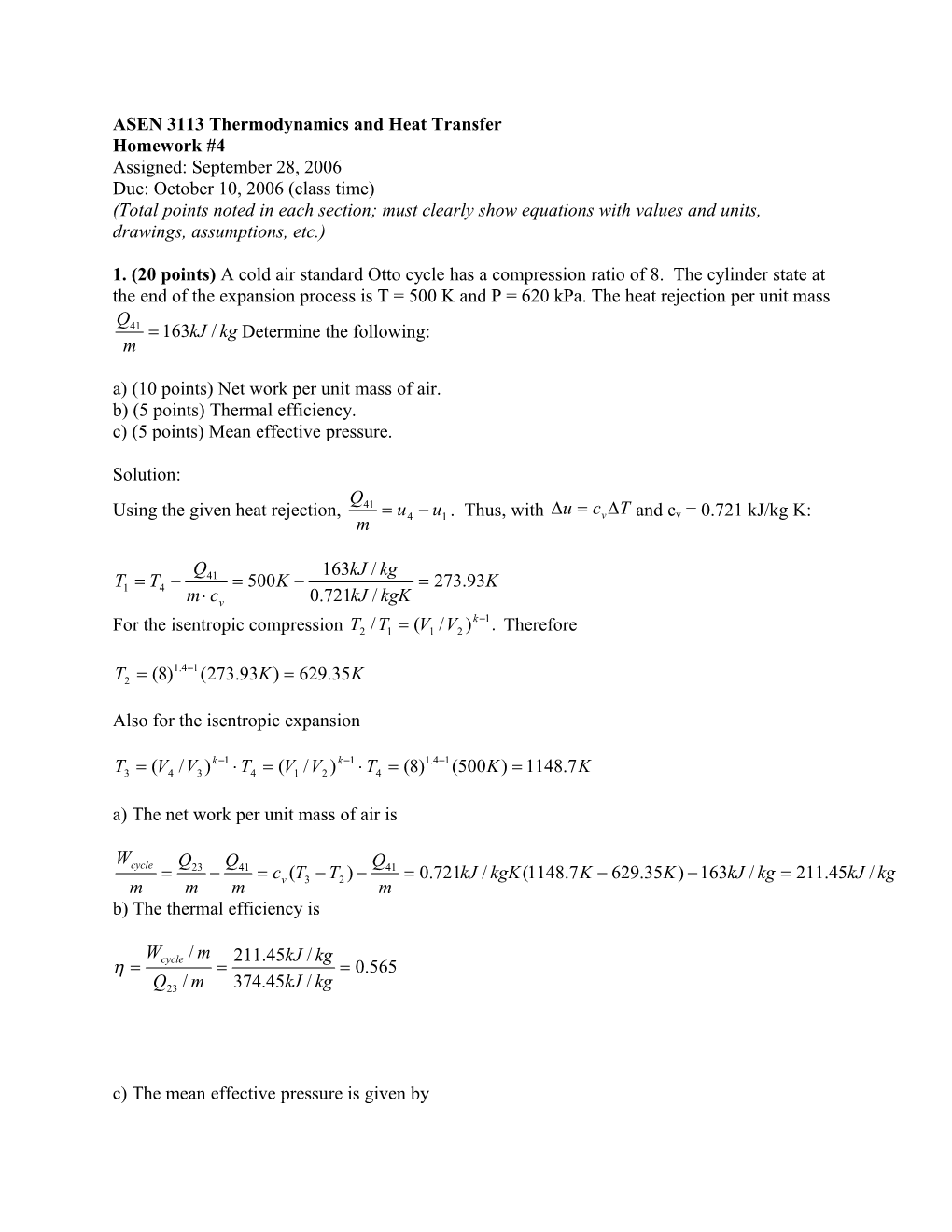

ASEN 3113 Thermodynamics and Heat Transfer Homework #4 Assigned: September 28, 2006 Due: October 10, 2006 (class time) (Total points noted in each section; must clearly show equations with values and units, drawings, assumptions, etc.)

