S U P P L I E R Q M S S U R V E Y Cop yr ig ht © 201 2 Mid -Co nt inent Engi ne er ing, Inc . All R ights R ese rved 405-35th Avenue NE Minneapolis MN 55418 Phone: 612.781.0260 Fax: 612.706.4364 www.mid-continent.com Important: The completion and submission of this QMS Survey to Mid-Continent Engineering shall be a certification by

the supplier that the information provided herein accurately represents the organization’s quality management system.

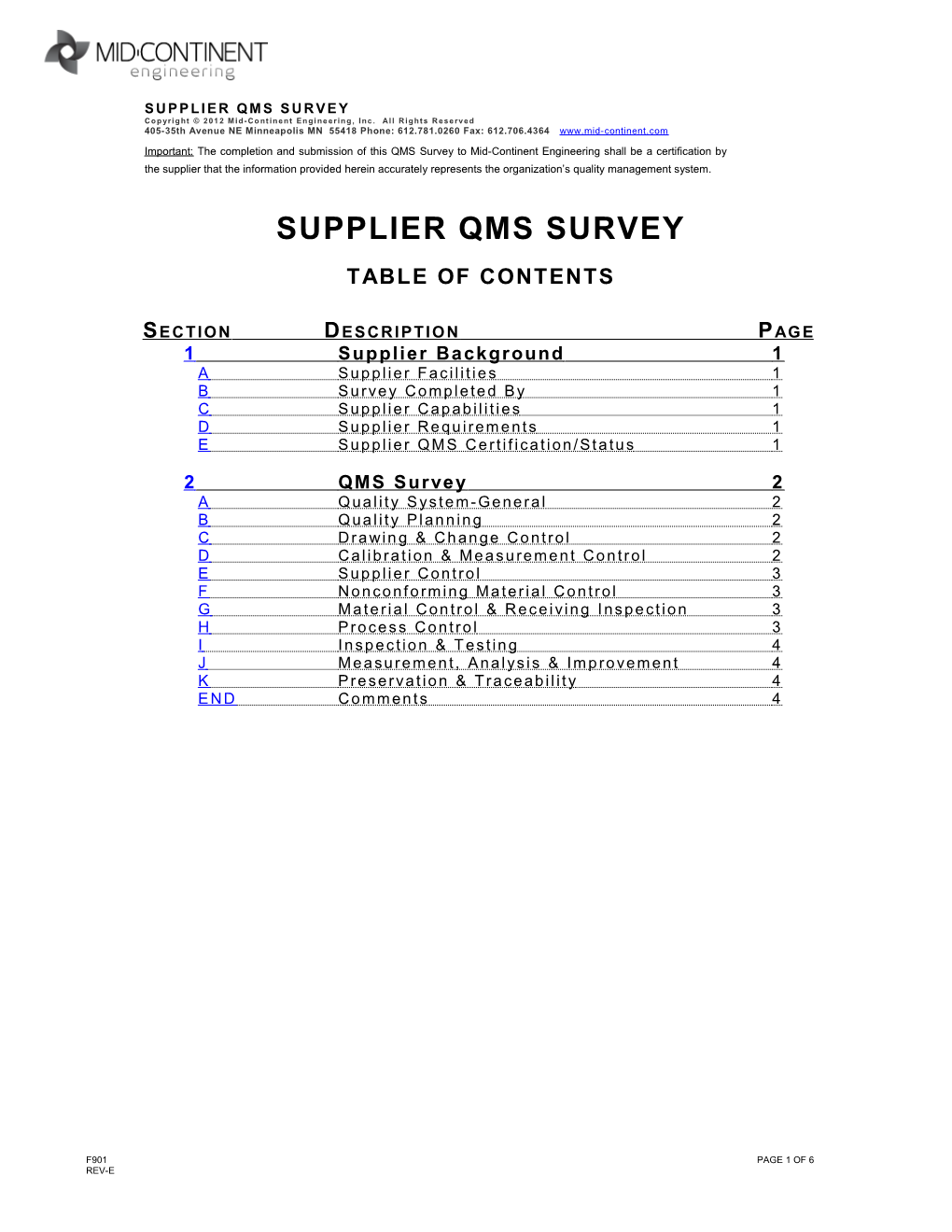

SUPPLIER QMS SURVEY TABLE OF CONTENTS

SECTION DESCRIPTION P AG E 1 Supplier Background 1 A S up p lie r Fa cilit ie s 1 B S u rve y Co mp le te d B y 1 C S up p lie r Cap ab ilit ie s 1 D S up p lie r Re qu irem e nt s 1 E S up p lie r Q MS Ce rt if ica t ion / St a tu s 1

