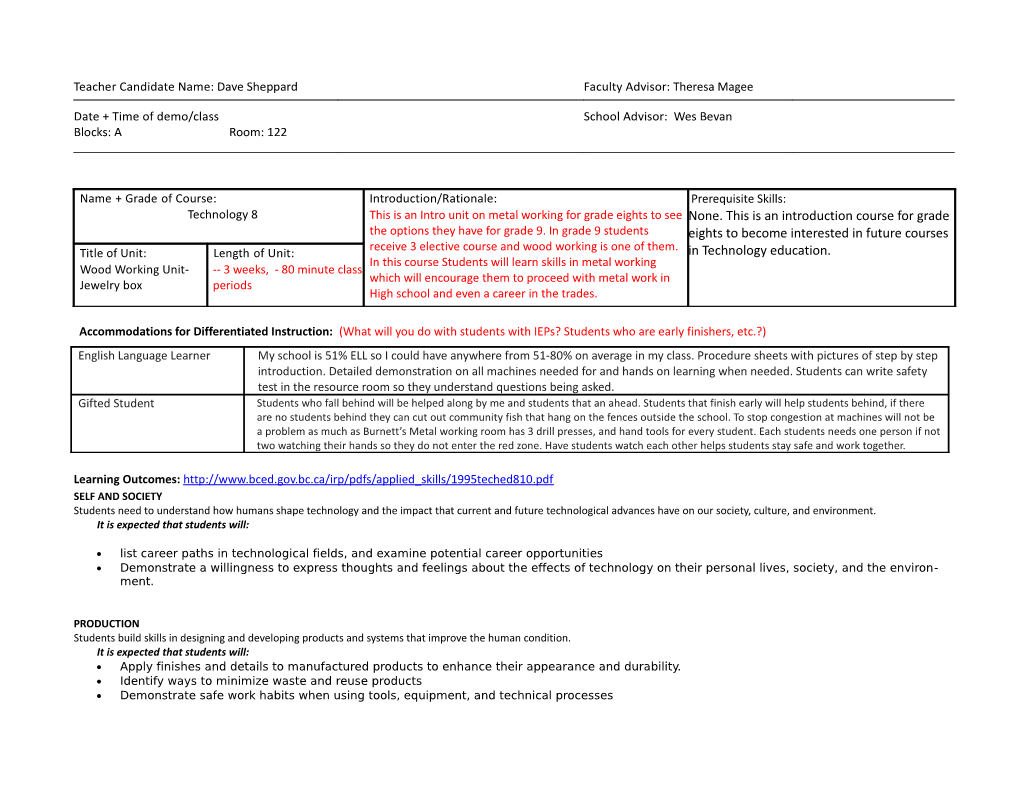

Teacher Candidate Name: Dave Sheppard Faculty Advisor: Theresa Magee

Date + Time of demo/class School Advisor: Wes Bevan Blocks: A Room: 122

Name + Grade of Course: Introduction/Rationale: Prerequisite Skills: Technology 8 This is an Intro unit on metal working for grade eights to see None. This is an introduction course for grade the options they have for grade 9. In grade 9 students eights to become interested in future courses receive 3 elective course and wood working is one of them. Title of Unit: Length of Unit: in Technology education. In this course Students will learn skills in metal working Wood Working Unit- -- 3 weeks, - 80 minute class which will encourage them to proceed with metal work in Jewelry box periods High school and even a career in the trades.

Accommodations for Differentiated Instruction: (What will you do with students with IEPs? Students who are early finishers, etc.?) English Language Learner My school is 51% ELL so I could have anywhere from 51-80% on average in my class. Procedure sheets with pictures of step by step introduction. Detailed demonstration on all machines needed for and hands on learning when needed. Students can write safety test in the resource room so they understand questions being asked. Gifted Student Students who fall behind will be helped along by me and students that an ahead. Students that finish early will help students behind, if there are no students behind they can cut out community fish that hang on the fences outside the school. To stop congestion at machines will not be a problem as much as Burnett’s Metal working room has 3 drill presses, and hand tools for every student. Each students needs one person if not two watching their hands so they do not enter the red zone. Have students watch each other helps students stay safe and work together.

Learning Outcomes: http://www.bced.gov.bc.ca/irp/pdfs/applied_skills/1995teched810.pdf SELF AND SOCIETY Students need to understand how humans shape technology and the impact that current and future technological advances have on our society, culture, and environment. It is expected that students will:

list career paths in technological fields, and examine potential career opportunities Demonstrate a willingness to express thoughts and feelings about the effects of technology on their personal lives, society, and the environ- ment.

PRODUCTION Students build skills in designing and developing products and systems that improve the human condition. It is expected that students will: Apply finishes and details to manufactured products to enhance their appearance and durability. Identify ways to minimize waste and reuse products Demonstrate safe work habits when using tools, equipment, and technical processes Describe and use the process of product design Identify and classify the properties of materials used to manufacture products Communication At home and in the workplace, students will need to use technology in the processing and sharing of information, and communicate ideas using lan- guage, graphics, and technology.. It is expected that students will: Produce initial concept sketches and final drawings using a design process. Solve problems that come up during the design process by using various information sources.

Length of Unit: February 7 to March 25-27, 2015

Side Project for early finishers: Community Fish or finish metal project if not already done.

