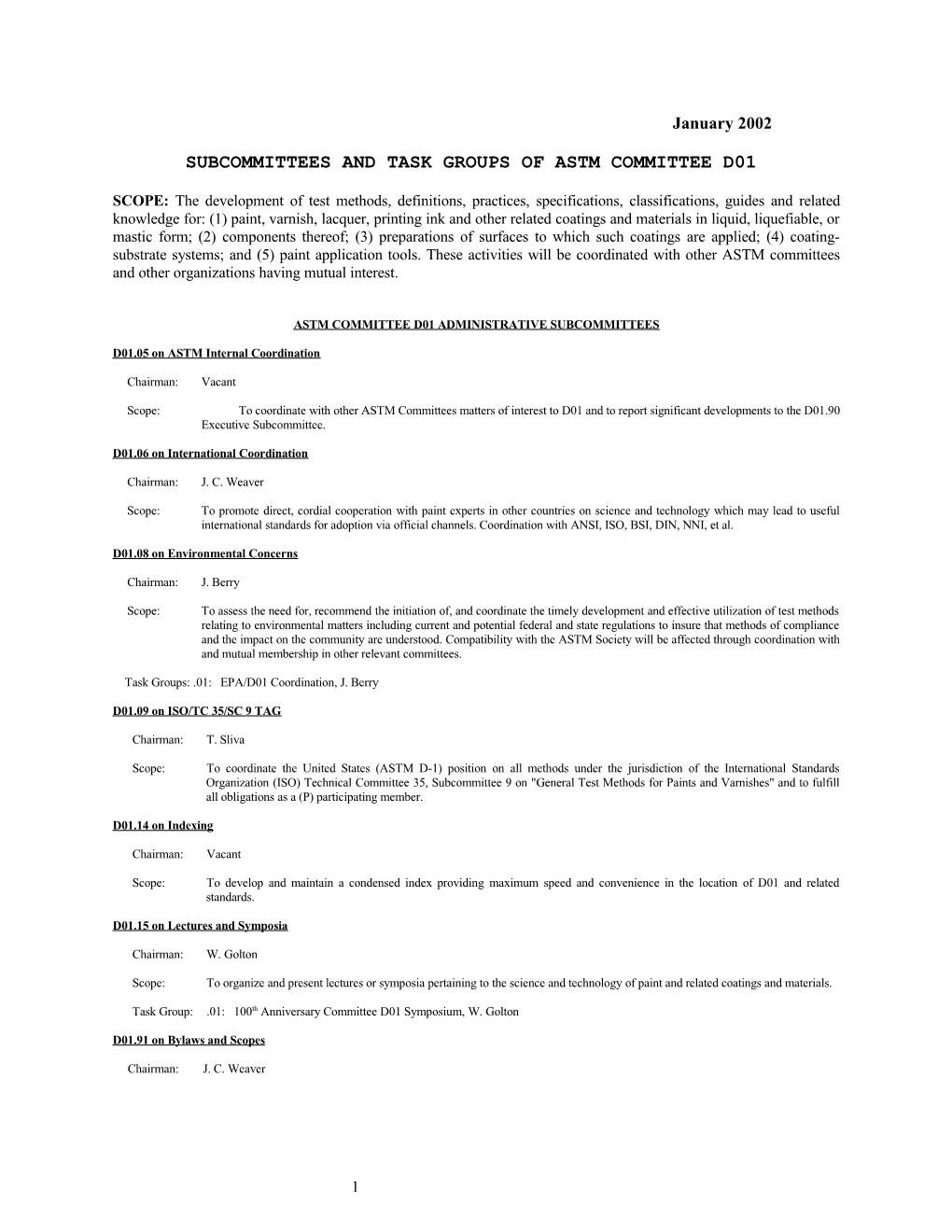

January 2002

SUBCOMMITTEES AND TASK GROUPS OF ASTM COMMITTEE D01

SCOPE: The development of test methods, definitions, practices, specifications, classifications, guides and related knowledge for: (1) paint, varnish, lacquer, printing ink and other related coatings and materials in liquid, liquefiable, or mastic form; (2) components thereof; (3) preparations of surfaces to which such coatings are applied; (4) coating- substrate systems; and (5) paint application tools. These activities will be coordinated with other ASTM committees and other organizations having mutual interest.

