PETROFLEX NBR 3300 DHP Series TECHNICAL DATA

PRODUCT DESCRIPTION PETROFLEX NBR 3300 DHP Series Elastomers are products series presents a particularly high level of quality and butadiene-acrylonitrile copolymers with medium bound properties, exibiting better processing/mixing characteristics acrylonitrile content (33%) produced by cold emulsion and reduced mold fouling than conventional nitrile rubbers. polymerization under carefully controlled temperature. These PETROFLEX NBR 3300 DHP Series Elastomers are employed in oil and solvents chemical resistance goods.

TYPICAL APPLICATIONS PETROFLEX NBR 3300 DHP Series Elastomers is recommended for all kind of techincal goods including gaskets specially recommended for cellular hoses and tubes, and and retainers, seals (static seals, pipeline seals), “O” rings rubber formulations with great amount of fillers. Is also (shaft seals, grooved rings and V-type seals) etc that demands better processing/mixing characteristics and properties.

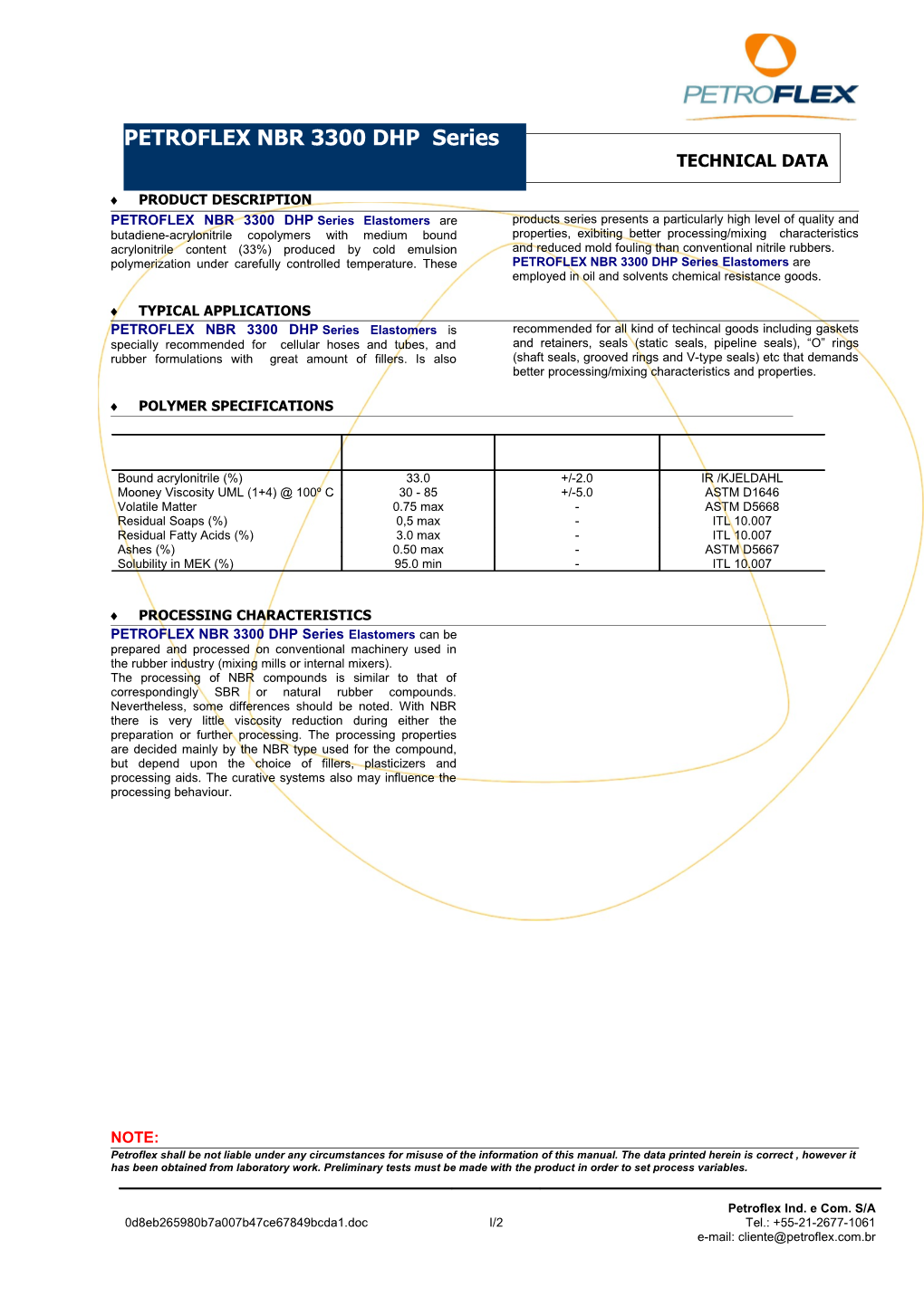

POLYMER SPECIFICATIONS

PETROFLEX NBR PROPERTIES LIMITS METHOD 3300 DHP series Bound acrylonitrile (%) 33.0 +/-2.0 IR /KJELDAHL Mooney Viscosity UML (1+4) @ 100º C 30 - 85 +/-5.0 ASTM D1646 Volatile Matter 0.75 max - ASTM D5668 Residual Soaps (%) 0,5 max - ITL 10.007 Residual Fatty Acids (%) 3.0 max - ITL 10.007 Ashes (%) 0.50 max - ASTM D5667 Solubility in MEK (%) 95.0 min - ITL 10.007

PROCESSING CHARACTERISTICS PETROFLEX NBR 3300 DHP Series Elastomers can be prepared and processed on conventional machinery used in the rubber industry (mixing mills or internal mixers). The processing of NBR compounds is similar to that of correspondingly SBR or natural rubber compounds. Nevertheless, some differences should be noted. With NBR there is very little viscosity reduction during either the preparation or further processing. The processing properties are decided mainly by the NBR type used for the compound, but depend upon the choice of fillers, plasticizers and processing aids. The curative systems also may influence the processing behaviour.

NOTE: Petroflex shall be not liable under any circumstances for misuse of the information of this manual. The data printed herein is correct , however it has been obtained from laboratory work. Preliminary tests must be made with the product in order to set process variables.

Petroflex Ind. e Com. S/A 0d8eb265980b7a007b47ce67849bcda1.doc I/2 Tel.: +55-21-2677-1061 e-mail: [email protected] PETROFLEX NBR 3300 DHP Series TECHNICAL DATA

PACKAGING AND STORAGE PETROFLEX NBR 3300 DHP Series Elastomers are should be taken to store nitrile elastomers in a cool, dry place, supplied in bale form in cardboard boxes with an internal layer away from direct light and sources of heat such as steam protection of silicone or in wood boxes with an internal pipes, boilers and under temperatures not above 104ºF (40ºC) polyethylene bag. Each box contains 36 bales of 35 kg. Care to maintain quality.

HANDLING AND SAFETY PETROFLEX NBR 3300 DHP Series Elastomers are not dangerous when processed in accordance with the product´s MSDS (Material Safety Data Sheet).

NOTE: Petroflex shall be not liable under any circumstances for misuse of the information of this manual. The data printed herein is correct , however it has been obtained from laboratory work. Preliminary tests must be made with the product in order to set process variables.

Petroflex Ind. e Com. S/A 0d8eb265980b7a007b47ce67849bcda1.doc II/2 Tel.: +55-21-2677-1061 e-mail: [email protected]