◄ January ~ February 2015 ~ March ► Sun Mon Tue Wed Thu Fri Sat

11 2 Start Practicum 3 5 6 7 8 Start of Metal Unit Introduction to Tech 8 8 9 Family Day 10 11 12 13 14 Safety demonstration Power tools- Drill Press Construction Starts Construction Starts

15 16 17 18 19 20 21 Drill press safety test Grinder safety test Slots and Counter sinking Base Power tools- Grinder 22 23 24 25 26 27 28 Joining Base to the Frame Joining Base to the Painting and completion Painting and completion end of metal unit Frame LESSON TOPIC SPECIFIC LESSON TEACHING STUDENT MATERIALS & ASSESSMENT OBJECTIVES (SWBAT) METHODS + ACTIVITIES RESOURCES STRATEGIES + ACTIVITIES CRITERIA Introduction to Tech 8 Students will learn about the -lecture -ice breaker - Course outline -Entrance slip on what they (1 day) course and what they will be do- -ice breakers -Students will - Folders would like to learn in unit ing during the semester. -demo learn expectations. - Students will be given course -entrance slip on outline with all expectations that what they would they should I’ll be looking for. like to learn in the List career paths in technological unit. fields, and examine potential ca- -equipment review reer bv opportunities. Hand tool safety. by drawing the shop and where all the tools are.

Safety demonstration Students will learn how to use -Demo •The students will - Safety sheets -The students will go draw (1 day) the general shop safety. -pair work go draw all the - Drawing sheet. all the tools in a work sheet Introduction hand tools such as tools in a work - -Test will be given the Hack saw, files, center punch, sheet following class lay-out punch, Scribe, hammers, • scale/ ruler and squares. Students They will also will learn shop Safety. find the home for all the tools •Students will review for test the following class on shop safety. Power tools- Drill Press Students will learn how to use -Review •Students can - Test papers -The students will go draw (1 day) the drill press. Students will be -Demo finish drawings at - Safety test for drill press all the tools in a work sheet introduced to project and Metal home if they - -7 working unit. cannot finish it in class time •Students will review sheet they fill out for the test the following day on shop safety and hand tools. Construction Starts Students will learn how to hack -Review •The students will - Hack saw -participation mark (2 Days) saw, files, hammer, and alphabet -Demo use a hack saw to - 1” band iron punches. Students will start -Individual cut out a 13” piece - Square construction on Picture frame of 1” band iron. - Files rough and smooth project. •Students will use - Scale a square and file to - Alphabet letter punches square one side of the band iron. •Students will clean the faces and edges of band iron. •Students will re measure the band iron and will cut there piece to be exactly 10” •Students will punch initials into project pieces •If students have time they will use a file to square off other side to make piece 10” long exactly. Drill press safety test Students will be examined on -Review -Students will be - Test paper • Students are given a (1 day) drill press safety. -Individual examined on drill - Pens participation mark -Test press safety. - Hand Tools • Test will be given -Continue work on - Drill press during students must get 80% project to work on drill press Power tools- Grinder Students will learn how to use -Review •Students will - Grinder Students are given a (1 Day) the Grinder. Students will work -Demo layout punch for - Grinder info sheet participation mark on project. -Individual use on the drill - press at 1 ½, 1 3/8, and 2 5/8 •Students will drill out ¼ inch holes on the mark they made before. •Students will layout line in between the holes so they know where to bend. •Students will then grind the ends of the band iron to the perfect radius of work piece. Grinder Test Students will be examined on -Review Students will be - Test paper Test will be given during (1 day) grinder safety. -Individual examined on - Pens students must get 80% to grinder. - Hand Tools work on grinder -Continue work on - Grinder project

Slots and Counter sinking Student will learn how use a -Review -Student will make - Hack saw Students are given a (2 days) hack saw and make a slot into -Demo slot into their own - Picture frame participation mark their picture frame. Then will -Individual work piece. - Drill press clean out slot with a file. -Continue work on - File Students will learn to counter project sink on drill press. -center punch marks ½ inch form each side of center -dill out 1/8” holes -countersink holes on side opposite of bends.

Base Students will create the base for -Review -students will hack - Vice Students are given a (1 day) their metal picture frame. -Demo saw another piece - Hack saw participation mark -Individual of band iron off at - Square 2 ¾ inch. - Drill press -then square the - File piece the edges. -then they will bend the band iron at ½ inch to their desired degree. Joining Base to the Frame Students will use rivets to -Review -line up center - Vice Students are given a (1-2 days) connect there picture frame to -Demo marks of each - Hack saw participation mark the base. -Individual piece and tape - Square them together - Drill press using double sided - File tape. - Rivets Drill holes in base - Rivet gun to match the holes in the frame. -Rivet the 2 pieces together being sure to keep the countersunk side out -File the rivet flat inside - make 3rd and 4th bend

Painting and completion Students will learn how to use -Review Students will - Vice -Students are given a (1-2 days) the powder coater in small -Demo powder coat there - Hack saw participation mark groups because of limited space. -Individual picture frames. - Square -Students will be given a - Drill press mark for their final product. - File - Powder coater - Oven

Evaluation: Unit is worth 33% of overall mark in Technology 8: Tech 8 is 3 Units long including wood working, metal working, and electronics.

Participation mark- 10% Safety Test- 5% Overall Project- 18%

Key Vocabulary words:

Rubrics: See handout