Process: Zero Discharge Dairy Farm Waste Treatment

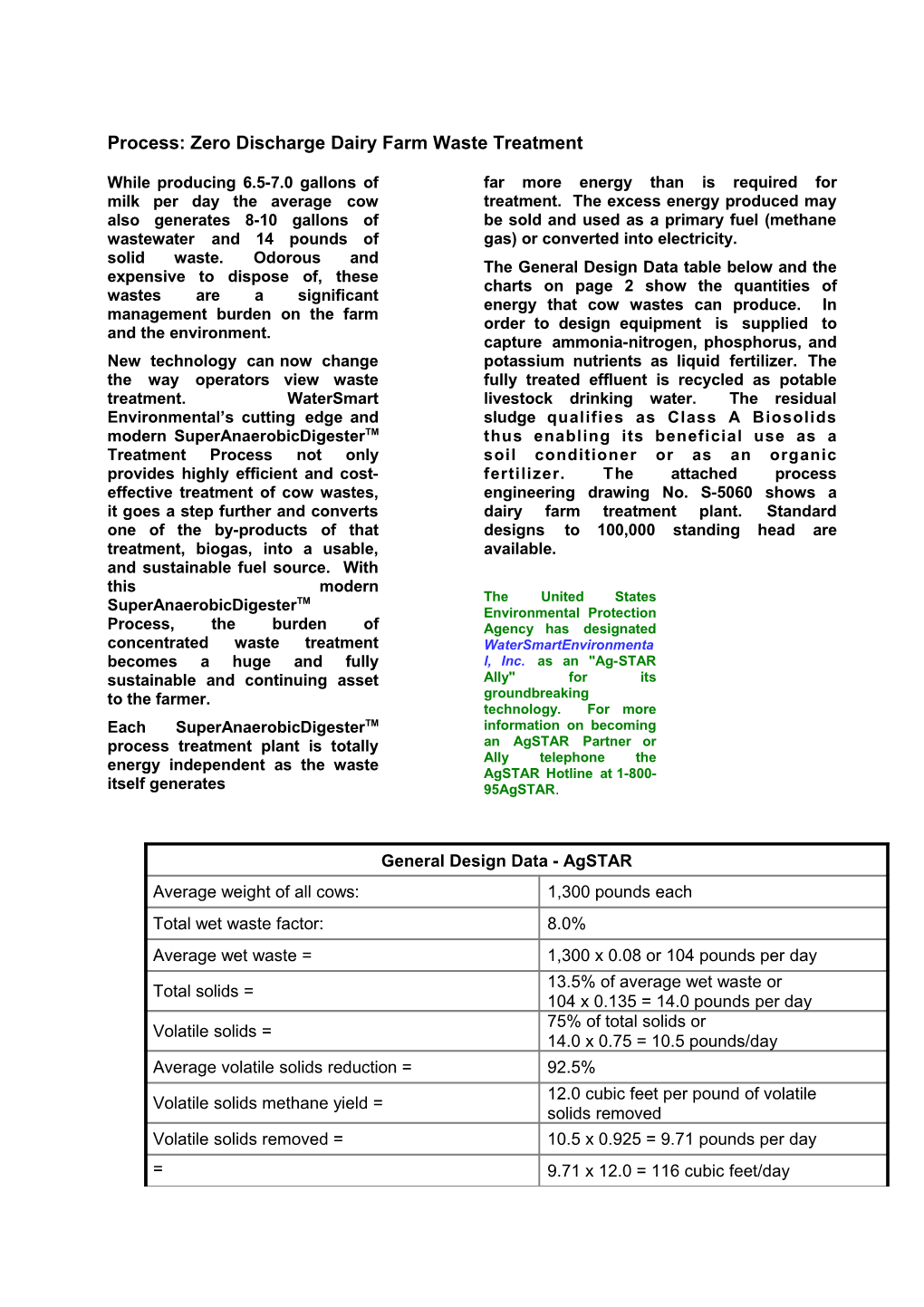

While producing 6.5-7.0 gallons of far more energy than is required for milk per day the average cow treatment. The excess energy produced may also generates 8-10 gallons of be sold and used as a primary fuel (methane wastewater and 14 pounds of gas) or converted into electricity. solid waste. Odorous and The General Design Data table below and the expensive to dispose of, these charts on page 2 show the quantities of wastes are a significant energy that cow wastes can produce. In management burden on the farm order to design equipment is supplied to and the environment. capture ammonia-nitrogen, phosphorus, and New technology can now change potassium nutrients as liquid fertilizer. The the way operators view waste fully treated effluent is recycled as potable treatment. WaterSmart livestock drinking water. The residual Environmental’s cutting edge and sludge qualifies as Class A Biosolids modern SuperAnaerobicDigesterTM thus enabling its beneficial use as a Treatment Process not only soil conditioner or as an organic provides highly efficient and cost- fertilizer. The attached process effective treatment of cow wastes, engineering drawing No. S-5060 shows a it goes a step further and converts dairy farm treatment plant. Standard one of the by-products of that designs to 100,000 standing head are treatment, biogas, into a usable, available. and sustainable fuel source. With this modern TM The United States SuperAnaerobicDigester Environmental Protection Process, the burden of Agency has designated concentrated waste treatment WaterSmartEnvironmenta becomes a huge and fully l, Inc. as an "Ag-STAR sustainable and continuing asset Ally" for its to the farmer. groundbreaking technology. For more Each SuperAnaerobicDigesterTM information on becoming process treatment plant is totally an AgSTAR Partner or energy independent as the waste Ally telephone the AgSTAR Hotline at 1-800- itself generates 95AgSTAR.

