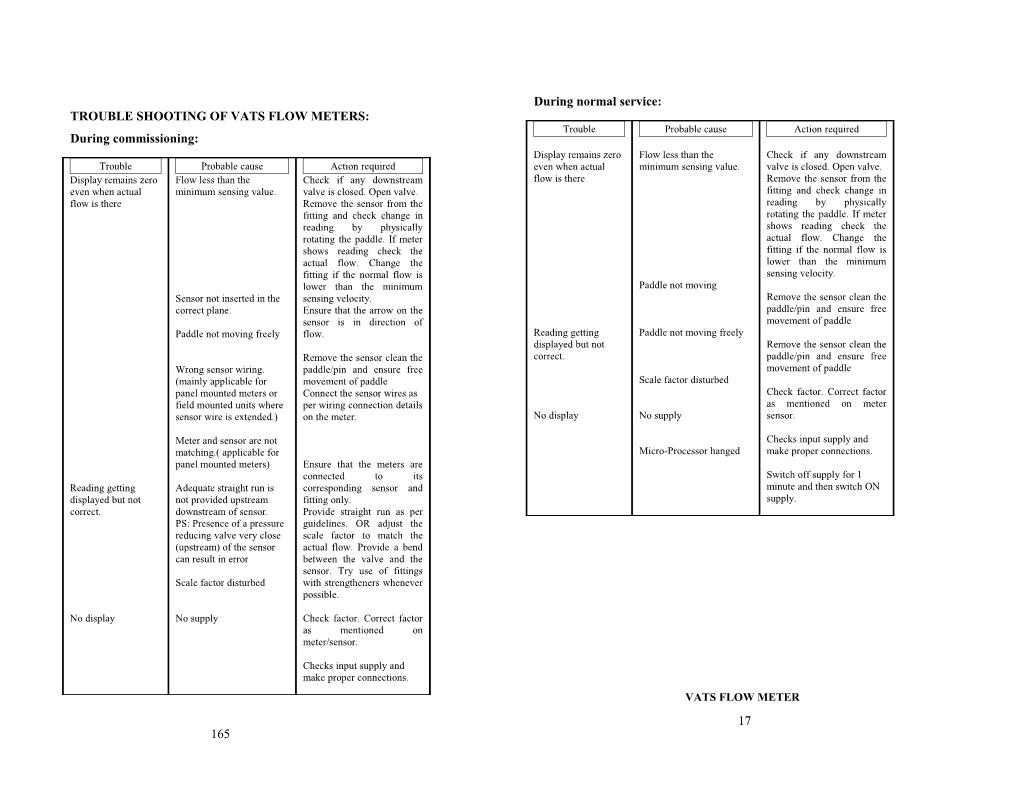

During normal service: TROUBLE SHOOTING OF VATS FLOW METERS: Trouble Probable cause Action required During commissioning: Display remains zero Flow less than the Check if any downstream Trouble Probable cause Action required even when actual minimum sensing value. valve is closed. Open valve. Display remains zero Flow less than the Check if any downstream flow is there Remove the sensor from the even when actual minimum sensing value. valve is closed. Open valve. fitting and check change in flow is there Remove the sensor from the reading by physically fitting and check change in rotating the paddle. If meter reading by physically shows reading check the rotating the paddle. If meter actual flow. Change the shows reading check the fitting if the normal flow is actual flow. Change the lower than the minimum fitting if the normal flow is sensing velocity. lower than the minimum Paddle not moving Sensor not inserted in the sensing velocity. Remove the sensor clean the correct plane. Ensure that the arrow on the paddle/pin and ensure free sensor is in direction of movement of paddle Paddle not moving freely flow. Reading getting Paddle not moving freely displayed but not Remove the sensor clean the Remove the sensor clean the correct. paddle/pin and ensure free Wrong sensor wiring. paddle/pin and ensure free movement of paddle (mainly applicable for movement of paddle Scale factor disturbed panel mounted meters or Connect the sensor wires as Check factor. Correct factor field mounted units where per wiring connection details as mentioned on meter sensor wire is extended.) on the meter. No display No supply sensor.

Meter and sensor are not Checks input supply and matching.( applicable for Micro-Processor hanged make proper connections. panel mounted meters) Ensure that the meters are connected to its Switch off supply for 1 Reading getting Adequate straight run is corresponding sensor and minute and then switch ON displayed but not not provided upstream fitting only. supply. correct. downstream of sensor. Provide straight run as per PS: Presence of a pressure guidelines. OR adjust the reducing valve very close scale factor to match the (upstream) of the sensor actual flow. Provide a bend can result in error between the valve and the sensor. Try use of fittings Scale factor disturbed with strengtheners whenever possible.