ASTM COMMITTEE D01 ADMINISTRATIVE SUBCOMMITTEES

D01.05 on ASTM Internal Coordination

Chairman: Vacant

Scope: To coordinate with other ASTM Committees matters of interest to D01 and to report significant developments to the D01.90 Executive Subcommittee.

D01.06 on International Coordination

Chairman: J. C. Weaver

Scope: To promote direct, cordial cooperation with paint experts in other countries on science and technology which may lead to useful international standards for adoption via official channels. Coordination with ANSI, ISO, BSI, DIN, NNI, et al.

D01.08 on Environmental Concerns

Chairman: J. Berry

Scope: To assess the need for, recommend the initiation of, and coordinate the timely development and effective utilization of test methods relating to environmental matters including current and potential federal and state regulations to insure that methods of compliance and the impact on the community are understood. Compatibility with the ASTM Society will be affected through coordination with and mutual membership in other relevant committees.

Task Groups: .01: EPA/D01 Coordination, J. Berry

D01.09 on ISO/TC 35/SC 9 TAG

Chairman: T. Sliva

Scope: To coordinate the United States (ASTM D-1) position on all methods under the jurisdiction of the International Standards Organization (ISO) Technical Committee 35, Subcommittee 9 on "General Test Methods for Paints and Varnishes" and to fulfill all obligations as a (P) participating member.

D01.14 on Indexing

Chairman: Vacant

Scope: To develop and maintain a condensed index providing maximum speed and convenience in the location of D01 and related standards.

D01.15 on Lectures and Symposia

Chairman: W. Golton

Scope: To organize and present lectures or symposia pertaining to the science and technology of paint and related coatings and materials.

Task Group: .01: 100th Anniversary Committee D01 Symposium, W. Golton

D01.91 on Bylaws and Scopes

Chairman: J. C. Weaver

1 Scope: To prepare revisions and amendments of the bylaws of ASTM Committee D01, when required, consistent with current ASTM policies. To review scopes of other subcommittees of D01.

2 D01.93 on Meetings and Sites

Chairman: H. Fujimoto

Scope: To work with the Headquarters Meetings Dept. to schedule D01 meetings at times and places fitting the needs and requirements of D01.

D01.94 on Awards and Memorials

Chairman: T. Sliva

Scope: To recommend to the D01.90 Executive Subcommittee deserving candidates whose exemplary contributions and/or activities merit recognition via the various awards available to Committee D01 members, and to propose appropriate memorial resolutions for deceased Committee D01 members.

D01.95 on Promotion

Chairman: L. Pattison

Scope: To develop strategies and make recommendations for ways to promote the interests and activities of Committee D01, in respect to the following areas: New memberships, Fund-raising (technical, administrative, ISO ,etc.), and Publicity.

Task Groups: .01: New Member/Membership Development .02: Fund Raising, T. Sliva .03: Publicity, R. Montemayor

D01.96 on Coatings Research and Planning

Chairman: G. Pilcher

Scope: To address long term planning needs for D01. To stimulate interest in and promote discussion of research needed to provide or strengthen the technical bases for coatings standards. To provide a mechanism for the stimulating and writing of proposals for standards-related research for submission to ASTM's Contract and Grant Management and for evaluating D-1 proposals to be submitted to ASTM's Contract and Grant Management.

ASTM COMMITTEE D01 TECHNICAL SUBCOMMITTEES

D01.16 on Definitions

Chairman: J. Bryson

Scope: the subcommittee gathers, coordinates, and edits terms and definitions of interest to developers and users of Committee D01 standards.

D01.20 on Quality Assurance & Statistics

Chairman: R. Morrison

Scope: To develop recommended quality assurance practices pertaining to raw materials, statistical process control, sampling, and testing of paints and related materials to insure consistency of products. To provide advice, upon request, on precision and bias statements in new and revised test methods prepared by other subcommittees of D01. To develop recommended practices for statistical analysis of inter- and intralaboratory testing of coatings and related raw materials.