General Design Data - AgSTAR Average weight of all cows: 1,300 pounds each Total wet waste factor: 8.0% Average wet waste = 1,300 x 0.08 or 104 pounds per day 13.5% of average wet waste or Total solids = 104 x 0.135 = 14.0 pounds per day 75% of total solids or Volatile solids = 14.0 x 0.75 = 10.5 pounds/day Average volatile solids reduction = 92.5% 12.0 cubic feet per pound of volatile Volatile solids methane yield = solids removed Volatile solids removed = 10.5 x 0.925 = 9.71 pounds per day = 9.71 x 12.0 = 116 cubic feet/day Approximate methane conversion factor is: 12 CFH = 1 kW Waste-generated biogas per standing head measured in cubic feet per hour (CFH) and cubic meters per hour (m3/h). The appropriate kilowatt sized gas generator is also shown

Standing Head 100 200 300 400 500 600 700 800 900 1,000 CFH 483 967 1,450 1,934 2,417 2,900 3,383 3,868 4,350 4,833 m3/h 13.7 27.4 41.1 54.8 68.5 82.2 95.9 110 123 137 kW 40 80 120 160 200 240 280 320 360 400

Standing Head 1,000 2,000 3,000 4,000 5,000 6,000 7,000 8,000 9,000 10,000 CFH 4,833 9,666 14,500 19,332 24,166 29,000 33,832 38,664 43,498 48,332 m3/h 137 274 411 826 685 822 1,237 1,652 1,511 1,370 kW 400 800 1,200 1,600 2,000 2,400 2,800 3,200 3,600 4,000

Standing Head 10,000 20,000 30,000 40,000 50,000 60,000 70,000 80,000 90,000 100,000 CFH 48,332 96,664 145,000 193,000 242,000 290,000 338,000 386,000 435,000 484,000 m3/h 1,370 2,740 4,110 5,480 6,850 8,220 9,590 10,960 12,330 13,700 kW 4,000 8,000 12,000 16,000 20,000 24,000 28,000 32,000 36,000 40,000 Dairy Waste-To-Energy …no land disposal of manure …zero liquid discharges Made possible by the ™ SuperAnaerobicDigester Optimized Anaerobic Treatment Process

© 2001 WaterSmart Environmental, Inc. No Lagoons.

All liquid and solid wastes are continuously treated, not stored. Existing lagoons may be decommissioned. Animal deads are processed and added to the waste feedstock rather than rendered. Eliminates all potential for surface runoff and groundwater pollution. No Land Disposal of Solids or Liquid Manure. Dairy waste solids and liquids are continuously treated by anaerobic digestion and converted into methane gas, carbon dioxide gas, organic fertilizer, and liquid fertilizer concentrate. Animal deads are ground and added to the digester as organic wastes. No Liquid Discharges.

