1 AGENDA ITEM- 620- 274 June 29, 2004

Title: Thickness Limitations and Impact Test for Basic API-620 Tanks

Source: B. Mistry E-Mail May 10,2004

Purpose: To clarify thickness limitations and notch toughness for basic API-620 Tanks. Revise 4.2.1.2, 4.2.3.2 and 4.2.5, Add Table 4-3.

Contact: Bhana Mistry TIW Steel Platework Tel: 905-684-9421 Fax: 905-684-7310 Email: [email protected]

Technical Justification: Present text in 4.2.3.2 and 4.2.5 is difficult to follow and interpret.

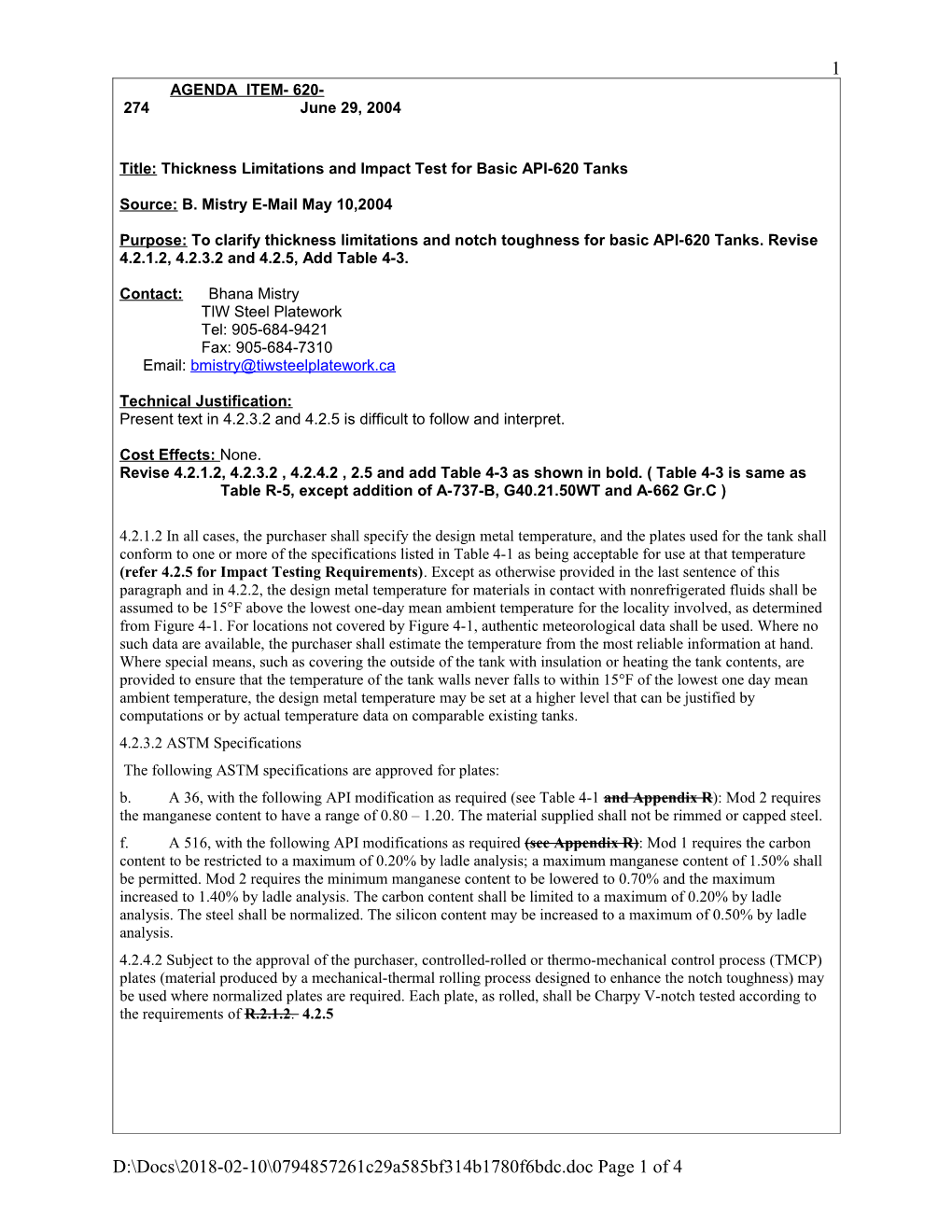

Cost Effects: None. Revise 4.2.1.2, 4.2.3.2 , 4.2.4.2 , 2.5 and add Table 4-3 as shown in bold. ( Table 4-3 is same as Table R-5, except addition of A-737-B, G40.21.50WT and A-662 Gr.C )