Task Group: .01: Interlaboratory Studies, R. Morrison

3 D01.21 on Chemical Analysis of Paints and Paint Materials

Chairman: H. Fujimoto

Scope: Develop standard test methods and practices for the analysis of coatings and materials used in the manufacture of coatings, using instrumental, physical and chemical methods, which are not within the scope of other subcommittees.

Task Groups: .12: Coordination of VOC Standards, K. Fujimoto .13: Coordination of VOC Standards and Information, R. Matejka .14: New Publications and VOC Workshops, W. Golton .16: Laision between D01.21 and ISO/TC 35/SC 10/WG 4, J. Phillips .17: Clarification of EPA Method 311, R. Nelson .23: Thermoplastic Traffic Markings, J. O'Brien .24: Revision of D 2369 Volatile Content in Paints, M. Sites .24A: Ion Chromatography/Electrocoat Samples .24B: VOC of Fast Cure Multicomponent Paints, K. Fujimoto .25A: VOC Release from Applied Coatings, L. Pattison .26: Review of D 2697 VNV, Helium Pycnometer .26B: Determination of Envelope Density Using a Pycnometer .27A: VOC of Aerosols, R. Osterman .46: X-Ray Analysis of Pigments .50: Exempt Volatile Compounds by Solid Phase Micro-Extraction, M. Wills .51: Determination of Formaldehyde in Paint, J. Phillips .52 Paint Solvent Analysis by Gas Chromatography, J. Benga .52A Hazardous Air Pollutants (HAPs) by HS/GC/MS, S. Ramesh .54: Water in Paints by Karl Fischer Method, W. Golton 54A: VOC Credit for Cure Water, S. Brunner .54B: Revision of D 3792, Water in Paints by Gas Chromatograph, J. Benga .55: Exempt Solvents in Paints by Gas Chromatography, J. Benga .55A: Exempt Volatile Compounds by GC/MS, S. Ramesh .56: Revision of D 3960, VOC Calculations in Paints, M. Sites .57: Revision of D 4457, Analysis of Halohydrocarbons, J. Benga .80: Exploratory Analytical Research, K. Fujimoto

D01.22 on Health and Safety

Chairman: R. Osterman

Scope: The health and safety subcommittee shall develop standards (test methods and recommended practices) to determine the hazardous properties of materials within the jurisdiction of ASTM D01. The subcommittee shall provide coordination between ASTM Committee D01 and other ASTM committees concerned with similar standards and shall provide information concerning regulations and applicable standards, to D01.90 members.

Task Groups: .01: Flammability and Flash Point, M. Harding .02: Chromates-Health and Safety, J. Brezinski .03: Precautionary Statements, J. Brezinski

D01.23 on Physical Properties of Applied Paint Films

Chairman: P. Guevin

Scope: To develop test methods, definitions, and recommended practices for determining the physical properties of wet and dry films of paint, varnishes, lacquers, and related coatings and materials. The subcommittee shall provide coordination between ASTM Committee D01 and other ASTM committees with similar standards and shall provide information on physical testing instruments, procedures, regulations and acceptable standards, to all concerned groups.

4 Task Groups: .08: Preparation of Uniform Films .10: Adhesion, G. Nelson .11: Wet Film Thickness, P. Guevin .12: Dry Film Thickness, P. Guevin (Temporary) .14: Hardness, Mar and Abrasion Resistance, P. Guevin (Temporary) .15: Slip Resistance, P. Guevin (Temporary) .16: Water Vapor Transmission, T. Sliva .18: Flexibility, P. Guevin .19: Dry Time, T. Sliva .20: Exploratory Research, P. Guevin .21: Contact Angle Measurement, D. Weldon

D01.24 on Physical Properties of Liquid Paints and Paint Materials

Chairman: S. Ahrens

Scope: To develop test methods, definitions, and recommended practices for determining the physical properties of liquid paints, varnishes, lacquers, and related materials.

