printlux PVC eco wp rev adh Technical Information General Information Glossy, white, cadmium free, monomer plasticised vinyl, coated on one side with a solvent-free, age-resistant and permanently elastic acrylate adhesive. The other side is equipped with a waterproof, high quality topcoating to be used in the ink-jet process with a wide range of printers and inks. The coating is optimized for rapid drying, high ink anchoring, excellent image quality and it shows high flexibility. Dye-based as well as pigmented inks (indoor and outdoor types) are applicable. Good results were obtained for example with Encad GO inks and Hewlett Packard outdoor inks (1892), both series pigment based. Before printing large scale runs, check the compatibility of the product with your printing equipment. Areas of application / Handling printlux® PVC eco adhesive wp is a pliable and ink jet printable vinyl. It must always be printed on the side winded to the outside, equipped with a special coating to ensure an effective uptake of different inks. This leads to fast drying and low ink consumption with nearly all commercially available pigmented and dye based inks. To obtain best results, software, the type and the amount of ink have to be adapted and optimized. For protection and finishing of the prints, Neschen cold laminating films are highly recommended. For longer term outdoor application, edges and drill holes have to be sealed by clear outdoor lacquers. In this case the print is protected not only from intrusion of water and mechanical distortions, but also from deterioration by UV light. Printability is to be evaluated prior to large scale use as the number of variables (temperature, humidity, inks, software, printer, printing technology...) as well as their influences can be enormous. The printed film can be affixed over uneven or corrugated surfaces without brittling of the coating. The reversible adhesive allows removing of the adhesion even after mid-term Applications. Residual adhesive, which might occur under some special conditions can very easily be removed by usage of Petrolether (b.p. 60°-90°C / 140° -194°F). Technical Data

