HAND BRAKE

Operation Manual

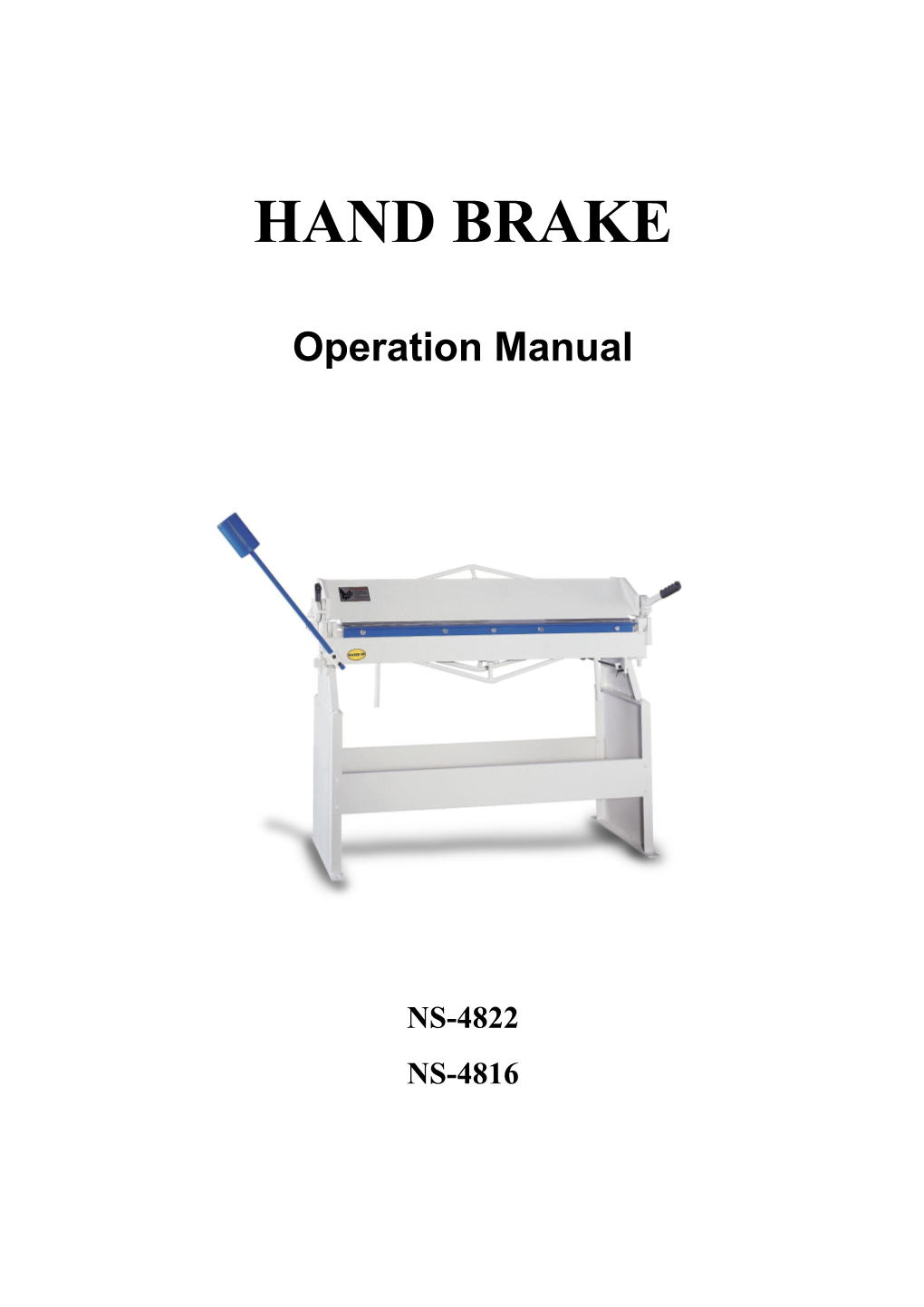

NS-4822 NS-4816 INSTRUCTIONS HAND BRAKE (Bench Type)

Don’t exceed rated capacity on this Brake. This Brake has been tested to bend 16 gauge (1.6mm) mild steel at the factory. An adjustment of 1/8” is provided in the position of the beam for metal thickness and radius of bend, this is controlled by eccentric pins for locking set screws. There should be clearance of at least 1 1/2 to 2 times thickness of material between the apron and edge of beam, when the apron is at the 90-degree position. The work is clamped between the bed and the tips of the Fingers by means of Eccentric Levers. With all Fingers in place, the Box & Pan Brake operates the same way as the plain Hand Brake. To make a bend, raise the apron handles to the desired angle, forcing the clamped work to bend around the tips of the fingers. In making a box or pan, the sides are bent up first. To bend the ends, group the fingers to a total width equal to the end of the box, leaving a space each side of this group by omitting a Finger. Clamp the end of the box under the grouped Fingers. When the Apron is raised to bend up the end, the sides already formed will pass to each side of the Fingers, avoiding interference. Clamping pressure is controlled by nuts, which are on the lower end of the toggle bolt. This pressure should be adjusted with a small piece of the material to be bent clamped in each end of the machine. Adjust the nuts so that the levers pull against the stops with an equal effort. Excessive clamping pressure is not required. Use only enough to hold the material firmly in the brake. These Brakes are not intended for bending rods. Bending rods will cause damage to the edge of the apron. Never use any material over 16 gauge mild steel. Lubricate the moving parts of the machine with light grease or heavy oil. Lasting accuracy depends on proper lubrication. CAUTION: THIS MACHINE MAY BE DANGEROUS IF NOT USED PROPERLY. Part Drawing/Part List – Hand Brake

No. Part Name No. Part Name 900. Holddown ass’y 54. Hex. Nut, toggle adjust 902. Base ass’y 55. Swivel pin 903. Apron ass’y 56. Nut, brace rod 40. Locknut 57. Screw, finger clamp 41. Flat washer 58. Fingers 42. Clamp handle R. H. 64. Screw bolt 43. Clamp handle L. H. 67. C clip 45. Handgrip, plastic 68. Balance bob ass’y 47. Toggle ass’y R. H. 69. Bending adj. Rod ass’y 48. Toggle ass’y L. H. 70. Pipe 49. Retainer ring 71. Screw, flat head 50. Bushing, Ecc. Pin 72. Blade, brake 51. Screw bolt 73. Ang. Brake 52. Set screw 74. Hex. Screw 53. Hinge pin, brass 75. Step bracket L. & R.