Task Groups: .18: Dispersion Phenomena, R. Morrison .19: Viscosity by Efflux Cups, S. Ahrens (Temporary) .20: Rotational Viscometers, S. Ahrens (Temporary) .21: Stormer Viscometer, S. Ahrens (Temporary) .22: Density, W. Golton .23: High Shear Viscosity, S. D. Ahrens (Temporary) .30: Calculation of Formulation Physical Constants, R. Diem .31: Viscosity by ISO Cup, S. D. Ahrens (Temporary) .32: Viscosity by Concentric Cylinder Viscometers, (Vacant) .33: Odor Evaluation, D. Darr .34: Viscosity by Falling Needle Viscometer, N. Park

D01.25 on Evaluation of Weathering Effects and Coatings Defects

Chairman: M. Crewdson

Scope: To create and maintain standards and any related documents concerned with the evaluation of weathering and corrosion effects and coating defects. The work of this subcommittee will be coordinated with other ASTM committees and other organizations having mutual interests.

Task Groups: .01: Pictorial Standards, M. Crewdson .02: Visual Evaluations, M. Crewdson .03: Image Analysis, F. Lee .04: Mildew Evaluation, M. Crewdson

D01.26 on Optical Properties

Chairman: A. Kravetz

Scope: To develop test methods and recommended practices for the determination of optical and appearance properties of paint.

Task Groups: .02: Color Measurement, E. C. Carter .06: Hiding Power, R. Diem .11: Gloss and Goniophotometry, R. Harold and S. Ahrens .24: Tinting Strength, R. K. Morrison

D01.27 on Accelerated Testing

Chairman: D. Grossman

Scope: To develop standards or recommended practices for evaluating film performance of applied paint and related finishes, comprising resistance to accelerated deterioration, normal and abnormal environments, and with consideration to film/substrate relationships which affect the useful service life of the coating.

5 Task Groups: .02: Water Tests, D. Grossman .04: Light and Water Exposure Apparatus, L. Thieben .10: Accelerated Outdoor Weathering, J. Robbins, III .12: Detergent Resistance, D. Grossman .18: Outdoor Weathering, J. Martin .28: Filiform Corrosion, F. Lutze .29: Test Substrates, D. Grossman .30: Corrosion Testing (Automotive), C. Meade .31: Corrosion Testing (Non-Automotive), R. Singleton .32 Electrochemical Impedance, M. Yaffe

D01.28 on Biodeterioration

Chairman: J. Hinkle

Scope: To develop standards for evaluating the susceptibility of organic coatings and components thereof to biodeterioration.

Task Groups: .01: Package Stability, J. Hinkle .02: Rapid Determination of Enzymes, L. Sadasivan .03: Microbial Quality of Raw materials, J. Hinkle .04: Resistance of Paint Films to Algae Attack, K. Roberts .05: Humidity ChamberCExterior Paints, J. Hinkle .07: Revision of D 3274 (Defacement Ratings), M. Crewdson

D01.31 on Pigment Specifications

Chairman: R. Schiller

Scope: Pigments as such and dispersed in a paint vehicle, but not as complete paint products. The specific practices and procedures for obtaining pigment properties are also the responsibility of D01.31, i.e. particle size and specific gravity.

Task Groups: .01: Inorganic Coloring Pigments, (Vacant) .02: Organic Coloring Pigments, (Vacant) .03: Metallic Powdered Pigments, D. Ruddick .04: Antifouling Pigments, A. Chasan .05: Metallic Flake Pigments, L. Pitchford .06: Special Pigments, W. Spangenberg .07: Extenders, (Vacant) .08: Titanium Dioxide, R. Hopkins .09: Carbon Pigments, (Vacant) .11: Lead-Containing Pigments, W. Spangenberg .12: Zinc-Containing Pigments, K. Edwards .13: ISO Pigment Coordination, R. Schiller .14: Coordination with ASTM Committee E-34, (Vacant) .15: Micaceous Iron Oxide, C. Hendry

D01.32 on Drying Oils

Chairman: Vacant

Scope: Specifications and methods of test covering drying, semi-drying, and saturated oils commonly used in the protective coating industry. Also included are similarly related fatty acids and fatty amine products.