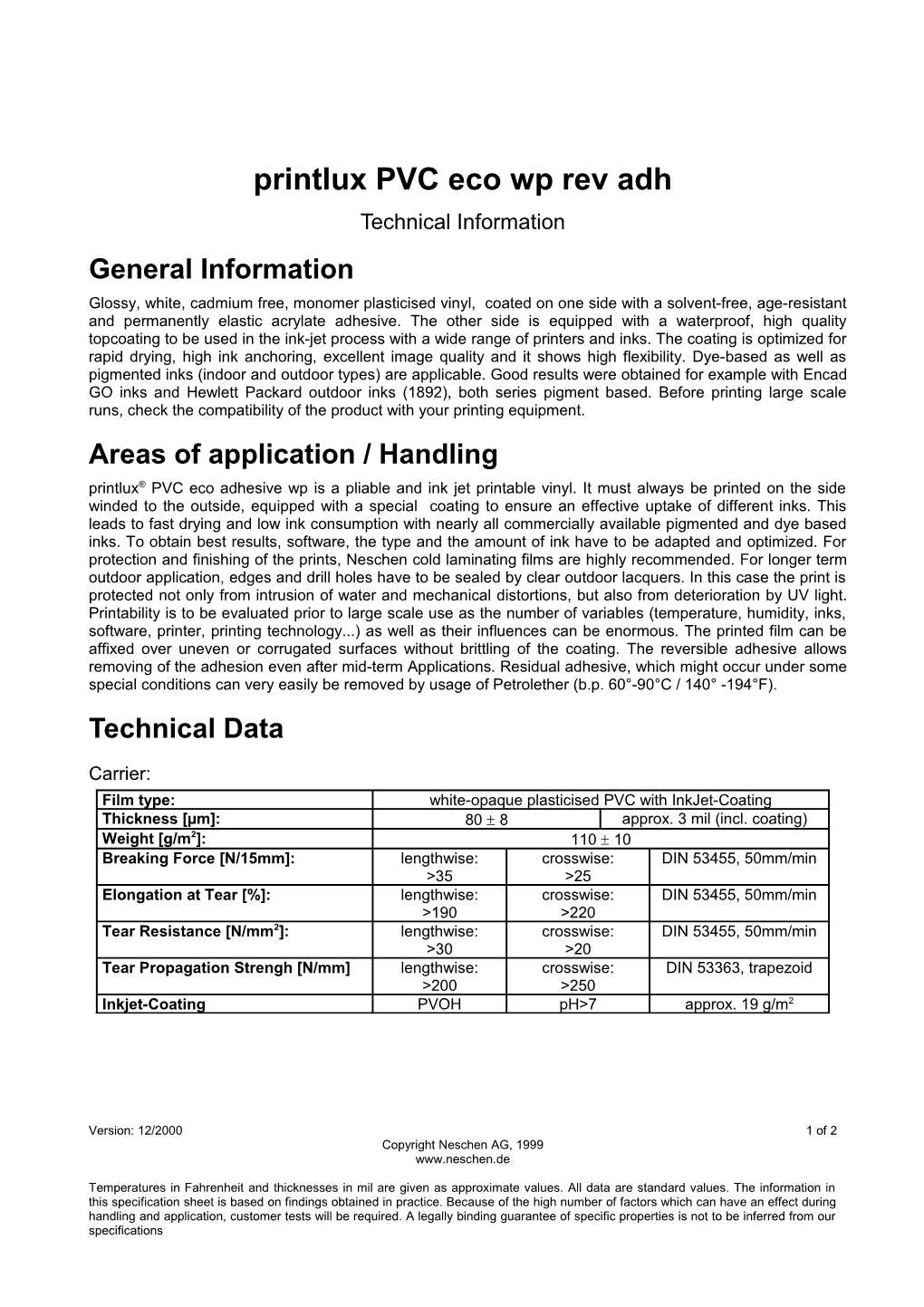

Carrier: Film type: white-opaque plasticised PVC with InkJet-Coating Thickness [µm]: 80 8 approx. 3 mil (incl. coating) Weight [g/m2]: 110 10 Breaking Force [N/15mm]: lengthwise: crosswise: DIN 53455, 50mm/min >35 >25 Elongation at Tear [%]: lengthwise: crosswise: DIN 53455, 50mm/min >190 >220 Tear Resistance [N/mm2]: lengthwise: crosswise: DIN 53455, 50mm/min >30 >20 Tear Propagation Strengh [N/mm] lengthwise: crosswise: DIN 53363, trapezoid >200 >250 Inkjet-Coating PVOH pH>7 approx. 19 g/m2

Version: 12/2000 1 of 2 Copyright Neschen AG, 1999 www.neschen.de

Temperatures in Fahrenheit and thicknesses in mil are given as approximate values. All data are standard values. The information in this specification sheet is based on findings obtained in practice. Because of the high number of factors which can have an effect during handling and application, customer tests will be required. A legally binding guarantee of specific properties is not to be inferred from our specifications printlux PVC eco wp rev adh Technical Information Adhesive: Adhesive Type: Waterbased Polyacrylate Dispersion PH-value: approx. 7 Weight [g/m2]: 20 2 Adhesive Strength[N/25 mm]: 10 min: >0,2 24h: >0,2 AFERA 4001 Masking: Type: white Kraft paper, siliconised on one side Thickness [µm]: 132 4 aprox. 5 mil Weight [g/m2]: 138 4 Removal Force [mN/cm] 10 – 65 speed 300 mm/min Others Handling/Storage Conditions: 18° to 25°C / 60° to 80° F; 40-60% relative humidity Shelf Life [Years]: 1 Temperatur Stability: -30°C to +50°C -20°F to +120°F affixed to aluminium Humid Climate Stability: no change 2 weeks affixed to aluminium at 40°C [change/no change] and 95% rel. humidity

All tests were performed in a normal climate in accordance with 23/50-2, DIN 50014.

Version: 12/2000 2 of 2 Copyright Neschen AG, 1999 www.neschen.de

Temperatures in Fahrenheit and thicknesses in mil are given as approximate values. All data are standard values. The information in this specification sheet is based on findings obtained in practice. Because of the high number of factors which can have an effect during handling and application, customer tests will be required. A legally binding guarantee of specific properties is not to be inferred from our specifications