Homework Solutions– Chapter 8

1. P-charts are used to monitor the process for attribute data. These are typically binomial “go, no-go” data. An example of a P-chart is percent of pieces nonconforming. X charts are used for charting population values for continuous measurement. X charts operate effectively with smaller sample sizes than P- charts, but it is more involved to analyze the sample for an X chart since a measurement must be taken. A rule of thumb for the sample size of a P-chart is to have at least one defective in each sample. This can require a relatively large sample size in some cases. If the process is slow, an X chart will generally be a better choice since it functions with smaller sample sizes. An example of an X chart is average time to complete a mile run for one person. R charts are used to compute process ranges for variable data, and are generally used in concert with X charts.

2. Before the agreement was made, the customer probably inspected each part to protect against off-spec supplies. This agreement (ideally) eliminates the need for this inspection. Appraisal costs, such as materials and supplies inspection and reliability testing, will be reduced since the agreement would ensure that the supplies are totally within tolerance. This allows the customer to focus attention on quality improvement within his or her own processes, requiring an increase in prevention cost. Scrap and rework costs will initially drop because of the improvement in the quality of the part supply. Once prevention programs are in force, scrap, repair, rework, and downtime costs will drop even further because of improvements in the internal process. External failure costs will drop because of improvement in the product and the process.

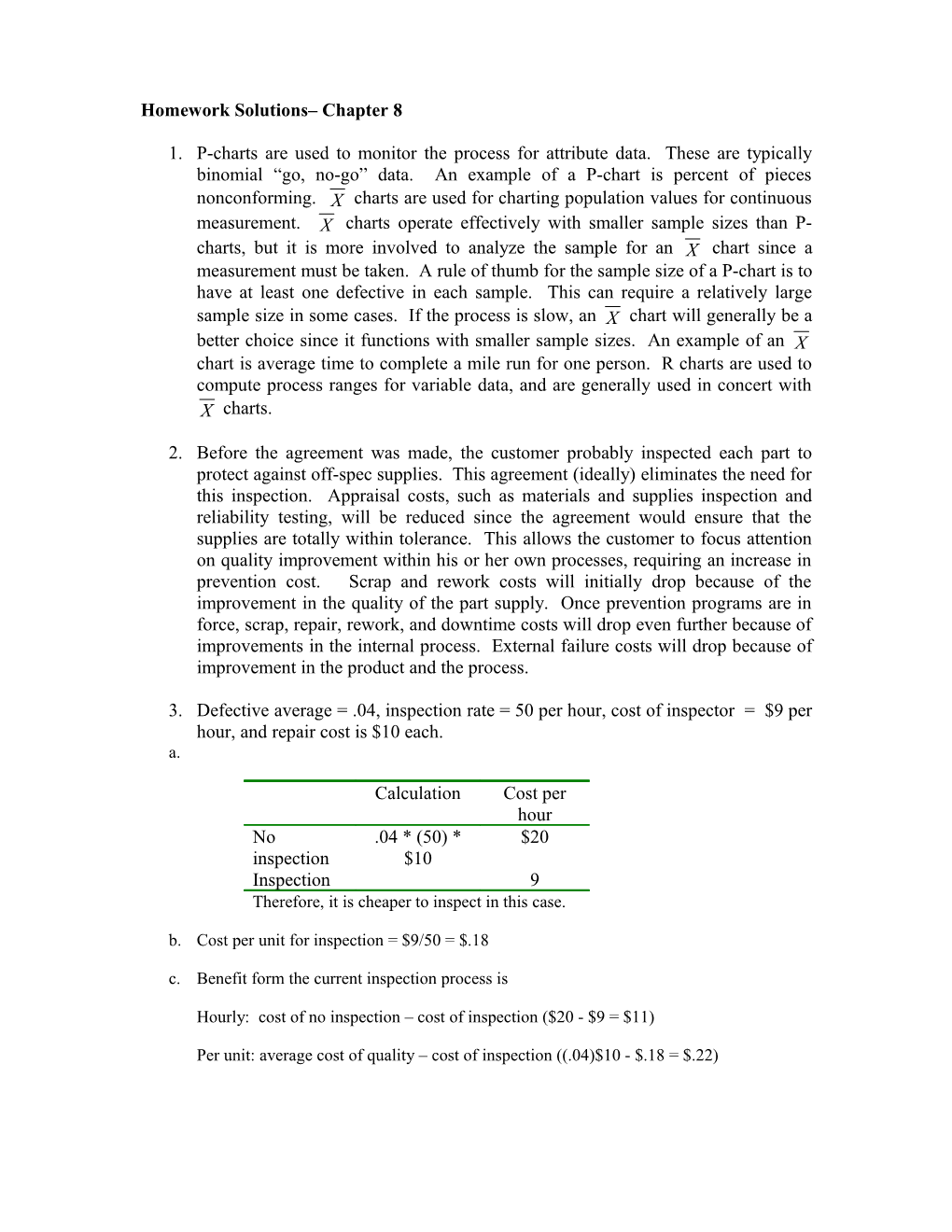

3. Defective average = .04, inspection rate = 50 per hour, cost of inspector = $9 per hour, and repair cost is $10 each. a.

Calculation Cost per hour No .04 * (50) * $20 inspection $10 Inspection 9 Therefore, it is cheaper to inspect in this case.

b. Cost per unit for inspection = $9/50 = $.18

c. Benefit form the current inspection process is

Hourly: cost of no inspection – cost of inspection ($20 - $9 = $11)

Per unit: average cost of quality – cost of inspection ((.04)$10 - $.18 = $.22) 4. UTL X X LTL 1.011.002 1.002 .99 C pk min , min , min.889,1.333 3 3 3(.003) 3(.003) = .889

b. The process is not capable at the 3 level. Because the process is consistent, if its mean was equal to the target value, then it would be capable at this level.

5. a. Ten defectives were found in 10 samples of size 15.

10 P = .067 10(15)

P(1 P) .067(1.067) S = .0645 p n 15

UCL = P + 1.96 S p = .067 + 1.96(.0645) = .194

LCL = P - 1.96 S p = .067 - 1.96(.0645) = -.060 zero

b. Stop the process and look for the special cause, it is out of statistical control. 6.

Sample 1 2 3 4 mean range 1 1010 991 985 986 993.00 25 2 995 996 1009 994 998.50 15 3 990 1003 1015 1008 1004.00 25 4 1015 1020 1009 998 1010.50 22 5 1013 1019 1005 993 1007.50 26 6 994 1001 994 1005 998.50 11 7 989 992 982 1020 995.75 38 8 1001 986 996 996 994.75 15 9 1006 989 1005 1007 1001.75 18 10 992 1007 1006 979 996.00 28 11 996 1006 997 989 997.00 17 12 1019 996 991 1011 1004.25 28 13 981 991 989 1003 991.00 22 14 999 993 988 984 991.00 15 15 1013 1002 1005 992 1003.00 21

X 999.1, R = 21.733

Control limits for X-bar chart:

UCL, LCL = , = 999.1 + .73(21.733) = 1014.965, 983.235 X A2 R

Control limits for R chart:

UCL = D4 R = 2.28(21.7333) = 49.551

LCL = D3 R = 0(21.7333) = 0.00 The process is in statistical control.