D01.33 on Polymers and Resins

Chairman: Vacant

Scope: All varnishes, resins, shellac, and other major nonvolatile film-forming materials and solutions or suspensions thereof not within the scope of other subcommittees and for use only as vehicle or media for paint products formulated for them.

6 D01.34 on Naval Stores

Chairman: J. Russell

Scope:

Task Groups: .01: Capillary Gas Chromatography of Rosins and Fatty Acids, R. De Priest .04: Iodine Value of Tall Oil Fatty Acids Using Isooctane as a Solvent, J. Bowers .05: Softening Point by Ring and Ball Apparatus, P. Zawislak .06: Color Measurements by Instrumental Methods, W. Mark .07: Capillary GC of Turpentine, D. Stewart .08: Analysis of Naval Stores Products by Near Infra Red Measurements, R. De Priest .09: Harmonization, J. Russell .10: Anthraquinone in Crude Tall Oil, R. De Priest

D01.35 on Solvents, Plasticizers and Chemical Intermediates

Chairman: R. Montemayor

Scope: Solvents, plasticizers, and those materials (not within the scope of other subcommittees) which react chemically to produce paints and paint material.

Task Groups: .10: Solvents-Hydrocarbons and Ketones, R. Hinrichs .20: Reactive Monomers, J. Frugé .30: Chemical Intermediates, (Vacant) .40: Plasticizers and Ester Solvents, J. Lawniczak .50: Coordination, (Vacant) .60: Method Development, R. Montemayor

D01.36 on Cellulose & Cellulose Derivatives

Chairman: G. Moore

Scope: The definition of terms and the study and formulation of test methods and specifications covering cellulose for chemical conversion and cellulose derivatives, these activities to be coordinated in cooperation with relevant committees in ASTM and outside organizations.

D01.37 on Ink Vehicles

Chairman: A. Scarlatti

Scope: To develop test methods, nomenclature, definitions, recommended practices, instrumental standards and specifications for printing ink vehicles, varnishes, and components thereof.

Task Groups: .01: Resin Solutions, J. Head .06: Ink Vehicle Wetability, M. Fuchs .07: Resin/Solvent Compatibility, P. Massot .08: New Membership, A. Asdel .09: Alkyd Compatibility of Ink Resins, D. Weisel .10: Rheology of Ink Vehicles, D. Weisel .11: Guide for Ink Vehicles, J. Newton .12: Printing Ink Vehicle Terms, G. Kowalczyk .13: Dilution of Gelled Vehicles, V. Spencer .14: Liquid Ink Vehicles, R. Czarnecki .15: Technical Liaison, M. Kramer/P. Massott

D01.38 on Hydrocarbon Resins

Chairman: J. Bryson

Scope: To develop standards for characterizing hydrocarbon resins.

7 Task Groups: .01: Terminology, R. Allen .02: Softening Point, P. Zawislak .03: Color, R. Allen .04: Cloud Point/Compatibility, L. Graves .05: Viscosity, P. Zawislak .06: Stability, L. Graves .07: New Instrumental Test Methods, A. Kravez

D01.42 on Architectural Coatings

Chairman: L. Adams

Scope: Architectural Paints used on-site in initial and repeat painting of the interiors and exteriors of buildings, and not within the scope of other subcommittees.

Task Groups: .05: Adhesion of Latex Paints to Chalky Surfaces, (Vacant) .21: New Project Planning, L. Adams .22: Guides for Testing Architectural Coatings, L. Adams .25: Scrub Resistance of Architectural Coatings, T. Sliva .26: Burnish Resistance of Latex Paints, L. Adams .30: Wet Edge Time of Latex Paints, J. Cogar .36: Foam Resistance of Latex Paints, D. Rabkewych .37: Low Temperature Application of Latex Paints, (Vacant) .38: Tannin Stain Resistance, D. Marschall

D01.44 on Traffic Coatings

Chairman: J. Kalchbrenner

Scope: Liquid striping coatings used on highways, which afford day and night traffic lane delineation.