2 QMS Survey 2 A Q ua lit y S yst e m -Ge ne ra l 2 B Q ua lit y P lan n in g 2 C Dra win g & Ch an ge Co nt ro l 2 D Ca lib ra t ion & Me a su re me n t Co n t ro l 2 E S up p lie r Con t ro l 3 F No n co nf o rm in g Ma te ria l Co n t ro l 3 G Ma t e ria l Con t ro l & Re ce ivin g I nsp e ct io n 3 H P ro ce ss Co nt ro l 3 I I n sp e ct io n & T est in g 4 J Me a su re me n t, A na lysis & Im p ro ve m en t 4 K P re se rva t io n & Tra ce ab ilit y 4 E ND Co mm en t s 4

F901 PAGE 1 OF 6 REV-E SECTION 1 SUPPLIER BACKGROUND Supplier Code: A SUPPLIER FACILITIES B SURVEY COMPLETED BY Company: Name: Date: Address: Position: Phone: Fax: City: State: Zip: Email: Phone: Fax: Comments: Website: Fed Tax ID: - DUNN/BRADSTREET NO: C SUPPLIER CAPABILITIES Principal Products/Services: Years in Business: Key Processes: Mfg Area (sq/ft): Major Customers: PERSONNEL NO. EMPLOYED RESPONSIBLE PERSON/POSITION Engineering: / Production: / QA/Inspection: / D SUPPLIER REQUIREMENTS—PURCHASE ORDER & QUALITY CODES Purchase Order Requirements . A Mid-Continent Engineering (MCE) Purchase Order contains certain requirements a Supplier must fulfill to meet our minimum expectations under an order (i.e. part number, quantity, cost, destination, delivery date, etc.). . Additional quality requirements apply to most Purchase Orders—these requirements are listed as Quality Codes. Quality Code Requirements . One or more Quality Codes (i.e. A2-1, B3, C1, etc.) may be listed on a Purchase Order. . Quality Codes individually represent certain mandatory quality requirements applicable to the order. . A complete description for each Quality Code can be accessed on MCE’s website, http://www.mid-continent.com. If direct link not working, copy/paste address into browser. Hover COMPANY dropdown and click QUALITY SYSTEM. Choose ‘Supplier Quality Codes’ under RELATED LINKS on left to access latest revision. Revision Status . Quality Codes are subject to revision without notice. . It is the supplier’s responsibility to apply Quality Codes from the most current (online) list.

Routinely verify all applicable Quality Codes to the latest revision at: http://www.mid-continent.com

Check ‘Yes’ to indicate you have read & understand the above YES ACKNOWLEDGMENT information pertaining to Supplier Requirements/Quality Codes: E SUPPLIER QMS CERTIFICATION/STATUS

CURRENT QUALITY SYSTEM CERTIFICATION/PROCESS ACCREDITATION – CHECK/LIST ANY THAT APPLY

REGISTRAR: ISO 9001 (GENERIC) ISO 13485 (MED DEVICE) EXPIRATION DATE: AS9100 (AEROSPACE) ISO/TS 16949 (AUTOMOTIVE)

ORIG. DATE CERTIFIED: ISO/IEC17025 (TESTING) OTHER: IF CERTIFIED TO ISO OR OTHER INDUSTRY-RECOGNIZED QUALITY STANDARD STOP HERE AND ATTACH COPY OF REGISTRATION CERTIFICATE

OTHERWISE, COMPLETE BALANCE OF SURVEY (SECTION 2)