The digester effluent is highly purified by reverse osmosis (RO) treatment. The RO concentrate contains ammonia nitrogen orthophosphates, and potassium salts, the main components of liquid fertilizer. The RO permeate is continuously recycled for livestock drinking water. Total Treatment Design. Solids (Digestate) Composition. Grit and sand. Insoluble Sulfides of Cadmium, Calcium, Copper, Iron, Lead, Manganese, Trivalent Chromium, and Zinc. Approximately 1-1-1 NPK (Nitrogen, Phosphorus, and Potassium) Qualifies as Class “A” Biosolids in compliance with 40 CFR Part 503 Also Qualifies as Organic Fertilizer Solids Management.

May be used as livestock bedding material since it is pathogen free. May be sold to the marketplace as an organic fertilizer commodity. May be sold to the marketplace as a soil conditioner or soil amendment. Liquid Streams.

Liquid fertilizer concentrate. Reverse osmosis permeate. Liquid Fertilizer Concentrate.

Contains about 20-10-10 NPK in a concentrated water solution. Contains trace amounts of aluminum, magnesium, and sodium salts Reverse Osmosis Permeate. Total dissolved solids < 50 mg/L Total coliform count < 1MPN/100 mL BOD < 1 mg/L COD < 1 mg/L TOC < 1 mg/L TSS < 1 mg/L NPK < 10 mg/L Liquids Management.

Liquid fertilizer concentrate may be directly used by the farmer for routine crop nutrient requirements. Liquid fertilizer may be sold to the marketplace as a commodity. Reverse osmosis permeate water is continuously recycled as livestock drinking water. Other Co-Products.

Methane gas. Carbon dioxide gas. Co-Product Methane.

Is compressed, dried, and stored at 300 psig for site use and for generation of electricity. Compressed methane may also be sold as CMG (compressed methane gas) or LMG (liquefied methane gas). Generated electricity may be used at with excess sold to utility grid. Co-Product Management.

No release of methane gas to the environment. No release of carbon dioxide gas to the environment. No gas releases accomplish a 500%+ reduction in greenhouse gas effect. Complete Odor Control.

No liquid or solid manures are ever land applied to create odors. Odors within enclosed livestock barns are controlled by continuous use as power plant combustion air thereby achieving complete thermal oxidation. Odors are therefore destroyed rather than discharged to the environment. Co-Product Carbon Dioxide.

Is compressed, dried, purified, and liquefied for sale to the marketplace as a commodity. Meets food and medical grade quality. The SuperAnaerobicDigester™ Process Is the only process that combines: Two-phase Anaerobic Digestion Thermophilic Bacteria Staged Phase Treatment Fixed Growth Media Flow Recirculation pH and Temperature Control Essential Nutrient Addition Bacteria Can Produce Fuel From Liquid & Solid Wastes.

Solid waste landfills biologically generate methane gas (called biogas) as clear evidence of the ability of bacteria to produce fuel. Biogas is a mixture of carbon dioxide and methane gas. It has a heating value of about 25,000 kJ per cubic meter. Biogas can be used as a primary fuel or to generate electricity. Wastewater Treatment Plants Use Bacteria.

Almost all wastewater treatment plants use bacteria to treat the water. Aerobic plants use aeration. They consume about 8,000 kJ per kg COD (Chemical Oxygen Demand) removed. WaterSmart’s OAT™ anaerobic plant generates about 22,000 kJ/kg COD for an energy improvement of about 30,000 kJ/kg COD. Wastes That Can Be Converted Into Biogas.

Municipal Palm Oil Mills Wastewater Landfill Leachate Chemical Manufacturing Pulp & Paper Mills Sugar Mills Breweries & Agricultural Solid Distilleries Wastes Fish & Cardboard & Sawdust Food Ethanol Plants Processi Rubber Plantations ng ...More Eligible Wastes.

Animal Feed Lot Wastes Dairy & Cheese Production Fruit & Vegetable Canning Pharmaceutical Wastes Rendering Plants Textile Manufacturing Municipal & Industrial Digester Sludge Food and Green Wastes Municipal Solid Wastes A Renewable And Alternative Energy Source. These many wastes are generated each and every day in the normal course of living. The routine treatment or disposal of wastes is tremendously expensive. ™ The SuperAnaerobicDigester process, however, makes their treatment or disposal profitable, an extremely pleasant surprise. Excess Energy Produced.