Task Groups: .01: Thermoplastic, J. O'Brien .02: Traffic Marking Materials, C. Winchester .03: Night Visibility, J. Kalchbrenner

D01.45 on Marine Coatings

Chairman: E. Haslbeck

Scope: The development of test methods, practices, specifications, guides and related knowledge for the selection and uses of marine coatings in the field and laboratory insofar as these test methods do not fall in the scope of other subcommittees of D01. Marine coatings are defined as coatings applied to substrata that will be exposed to environments comprising sea water, brackish water, or the contiguous, salt-laden atmosphere, either continuously or periodically.

Task Groups: .12: Standard Practice for Testing Marine Coating Systems in Air/Water Cycling OPEN .15: Standard Method for Measuring Adhesion of Fouling to Coated Surfaces (G. W. Swain) .17: Wet Copper Analysis (C. Anthony) .18: Rating Antifouling Performance (C. Perez) .19: Antifouling Coating Performance Round Robin (C. Perez) .20: Measuring Release Rates of Organic Biocides (J. E. Hickey) .21: Copper Release Rate Round Robin (E. Haslbeck) .22: Measuring Release Rate of Copper from Antifouling Coatings (C. Anthony) .23: Measuring Adhesion of Synthetic Adhesive to Fouling Release Coatings (G.W. Swain) .24 : ISO TC35/SC9/WG27 – ASTM D01.45 Interaction (E.Haslbeck)

D01.46 on Industrial Protective Coatings

Chairman: L. Smith

Scope: To study paints applied to metals on-site of structures and buildings, especially where subject to corrosive environments, as industrial, urban, or marine environments.

8 Task Groups: .01: Coordination with SSPC, (Vacant) .02: Surface Preparation, D. Weldon .03: Repainting, G. Gardner .04: Pull-Off Adhesion, H. Robins .07: Inspection, L. Smith .10: Condition Assessment, A. Beitelman .12 Sampling, L. Smith .13 Guide for Testing, J. T. Cheng .14 Chemical Immersion, H. Robins .15: Graffiti, W. Ketola .16: Freeze/Thaw, R. Eritano

D01.47 on Masonry Treatments

Chairman: K. Klosowski

Scope: To develop test methods for the evaluation of short and long term performance of water repellent treatments applied to masonry surfaces. To develop guides for a) evaluating the condition of masonry substrates to establish the need for treatment, b) surface preparation, and c) application of treatments.

Tasks Groups: .01: Water Repellency of Treated Masonry,Brick , L. Danforth .02: Stain Resistance of Treated Substrates, J. Linert .03: Nonvolatile Content of Silane, Siloxane, and Silane/Siloxane Blends Used in Masonry Water Repellents, T. J. Sliva .05: Water Vapor Transmission of Treated Substrates, T. J. Sliva .06: Freeze/Thaw Resistance of Treated Masonry, L. Stark-Kasley .07: Alkali Resistance of Masonry Treatments, B. Bergland .08: Rapid Chloride Ion Intrusion, (Vacant) .10: Evaluation of Field Applied Treatment, K. Klosowski-Fragetti .11: Research and Planning, K. Klosowski-Fragetti .12: Measurement of Water Absorption into Treated Masonry Using a Water Uptake Tube, K. Klosowski-Fragetti .13: Stain Resistance of Treated Masonry, J. Longoria

D01.48 on Pipe Coatings

Chairman: D. Kathrein

Scope: Develop and maintain standards relating to the durability of pipeline coatings and linings.

D01.51 on Powder Coatings

Chairman: J. Hagerlin

Scope: To promote knowledgeable design, manufacture and use of coating powders through the development of test methods, practices, and guides that are based upon experience and proven experimentation in response to the needs of industry and government. To coordinate publications with other standards writing organizations for optimum consistency and clarity.