No display No supply Check factor. Correct factor as mentioned on meter/sensor.

Checks input supply and make proper connections. VATS FLOW METER 17 165 Check Sheet (Use of tester does not confirm proper neutral or adequate voltage) General Water deposition inside the meter housing Y/N For Ultraflo, remove the front cover and replace the battery by an Alkaline Date: 9VBattery the unit started displaying flow Y/N The back light gets on (for A110/A210/J210/J510) Y/N Name of Client/Dealer: The last led of the BAR Graph ( for A050) blinks when the paddle is rotated Y/N

Serial Number: No. of months in use: B ) Reading remains zero Model: Ultraflo Rate Indicator(field mounted) A110 [ ] Checked actual flow and found it higher than the minimum capacity of the meter Fluid monitor LCD indicator cum totaliser A210 [ ] / J210 [ ] Y/N LED bargraph batcher model A050 [ ] Removed the flow sensor from the fitting and checked free rotation of paddle Flow transmitter model J510 [ ] wheel Y/N OR Meter showed reading when paddle rotated by hand Y/N Model: Rate Indicator (field Mounted) IP 110 [ ] For panel mounted meters checked the sensor wiring to the terminal strip. All the Rate cum electromechanical totaliser IP 210 [ ] three wires were connected to the respective terminals Y/N Rate indicator panel mounted JT110 [ ] / JT 111 [ ] (If the same site has more than one panel meters) Connected another sensor of the Rate cum total panel JT 210 [ ] working unit to the meter. Meter shows reading Y/N The last led of the BAR Graph ( for A050) blinks when the paddle is rotated Y/N Installation fitting Type: Checked scale factor programmed and found it to be same as written on the meter Y/N Polypropylene wafer fitting [ ] , Plastic Tee fitting [ ] , Stainless steel weld on fitting.[ ] , Flow straightened pipe fitting [ ]. C ) Fluctuating reading: Installation/Location: Outdoor [ ] /Indoor [ ] Is the sensor located just after any valve/reducer? Y/N Removed the sensor found the paddle moving freely Y/N Application: Deminraliser [ ], RO [ ], Blending- Mineral water [ ] Did not find any air bubbles in the water line Y/N Other – specify ______ (For panel meters) checked the sensor wiring and tightened all the three wires to the respective terminals of the strip. Y/N Line pressure: ______kg/cm2 max. Is the sensor wiring is extended. Y/N The wiring is properly extended and there is no shorting of wires Y/N

Types of Problems D ) Steady but erroneous reading: A ) No display [ ] Mention the flow rate indicated w.r.t. actual ______. B ) Reading remains Zero [ ] The Serial number of the meter, sensor and fitting were matching Y/N C ) Fluctuating reading [ ] Line size mentioned on the indicator same as the fitting Y/N D ) steady but erroneous reading [ ] Scale factor of the meter same as that mentioned on the sticker Y/N E ) Breakage [ ] There is an adequate straight run on the inlet/ outlet of the sensor ( refer guidelines F ) Gradual fading of display [ ] enclosed) Y/N G ) meter shows reading even at no flow (applicable for IP/JT series only) If straight run inadequate adjust scale factor to match the actual flow. Readings H ) any other- specify [ ] found OK Y/N E ) Breakage: A ) No Display Specify the component broken and the likely cause for the same- Check for power supply using multi meter/test lamp [ ] F ) Gradual fading of display:

The unit is exposed to direct sunlight. Y/N

G ) Meter shows reading even at no flow (applicable for IP and JT series only): There is an induction motor/coil very close to meter/sensor Y/N For JT series. The T-50/Cal key is in released position Y/N The extra sensor cable is kept looped near the Sensor Y/N The plant piping was properly grounded. Y/N Sensor removed from fitting. Meter reading became zero Y/N Disconnect the sensor wires from meter. Reading becomes zero Y/N

H ) Any other: Specify_____

Checklist filled by: Company name:

Manufacturer & Marketed by: VATTURKAR INDUSTRIAL B14/3 , Bandhan Society , Kothrud, Pune- 29 Tel-091-020-25430897, Telfax- 25432157. [email protected] WEB- www.vatsmeter.com