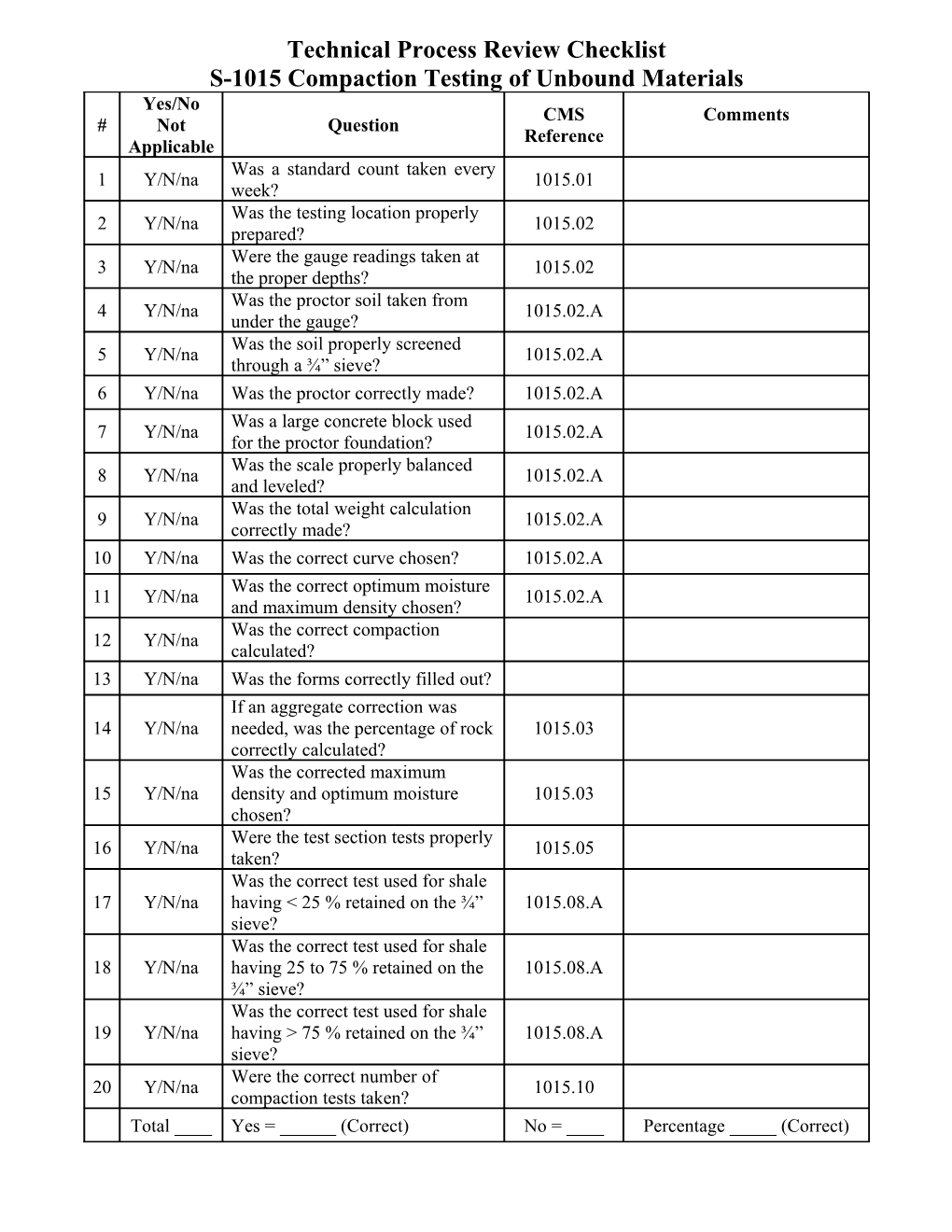

Technical Process Review Checklist S-1015 Compaction Testing of Unbound Materials Yes/No CMS Comments # Not Question Reference Applicable Was a standard count taken every 1 Y/N/na 1015.01 week? Was the testing location properly 2 Y/N/na 1015.02 prepared? Were the gauge readings taken at 3 Y/N/na 1015.02 the proper depths? Was the proctor soil taken from 4 Y/N/na 1015.02.A under the gauge? Was the soil properly screened 5 Y/N/na 1015.02.A through a ¾” sieve? 6 Y/N/na Was the proctor correctly made? 1015.02.A Was a large concrete block used 7 Y/N/na 1015.02.A for the proctor foundation? Was the scale properly balanced 8 Y/N/na 1015.02.A and leveled? Was the total weight calculation 9 Y/N/na 1015.02.A correctly made? 10 Y/N/na Was the correct curve chosen? 1015.02.A Was the correct optimum moisture 11 Y/N/na 1015.02.A and maximum density chosen? Was the correct compaction 12 Y/N/na calculated? 13 Y/N/na Was the forms correctly filled out? If an aggregate correction was 14 Y/N/na needed, was the percentage of rock 1015.03 correctly calculated? Was the corrected maximum 15 Y/N/na density and optimum moisture 1015.03 chosen? Were the test section tests properly 16 Y/N/na 1015.05 taken? Was the correct test used for shale 17 Y/N/na having < 25 % retained on the ¾” 1015.08.A sieve? Was the correct test used for shale 18 Y/N/na having 25 to 75 % retained on the 1015.08.A ¾” sieve? Was the correct test used for shale 19 Y/N/na having > 75 % retained on the ¾” 1015.08.A sieve? Were the correct number of 20 Y/N/na 1015.10 compaction tests taken? Total ____ Yes = ______(Correct) No = ____ Percentage _____ (Correct)

Technical Process Review Checklist

Total Page:16

File Type:pdf, Size:1020Kb

Recommended publications