Task Groups: .01: D3451 Testing Coating Powders and Powder Coatings, J. Hadden .02: D6441 Measuring the Hiding Power of Powder Coatings , J. Peters .03: ISO 8130-10 Spray Characteristics of Coating Powders, open .04: D5382 Optical Properties of Powder Coatings, J. Hagerlin .05: D5965 Specific Gravity of Coating Powders, R. Boni .06: D5861 Significance of Particle Size Measurements of Coating Powders, J. Pont .07: Consideration of New Methods, open .08: Liaison to Powder Coating Institute (PCI), D. Hammerton .09: Liaison to ISO/TC 35/SC 9/WG 16 Powder Coatings, R. Chambers .10: D2967 Edge Coverage of Coating Powders, R. Boni .11: D3214 Coating Powders Used for Electrical Insulation, J. Hagerlin .12: D4217 Gel Time of Thermosetting Coating Powder, J. Pont .13: D4242 Glass Plate Flow for Thermosetting Coating Powders, J. Pont .14: Consideration of Cure Volatiles of Coating Powders, J. Berry .15: Consideration of Pre-Bake Thickness of Coating Powders , J. Walker

9 D01.52 on Factory Coated Wood Products

Chairman: L. Wagner

Scope: To develop coordinated methods of test for factory applied coatings on wood and wood composite products. This scope does not include the wood alone, the paint alone, or methods of application, insofar as these fall under the jurisdiction of other ASTM groups.

Task Groups: B: Hardboard, S. B. Schroeder .15: Film Thickness, S. B. Schroeder .18: Accelerated Exposure, T. Rieth .20: Cement Bonded Wood Composites, S. B. Schroeder

D01.53 on Coil Coated Metal

Chairman: D. Cocuzzi

Scope: To develop methods of test for the finishing system of factory-applied organic coatings to metal strip which, after coating, is subsequently drawn, stamped, or formed. Examples include thermosetting enamels, thermoplastic coatings such as plastisols, organosols, and plastic films applied to steel, galvanized steel, or aluminum surfaces.

Task Groups: .01: Pretreatment of Substrates, D. W. Fudge .03: Accelerated Weathering, D. A. Cocuzzi .04: Dry Film Thickness of Coil Coating, G. R. Pilcher .05: Solvent Resistance Tester, J. C. Larsen

D01.55 on Factory-Applied Coatings on Preformed Products

Chairman: R. Diem

Scope: To study factory-applied coatings for products in the form of ultimate use (not post-formed), including the method of coating and substrate such as metal, wood, (except that under the jurisdiction of D01.52 on Factory-Coated Wood Building Products), paper, plastic, et al.

Task Groups: .06: Coatings on Plastics, M. A. Lutterbach .08: Transfer Efficiency - Laboratory Conditions, R. S Diem .09: Transfer Efficiency - Production Conditions, R. S. Diem .10: VOC Determination in Radiation-Cured Coatings, R. Beuhner .11: Mar-Resistance of Automotive Clearcoats, R. Diem .13: Exposure of Automotive Coatings to Fleet Service Conditions, R. Diem

D01.56 on Printing Inks

Chairman: J. Fetsko

Scope: To develop test methods, nomenclature, definitions, recommended practices, instrumental standards and specifications for: 1) printing inks, 2) components thereof, and 3) ink/substrate systems.

Task Groups: .01: Fineness of Grind, R. Incontro .02: Lightfastness of Printed Matter, J. M. Fetsko .04: Viscosity of Paste Inks, J. M. Fetsko .06: Apparent Tack, A. Scarlatti .09: Tinting Strength of Paste Inks, J. M. Fetsko .10: Ink Emulsification, P. I. Ford .11: Nonvolatile Content of Printing Inks, B. E. Blom .12: Viscosity of Liquid Inks, J. W. Daugherty .13: Ink Mileage, D. Ness .14: Setting of Heatset Inks, D. Ness .15: Density (wt./gal.) of Printing Pastes, P. I. Ford .17: Guide for Printing Inks, J. M. Fetsko .18: Heat Resistance, D. Duncan .20: Technical Coordination, D. Rich .21: Print Abrasion (CAT), G. Vandermeersche .22: Drying of Oxidizable Inks, B. E. Blom .24: Grit Determination, M. Fuchs .25: Degree of Radiation Curing, E. Kobylarz .26: Chemical Resistance, M. Fuchs