F901 PAGE 2 OF 6 REV-E SECTION 2 QMS SURVEY A QUALITY SYSTEM—GENERAL YES NO N/A 1. Do you have a quality manual defining your quality management system? Is your quality system based on a recognized quality standard (i.e. ISO 2. 9000, AS9100, etc)? If yes, list: Do you have a holding area with controlled access in which to store NCM 3. until disposition? Are there written, implemented, current procedures defining the roles 4. and responsibilities related to quality? 5. Do you have a formal, quality related training program? Do you perform periodic internal quality system audits to assure 6. compliance with written procedures? Do you track measures of customer satisfaction related to quality 7. delivery, etc.? 8. Do you have a quality cost tracking system? Does management regularly review the effectiveness of the quality 9. system? Are quality related records maintained a minimum of seven year's from 10. completion of an order? B QUALITY PLANNING YES NO N/A Do you review purchase orders and change orders for technical and 1. quality requirements prior to manufacture? Do you take assurances that the latest drawing(s) and specification(s) 2. are on file prior to production? C DRAWING & CHANGE CONTROL YES NO N/A Are engineering drawings, specifications, procedures and instructions 1. available to all personnel? 2. Are there written procedures describing change control? Do your procedures ensure the use of only current, complete and 3. adequate engineering drawings? Are obsolete drawings, specifications, procedures, instructions, and 4. documents promptly removed from use? Do your procedures require you to obtain customer and/or government 5. approval for a proposed change or deviation? D CALIBRATION & MEASUREMENT CONTROL YES NO N/A Is there a system for calibrating all measuring and test equipment used 1. for the acceptance of product? Is calibration performed under latest revisions of ANSI/NCSL Z540, 2. ISO/IEC 17025, and relevant requirements of ISO 9000 series of standards? Are measurement standards used for calibration of measuring equipment and are such standards traceable to international or national 3. measurement standards(i.e. U.S. NIST or applicable country national standards organization)? Is the environment underwhich calibration is performed defined and 4. controlled to the extent necessary to assure required accuracy? Is there a procedure for checking (and recording) the validity of previous measuring results when the equipment is found not to conform 5. to requirements and is appropriate corrective action taken on any affected equipment or product?

F901 PAGE 3 OF 6 REV-E Are written calibration procedures available and in use for calibration 6. of all measurement & test equipment and standards? Is all measuring equipment uniquely identified such that its 7. calibration status can be determined? Are records of calibration maintained for each unit of measuring and 8. test equipment? Is each unit of measuring and test equipment identified with date 9. calibrated, calibration due date, and any use limitations? Are calibration intervals established in terms of calendar time, usage 10. or a combination of both? 11. Are calibration frequencies periodically reviewed for adequacy? E SUPPLIER CONTROL YES NO N/A Do you have a selection process for suppliers, subcontractors and 1. processors based on the ability to meet quality and contract requirements? Do you maintain an Approved Supplier List that includes the scope of 2. the approval? Do you and your subcontractors use customer-approved special process 3. sources where required by contract? Do you periodically review supplier performance and use these reviews 4. as a basis for establishing the level of controls to be implemented? Do you require, document and obtain corrective action from your 5. suppliers for nonconforming materials, parts or services or unsatisfactory performance? Do your purchase orders clearly describe the product ordered and the 6. applicable requirements such as manufacturing, inspection, reliability and quality systems? Do your purchase orders adequately flow down your requirements to your 7. suppliers? Do your purchase orders contain a right of entry clause for you and 8. your customers (including regulatory bodies)? Are your purchasing documents reviewed for completeness and adequacy of 9. specified requirements prior to release? Does your quality assurance or other responsible personnel regularly 10. review the quality performance of your suppliers? Does your quality assurance or other responsible personnel have the 11. authority to approve or disapprove suppliers for use? F NONCONFORMING MATERIAL CONTROL YES NO N/A 1. Do you have a procedure for controlling nonconforming material? Do you promptly document and clearly identify nonconforming material 2. and segregate it from acceptable material? Do you have a secure holding area with controlled access in which to 3. store nonconforming material until its review and disposition? Do you have a system for obtaining your customer's review and 4. disposition of all nonconforming materials that cannot be reworked to customer requirements or are deemed obvious scrap? Is all material with final disposition of "scrap" mutilated before 5. release from the segregate holding area? Do you have procedures in place to notify customers in writing when a 6. nonconformance is found in your process or products that may affect product already delivered?