The SuperAnaerobicDigesterTM process uses some of the methane it generates to heat the wastewater being treated. The excess methane can be sold, used to operate pumps, or generate electricity. The excess green power electricity can be used by the treatment plant, sold to the local electric utility, or even to a distant business or city through the Internet. Positive Return On Investment. When one generates a profit from the treatment of wastes, a positive return on investment (ROI) always results. Rather than a burden on society, wastes may now be viewed as an asset--an incredible reversal of common perception. Wastewater treatment plants of the anaerobic digester design can now pay for themselves! Energy Costs. Wastewater treatment is very expensive, particularly because of energy costs which increase at 3-5% every year. A typical biological wastewater treatment plant uses about 8,000 kJ per kg COD (Chemical Oxygen Demand) removed. WaterSmart’s SuperAnaerobicDigesterTM process can produce up to 22,000 kJ/kg COD removed, for an energy improvement of about 30,000 kJ per kg COD. Capital Equipment Costs.

Are also very expensive, on the order of US$2K+ for every kg of COD treatment capacity. If ammonia, nitrate, phosphorus, or heavy metal removals are required, the associated costs are much higher. WaterSmart’s Anaerobic Treatment Plant costs about half as much as other anaerobic systems treating the same amount of COD or Volatile Solids. Environmentally Friendly And Sensible. Korea’s Sudokwon Landfill, the world’s largest, has the motto: “Don’t Waste Wastes.” We share that view and believe wastes should be converted into something useful, like fuel or electricity, if it can be done so safely and economically. In so doing, waste volumes are greatly reduced to better manage the environment for ourselves and the next generation. Odors? Absolutely None!

All treatment is carried out in closed vessels Hydrogen Sulfide is removed from produced biogas. All gasses are captured and used or recycled. None escape. Environmental Damage? Absolutely None! No emissions to atmosphere. Heavy metals removed as insoluble sulfides. Organic constituents removed to innocuous levels. Effluent contains nutrients which are beneficially recycled. Beneficial Co-Products

In addition to methane gas, the digester process generates other useful and profitable co-products. Carbon Dioxide Organic Fertilizer Liquid Fertilizer Concentrate Reverse Osmosis Permeate Water Greenhouse Gasses

A methane powered generator or gas turbine will discharge EPA permissible amounts of carbon dioxide when producing electricity. If a fuel cell is used to make electricity, no carbon dioxide is discharged. No methane is ever discharged to the environment. Noise…

Practically none! The loudest component is a biogas powered generator or turbine -- similar to a truck engine. Noise producing equipment can easily be enclosed for noise attenuation. Sludge

0.01 pounds of solids produced for every pound of BOD removed—about 25% that of competitive anaerobic treatment plants! The SuperAnaerobicDigesterTM process sludge qualifies as Class “A” Biosolids that can be sold as fully certified organic fertilizer. Single Vessel Design.

Carbon Dioxide outlet Methane outlet

85-95% CH 4 97% CO 5-15% CO 2 2 Vertical circular insulated 0-1% H S Liquid outlet 0-3% + 2 process vessel with dome cover N H S 2 2 Static water level Methanogenic stage isolation wall Acidogenic stage isolation wall

Phase partition wall 1st stage acidogenic digester 2nd stage acidogenic digester

Headworks.

After trash removal: Grind or comminute the raw wastewater. No primary treatment required. Biosolids may be ground and added. Organic wastes may also be added. Liquid organic wastes may also be added. Green Wastes may also be added. Food wastes may also be added. Sophisticated Design But Easy To Operate.

Automatic controls simplify routine plant operations. Close process control translates into a high degree of treatment efficiency. Minimal plant operator skill required. Digester Upgrades Available.

Existing anaerobic digesters may usually be upgraded to the digester process thus saving project site construction and piping costs. A complete upgrade to the digester process can increase the digester capacity 10 times. Beneficial use or sale of the produced methane, electricity, Class A biosolids, reverse osmosis permeate water, and carbon dioxide makes the upgrade a positive ROI. Summary. Wastes can be beneficially converted into fuel or electricity. An efficient anaerobic treatment process results in a positive return on investment. The SuperAnaerobicDigester™ process is the most efficient anaerobic treatment available. SuperAnaerobicDigester™ plants are smaller, less expensive, do not smell, and generate a profit. Reverse Osmosis permeate can be continuously recycled for livestock drinking water For Project Feasibility Studies and Proposals

Contact: WaterSmart Environmental, Inc. POC: Chuck Steiner @ 913-428-7520 Fax: 913-428-7520 email: [email protected] Website: www.watersmart.com