10 .28: Tinting Strength of Aqueous Inks, D. Ness .29: Memberships, J. W. Daugherty .30: Optical Density, E. Kobylarz .31: Print Transparency, Inactive .32: Laboratory Print Preparation, D. Ness/V. Waltz .33: Print Gloss, J. Daugherty .34: Print Problem Terminology, D. Duncan .35: Ink Tack Changes on Substrates, J. Jacques .36: VOCs of Printing Inks, P. I. Ford .37: VOCs of Energy Curable Inks, E. Kobylarz .38: Printing Ink Terminology, R. Czarmecki/S. Field

D01.57 on Artists' Paints and Related Materials

Chairman: M. Gottsegen

Scope: To develop test methods, nomenclature, definitions, classifications, recommended practices, instrumental standards and specifications for: 1) artists' paints, 2) components thereof, and 3) related materials used by artists.

Task Groups: .02: Lightfastness of Pigments, A. Rauch .04: Specifications for Artists' Paints, B. Bethel .07: Physical Properties, R. Gamblin .08: Toxicity Labeling, W. Stopford .09: Watercolors, D. Pyle .10: Consumer Evaluation, J. T. Luke .11: Gouache Paints, T. Takigawa .12: Determination of Toxicity, W. Stopford .14: Colored Pencils, R. Farfan .15: Pastels, V. Elliott

D01.61 on Paint Application Tools

Chairman: F. Burns

Scope: To develop test methods, nomenclature, definitions and recommended practices (including use) for paint application tools, and components thereof, used for on-site application of coatings by contact transfer to a surface.

Task Groups: .01: Paint Brushes, T. J. Sliva .02: Paint Rollers, D. Punches .03: Knitted Paint Applicator Fabrics, K. Gassen .04: Definitions & Nomenclature, D. Kaminski .05: Bulk Density of Filaments and Bristles, J. Feathers .06: Buckling Resistance of Filaments, J. Marler .07: Brush Filament Curl, B. Martin .08: Pole Warning Label, G. Leisure

11 ASTM Committee D-1 Policy

A. Preference of Units in D-1 Standards: Preference to metric units (SI) shall precede acceptable customary units in all cases where used. Customary units are acceptable but metric units are preferred. (For reference see Section H of the Form and Style for ASTM Standards Manual.

B. Recommended Editorial Practice for Chemical Calculation

1. To promote standardization in ASTM Methods of Test, the following symbols shall be used in chemical calculations:

a. B=Blank Determination D=Density or Specific Gravity N=Normality P=Precipitate Weight R=Residue Weight S=Sample Weight W =Other Weights V=Volume of Titrant in Actual Determination

b. Symbol for equivalents of solutions shall not be used relate to the material involved, e.g., Z for Zinc, M for Manganese, C for Calcium, etc.

c. The derivation of numerical factors used in calculations shall be explained simply; e.g., (Developed by Subcommittee D01.18, H. E. Ashton, Chairman, 1/26/73)

2. The same symbol shall not be used for different items the same standard without distinguishing subscripts. Different symbols shall not be used for the same item in the same standard.

C. Rating System: To promote uniformity in ASTM Methods of Test, the following scale shall be used for rating all subjective evaluations: RATING OR SCORE* PERFORMANCE OR PROPERTY** EFFECT OR CHANGE*** 10 Perfect None 8 Very Good Trace 6 Good Slight 4 Fair Moderate 2 Poor Severe 0 No Complete Failure * When the precision of the method allows better definition than the six ratings above, odd numbers may be added between the even numbers. The additional precision expected should be statistically verified before adding additional ratings. These rating numbers may not correspond to earlier methods which have arbitrary numbers assigned to certain levels of failure. ** e.g., Adhesion or Corrosion Resistance. *** e.g., Chalking or Color Change

D. Standard Conditions See D 3924, Specification for Standard Environment for Conditioning and Testing Paint, Varnish, Lacquer, and Related Materials.

E. Interlaboratory Testing See E 691, Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method.

F. Terminology The primary source of definitions of terms used in standards under the control of D01 shall be D 16, Terminology for Paint, Related Coatings, Materials, and Applications. For usage limited to a subcommittee or a technical standard, more specialized terms and definitions may be provided in the subcommittee terminology standard, or the terminology section of the standard.

12