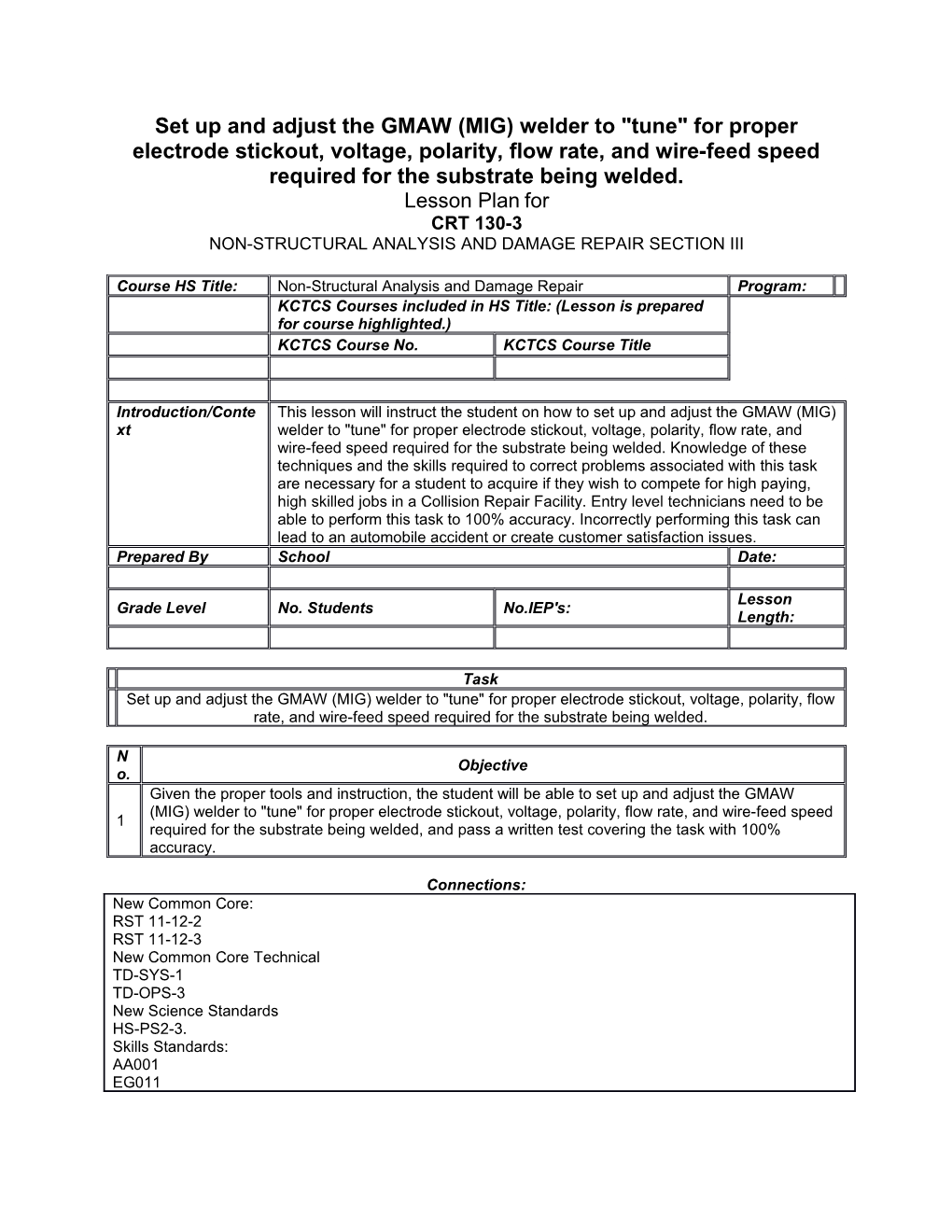

Set up and adjust the GMAW (MIG) welder to "tune" for proper electrode stickout, voltage, polarity, flow rate, and wire-feed speed required for the substrate being welded. Lesson Plan for CRT 130-3 NON-STRUCTURAL ANALYSIS AND DAMAGE REPAIR SECTION III

Course HS Title: Non-Structural Analysis and Damage Repair Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title

Introduction/Conte This lesson will instruct the student on how to set up and adjust the GMAW (MIG) xt welder to "tune" for proper electrode stickout, voltage, polarity, flow rate, and wire-feed speed required for the substrate being welded. Knowledge of these techniques and the skills required to correct problems associated with this task are necessary for a student to acquire if they wish to compete for high paying, high skilled jobs in a Collision Repair Facility. Entry level technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task can lead to an automobile accident or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Set up and adjust the GMAW (MIG) welder to "tune" for proper electrode stickout, voltage, polarity, flow rate, and wire-feed speed required for the substrate being welded.