1. (20 points) A cold air standard Otto cycle has a compression ratio of 8. The cylinder state at the end of the expansion process is T = 500 K and P = 620 kPa. The heat rejection per unit mass Q 41 163kJ / kg Determine the following: m a) (10 points) Net work per unit mass of air. b) (5 points) Thermal efficiency. c) (5 points) Mean effective pressure.

Solution:

Q41 Using the given heat rejection, u u . Thus, with u c T and cv = 0.721 kJ/kg K: m 4 1 v

Q41 163kJ / kg T1 T4 500K 273.93K m cv 0.721kJ / kgK k 1 For the isentropic compression T2 /T1 (V1 /V2 ) . Therefore

1.41 T2 (8) (273.93K) 629.35K

Also for the isentropic expansion

k 1 k1 1.41 T3 (V4 /V3 ) T4 (V1 /V2 ) T4 (8) (500K) 1148.7K a) The net work per unit mass of air is

W Q Q Q cycle 23 41 c (T T ) 41 0.721kJ / kgK(1148.7K 629.35K) 163kJ / kg 211.45kJ / kg m m m v 3 2 m b) The thermal efficiency is

W / m 211.45kJ / kg cycle 0.565 Q23 / m 374.45kJ / kg

c) The mean effective pressure is given by W W mep cycle cycle V1 V2 V1 (11/ r)

Evaluating the specific volume V1=V4

RT4 (0.2870kJ / kgK)(500K) 3 Where V4 0.2315m / kg P4 620kPa

211.45kJ / kg Thus mep 1043.86kPa (0.2315m3 / kg)(11/ 8)

2. (20 points) An air standard gas turbine engine has a compressor pressure ratio of 12. It operates between 290 K and 1400 K. The turbine and compressor each have isentropic efficiencies of 90%.Determine the following: a) (10 points) Net work per unit mass of air flow. b) (5 points) Heat rejected per unit mass flow of air. c) (5 points) Thermal efficiency.

Solution: Determine the unknown temperatures:

(k1) / k P 2 (1.41) /1.4 T2 T1 290K12 589.84K P1

(k 1) / k P 4 (1.41) /1.4 T4 T3 1400K1/12 688.32K P3 Determine the work input to the compressor and the work output of the turbine:

Win c p (T2 T1 ) (1.005kJ / kgK)(589.84K 290K) 301.34kJ / kg

Wout c p (T3 T4 ) (1.005kJ / kgK)(1400K 688.32K) 715.24kJ / kg a) Net work:

Wnet Wout Win 715.24kJ / kg 301.34kJ / kg 413.9kJ / kg b) Heat rejected:

qout c p (T4 T1 ) 1.005kJ / kg(688.32K 290K) 400.31kJ / kg c) Thermal efficiency:

qin c p (T3 T2 ) 1.005kJ / kg(1400K 589.84K) 814.21kJ / kg

Wnet 413.9kJ / kg th 0.508 qin 814.21kJ / kg

3. (30 points) A four-cylinder, four-stroke internal combustion engine has a bore of 95.25 mm. and a stroke of 87.63 mm. The clearance volume is 17% of the cylinder volume at bottom dead center and the crankshaft rotates at 2600 RPM. The total volume of the cylinder is the volume of bore and stroke volume plus the clearance volume. The processes within each cylinder are modeled as an Otto cycle with a pressure of 1 atm and a temperature of 288 K at the beginning of compression. The maximum temperature in the cycle is 2888 K. Use the following constants in your analysis: k = 1.4 for air/fuel mixture (compression) and k = 1.285 for combustion products (expansion) Cv = 0.926 kJ/kg*K between steps 2 and 3, Cv = 0.825 kJ/kg*K between steps 4 and 1

(a) (4 points) Draw the P-v diagram; label Pressures, Temperatures, Qin, and Qout (b) (2 points) Calculate the mass of air at the beginning of the cycle (c) (12 points) Calculate the Pressure in kPa and Temperature in K at each step in the cycle (d) (6 points) Calculate the net Work per cycle in Joules (e) (3 points) Calculate the power developed by the engine in kW (f) (3 points) Calculate the thermal efficiency of this engine

Solution (a) See diagrams in Cengal pg 292-293.

d 2 0.09525m2 V V V h 0.17V 0.08763m 0.17V Total bore&stroke clearance total total 4 4 3 3 VTotal 0.000624m 0.17VTotal VTotal 0.000752m