4.2.1.2 In all cases, the purchaser shall specify the design metal temperature, and the plates used for the tank shall conform to one or more of the specifications listed in Table 4-1 as being acceptable for use at that temperature (refer 4.2.5 for Impact Testing Requirements). Except as otherwise provided in the last sentence of this paragraph and in 4.2.2, the design metal temperature for materials in contact with nonrefrigerated fluids shall be assumed to be 15°F above the lowest one-day mean ambient temperature for the locality involved, as determined from Figure 4-1. For locations not covered by Figure 4-1, authentic meteorological data shall be used. Where no such data are available, the purchaser shall estimate the temperature from the most reliable information at hand. Where special means, such as covering the outside of the tank with insulation or heating the tank contents, are provided to ensure that the temperature of the tank walls never falls to within 15°F of the lowest one day mean ambient temperature, the design metal temperature may be set at a higher level that can be justified by computations or by actual temperature data on comparable existing tanks. 4.2.3.2 ASTM Specifications The following ASTM specifications are approved for plates: b. A 36, with the following API modification as required (see Table 4-1 and Appendix R): Mod 2 requires the manganese content to have a range of 0.80 – 1.20. The material supplied shall not be rimmed or capped steel. f. A 516, with the following API modifications as required (see Appendix R): Mod 1 requires the carbon content to be restricted to a maximum of 0.20% by ladle analysis; a maximum manganese content of 1.50% shall be permitted. Mod 2 requires the minimum manganese content to be lowered to 0.70% and the maximum increased to 1.40% by ladle analysis. The carbon content shall be limited to a maximum of 0.20% by ladle analysis. The steel shall be normalized. The silicon content may be increased to a maximum of 0.50% by ladle analysis. 4.2.4.2 Subject to the approval of the purchaser, controlled-rolled or thermo-mechanical control process (TMCP) plates (material produced by a mechanical-thermal rolling process designed to enhance the notch toughness) may be used where normalized plates are required. Each plate, as rolled, shall be Charpy V-notch tested according to the requirements of R.2.1.2. 4.2.5

D:\Docs\2018-02-10\0794857261c29a585bf314b1780f6bdc.doc Page 1 of 4 2

D:\Docs\2018-02-10\0794857261c29a585bf314b1780f6bdc.doc Page 2 of 4 3 4.2.5 Impact Test Specimens Requirements for Plates 4.2.5.1 Table 4-1 provides exemption and impact testing requirements of plates for various grades for given thickness range and design metal temperature. However, any material listed in Table 4-1 can be used for any thickness and temperature provided the material meets impact test requirements as specified in 4.2.5 and Table 4-3 and welding procedure requirements specified in 6.7. When the plate is not exempted from impact testing per required by Table 4-1, each plate shall be impact tested; plate refers to the unit plate rolled from a slab or directly from an ingot. The ASTM A 370, Type A, Charpy V-notch test shall be used. The long dimension of the specimen shall be parallel to the direction of the expected maximum stress. When the coincident stresses are approximately equal, the specimens shall be taken transverse to the final direction of the plate rolling. The requirements of R.2.1.2 shall be satisfied, except that the The minimum energy absorption values of Table R-5 4-3 may be substituted for those of Table R-2. shall be satisfied. 4.2.5.2 For sub-size specimen acceptance criteria, see ASTM A 20. An impact test temperature lower than the design metal temperature may be used by the manufacturer, but in such a case the impact values at the test temperature must comply with Table 4-3 4.2.5.3 All other impact requirements of ASTM A 20, Supplementary Requirement S 5, shall apply for all materials listed in Table 4-3, including specifications that do not refer to ASTM A 20. 4.2.5.4 For thickness exceeding the range in Table 4-3, impact test requirements shall be mutually agreed upon between the manufacture and the purchaser.

D:\Docs\2018-02-10\0794857261c29a585bf314b1780f6bdc.doc Page 3 of 4 4

Table 4-3 Minimum Charpy V-Notch Requirements for Plate Specimens Impact Valuea Range in Specification Thickness (foot-pounds) Group Number Grade (in.) Average Individual b 3 I (semikilled) A36 Mod 2 /16 – 1 13 9 3 A131 B /16 – 1 13 9 3 1 ISO 630 E275 Quality C /16 – 1 /2 13 9

c 3 1 II (fully killed) A573 58 /16 – 1 /2 15 10 3 1 A131 CS /16 – 1 /2 15 10 3 A516 55 and 60 /16 – 2 15 10 d 3 1 A516 55 and 60 /16 – /2 15 10 3 1 ISO 630 E275 Quality D /16 – 1 /2 15 10 3 CSA G40.21 38WT /16 – 2 15 10

3 III (fully killed A573 65 and 70 /16 – 2 15 10 3 and high A516 65 and 70 /16 – 2 15 10 b 3 Strength) A516 65 and 70 Mod 1 /16 – 2 15 10 b 3 A516 65 and 70 Mod 2 /16 – 2 15 10 3 A537 1 /16 – 2 15 10 3 A537 2 /16 – 2 20 15 3 A633 C and D /16 – 2 15 10 3 A662 B and C /16 – 2 15 10 3 1 A678 A /16 – 1 /2 20 15 3 A678 B /16 – 2 20 15 3 ISO 630 E355 Quality D /16 – 2 15 10 3 CSA G40.21 44WT /16 – 2 15 10 3 CSA G40.21 50WT /16 – 2 15 10 3 A737 B /16 – 2 15 10 3 A841 1 /16 – 2 15 10

Notes: aThe stated values apply to full-sized specimens. For sub-size specimen acceptance criteria, see ASTM A 20. An impact test temperature lower than the design metal temperature may be used by the manufacturer, but the impact value at the test temperature must comply with Table 4-3. When plate is selected, consideration must be given to the possible degradation of the impact properties of the plate in the weld heat-affected zone. bSee 4.2.3 for a complete description of this material. c 3 The steel shall be fully killed and made with fine-grain practice, without normalizing, for thicknesses of /16 in. – 1 1 /2 in. dThe manganese content shall be in the range from 0.85% to 1.20% by ladle analysis.

D:\Docs\2018-02-10\0794857261c29a585bf314b1780f6bdc.doc Page 4 of 4