N Objective o. Given the proper tools and instruction, the student will be able to set up and adjust the GMAW (MIG) welder to "tune" for proper electrode stickout, voltage, polarity, flow rate, and wire-feed speed 1 required for the substrate being welded, and pass a written test covering the task with 100% accuracy.

Connections: New Common Core: RST 11-12-2 RST 11-12-3 New Common Core Technical TD-SYS-1 TD-OPS-3 New Science Standards HS-PS2-3. Skills Standards: AA001 EG011 INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts

Textbooks and Workbooks Autho Editio Publishe Page Title/ISBN No. r n r s Variou ASE Test Prep Non Structural Analysis and Damage Repair Third Delmar 31 s

Equipment Quantity Item Source As Needed Welder Various

Content/Presentation/Demonstration Outline Tell students that good welding results depend on proper arc length. The length of the arc is determined by the arc voltage. Let them know that when the arc voltage is set properly, a continuous light hissing or cracking sound is emitted from the welding area. When the arc voltage is low, the arc length decreases, penetration is deep, and the bead is narrow and dome shaped. Tell them a sputtering sound and no are means that the voltage is too low. Instruct students that the tip-to-base distance is also an important factor in obtaining good welding results. Tell students that the standard MIG welding tip-to-base distance is approximately 1/4 to 5/8 inches (6.3 to 15.9 mm). Explain that if the tip-to-base distance is too long, the length of wire protruding from the end of the gun increases and becomes preheated, which increases the melting speed of the wire. Also, tell students that the shield gas effect will be reduced if the tip-to-base distance is too long. If the tip-to-base distance is too short, explain that it becomes difficult to see the progress of the weld because it will be hidden behind the tip of the gun. Teach students that the two welding methods used are the forward (or forehand) and the reverse (or backhand) methods. With the forward method, the penetration is shallow and the bead is flat. With the reverse method, the penetration is deep and a large amount of metal is deposited. Let them know that the gun angle for both should be 10 degrees. Inform students that precise gas flow is essential to a good weld. If the volume of gas is too high, it will flow in eddies (ripples in the weld caused by gas flow pushing the weld puddle) and reduce the shield effect. If there is not enough gas, the shield effect will be reduced. Tell students that adjustment is made in accordance with the distance between the nozzle and the base metal, the welding current, the welding speed, and the welding environment. Let them know that the standard flow volume is approximately 1 3/8 to 1 1/2 cubic inches (0.022 to 0.024 liters) per minute or 15 to 25 cubic feet (420 to 700 cubic liters) per hour. Tell students that if they weld at a rapid pace, the penetration depth and bead width decreases, and the bead is dome shaped. If the speed is increased even faster, undercutting (in which the weld surface is lower than the base metal) can occur. Welding at too slow a speed can cause bum-through holes. Let them know that ordinarily, welding speed is determined by base metal thickness and/or the voltage of the welding machine. Instruct students that an even, high-pitched buzzing sound indicates the right wire-to-heat ratio producing a temperature of approximately 9,000°F (4,982°C). Tell them that visual signs of the right setting occur when a steady reflected light starts to fade in intensity as the arc is shortened and wire speed is increased. Let them know that if the wire speed is too low, a hiss and a plop sound will be heard as the wire melts away from the puddle and deposits the molten glob back. Explain to students that the visual result will be a much brighter reflected light. Too much wire speed will choke the arc; more wire is being deposited than the heat and puddle can absorb. Tell them the result is spitting and sputtering as the wire melts into tiny balls of molten metal that fly away from the weld. Let them know that the visual signal is a strobe light arc effect.

Applications/Practice 1 Refer to content

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)