F901 PAGE 4 OF 6 REV-E Do you require formal, documented corrective action for significant or 7. repeat occurrences? G MATERIAL CONTROL & RECEIVING INSPECTION YES NO N/A Are all parts, raw materials, supplies, or services inspected upon 1. receipt to ensure conformance to purchase contract requirements? Are certifications for all raw materials checked 100% against the 2. applicable specifications to verify conformity to those specifications? Do you send raw material samples to an independent laboratory at 3. regular intervals in order to confirm its conformance to the applicable specification? Do you require your suppliers to exercise an equivalent control of raw 4. material? Are incoming materials properly identified and controlled until 5. inspection acceptance is indicated? Is heat lot/batch number identification clearly marked and maintained 6. on stored materials? H PROCESS CONTROL YES NO N/A Are shop orders, travelers, work instructions, etc., used to describe 1. manufacturing operations? Are detailed work instructions/procedures used for complex or critical 2. operations (e.g. NDT, plating, assembly, etc.)? Do work instructions and process specifications contain adequate 3. quality requirements? Is the acceptance status of product clearly identified at all phases of 4. production? Is product identified and traceable to drawings, specifications, 5. certifications or other documents during all phases of receipt, production, storage and delivery? Does your system provide for traceability through batch or serial 6. numbers when specified by purchase order? 7. Are records maintained covering the processes, personnel and equipment? I INSPECTION & TESTING YES NO N/A 1. Do finished products receive a final inspection/test/audit? Are documented inspection/test procedures describing characteristics to 2. be inspected and inspection level used? Are the results of all inspections and tests documented and do the records include as a minimum the number of pieces accepted/rejected, 3. the identity of the person performing the inspection/test and the date of inspection/test? Are there controls in place to assure that the products are not 4. released to storage or shipment until all inspections and tests are satisfactorily completed? J MEASUREMENT, ANALYSIS & IMPROVEMENT YES NO N/A 1. Is sampling inspection performed? Is Sampling Performed To A Recognized Statistical Sampling Plan (i.e. MIL-STD-105, MIL-STD-1916 Or ANSI/ASQC Z1.4)? 2. Yes? To what specification/standard? No? Describe:

F901 PAGE 5 OF 6 REV-E Do you have a formal SPC program in place for monitoring and 3. controlling variation for key product characteristics and process parameters? Have you conducted SPC training for personnel involved in SPC 4. implementation? Have you identified your key manufacturing processes and process 5. parameters? 6. Are control charts used in the applicable process work areas real time? 7. Is capability data being used to improve the process? K PRESERVATION & TRACEABILITY YES NO N/A 1. Are limited shelf life items identified and controlled? Is customer-owned material/property clearly identified, safeguarded, 2. and verified prior to use? Where applicable, is customer product (and constituent parts) properly 3. identified/marked with all customer-required information before storage or deliver? Does your storage area provide sufficient protection for stored 4. materials? Are all customer requirements verified as complete on all products 5. prepared for delivery? Is there a system to ensure that all packing lists and applicable 6. quality documentation (as required by contract) is included with all shipments and that all items are packaged and marked per contract? Is packaging and marking performed in accordance with general or part 7. specific packaging instructions? Where required, are batch/lot serial numbers recorded and traceable to 8. shipping documents? If required, can raw material certifications, product inspection 9. records, etc., be provided with shipments?

COMMENTS

END

THANK YOU FOR TAKING THE TIME TO COMPLETE OUR QMS SUPPLIER SURVEY! The information you provide is an important and necessary part of our quality partnership and is, as always, confidential. Please contact Mid-Continent Engineering, Quality Department, with any questions or comments. 612.781.0260

F901 PAGE 6 OF 6 REV-E