N 3 101,000 2 0.000752m P1V1 m m 0.92g (b solution) RT 1 0.2870 J 288K g * K 1-2 Isentropic compression: k 1.4 v 0.000752m3 P P 1 101kPa P 1205kPa 2 1 3 2 v2 0.000128m k 1 1.41 P k 1205kPa 1.4 2 T2 T1 288K T2 585K P1 101kPa

2-3 Heat addition: T 2888K Q mCvT T 0.00092kg0.926 kJ 2888K 585K 3 in 3 2 kg * K

Qin 1.96kJ P V P V V T 2888K 2 2 3 3 2 3 P3 P2 1205kPa1 P3 5950kPa RT2 RT3 V3 T2 585K

3-4 Isentropic Expansion: k 1.285 v 0.000128m3 P P 3 5950kPa P 611kPa 4 3 3 4 v4 0.000752m k 1 1.2851 P k 611kPa 1.285 4 T4 T3 2888K T4 1743K P3 5950kPa

4-1 Heat rejection Q mCvT T 0.00092kg0.825kJ 288K 1743K out 1 4 kg * K

Qout 1.10kJ

Net work per cycle:

Wnet Qin Qout 1.96kJ 1.10kJ Wnet 856J

Power developed by the engine: 2600 rev RPM 1min min 1min Power # cylinders Wnet 4cylinders 856J Power 74.2kW 2 60sec 2 60sec Thermal efficiency:

Wnet 856J th th 43.6% Qin 1960J 4. (30 points) The conditions at the beginning of compression in an air-standard Diesel cycle are fixed by p1= 200 kPa, T1 = 380 K. The compression ratio is 20 and the heat addition per unit mass is 900 kJ/kg. Use k = 1.4 for air/fuel mixture (compression) and k = 1.34 for combustion products (expansion).

Hint: To determine T3, use the averaged temperature value between T3 and T2 to determine the temperature corresponding to a value for average Cp and iterate until you calculate values for average Cp and T3 that work in the equations. A first guess for the value of T3 will be between 1600 and 2000 K. Use three decimal places only for average Cp in kJ/kg*K and also round temperature values to the nearest value in four significant digits for this problem (i.e. No decimal places for temperatures). Table A-19 has values for air and the units for Cp should be J/kg *K.

(Total points noted in each section; must clearly show equations with values and units, drawings, assumptions, etc.) (a) (4 points) Draw the P-v diagram and label Pressures, Temperatures, Qin, and Qout (b) (14 points) Calculate the Pressure in kPa and Temperature in K at each step in the cycle (c) (4 points) Calculate the net Work per cycle in kJ/kg. (d) (4 points) Calculate the cutoff ratio (e) (4 points) Calculate the thermal efficiency of the cycle

Solution: (a) See pg 298 in Cengal for diagrams.

1-2 Isentropic compression k v 1 0.4 T2 T1 38020 T2 1259K v2 k v 2 1.4 P2 P1 200kPa20 P2 13300kPa v1

2-3 Heat addition q C T T 900 kJ C T 1259K in p 3 2 kg p 3

Choose T3 = 1983K, Calculate a Cp q C T T 900 kJ C 1983 1259K C 1.243 in p 3 2 kg p p

Check average temperature of T3 and T2 in Cengal Table A-19

T T 3 2 1621K TableA 19, Air C 1.243 Temp _ Guess _ OK 2 p Calculate cutoff ratio P V P V V T 1983K 2 2 3 3 3 3 Const _ P rc 1.575 RT2 RT3 V2 T2 1259K

3-4 Isentropic expansion k 1 0.34 v 1 T T 3 r 1983K 1.575 T 836K 4 3 c 4 v4 20 k 1.34 v 1 P P 3 r 13300kPa 1.575 P 442kPa 4 3 c 4 v4 20 q CvT T 0.764 kJ 380K 836K out 1 4 kg * K q 348kJ out kg

Net work per cycle: wnet qin qout 900kJ 348kJ wnet 552kJ

Thermal efficiency:

wnet 552kJ th th 61.3% qin 900kJ