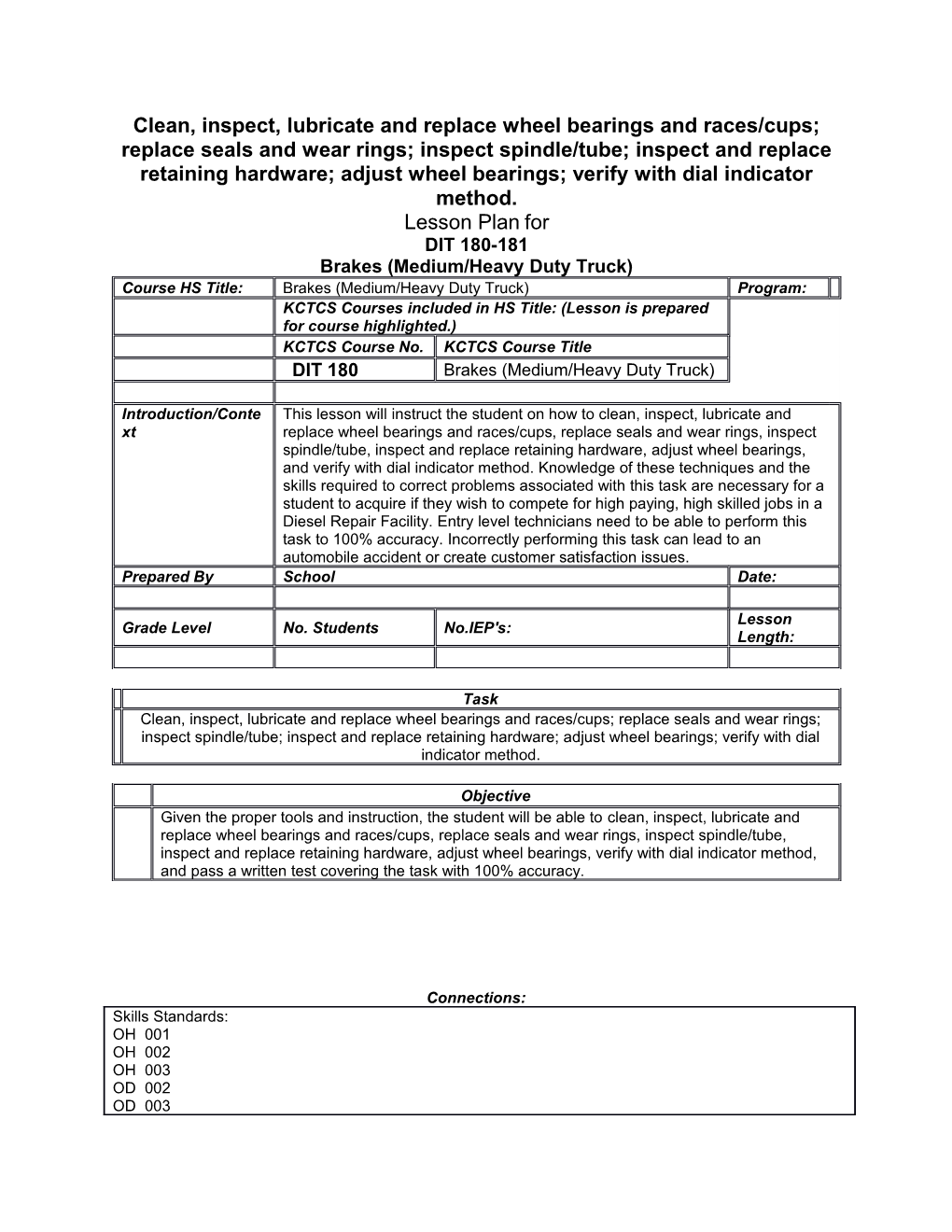

Clean, inspect, lubricate and replace wheel bearings and races/cups; replace seals and wear rings; inspect spindle/tube; inspect and replace retaining hardware; adjust wheel bearings; verify with dial indicator method. Lesson Plan for DIT 180-181 Brakes (Medium/Heavy Duty Truck) Course HS Title: Brakes (Medium/Heavy Duty Truck) Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title DIT 180 Brakes (Medium/Heavy Duty Truck)

Introduction/Conte This lesson will instruct the student on how to clean, inspect, lubricate and xt replace wheel bearings and races/cups, replace seals and wear rings, inspect spindle/tube, inspect and replace retaining hardware, adjust wheel bearings, and verify with dial indicator method. Knowledge of these techniques and the skills required to correct problems associated with this task are necessary for a student to acquire if they wish to compete for high paying, high skilled jobs in a Diesel Repair Facility. Entry level technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task can lead to an automobile accident or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Clean, inspect, lubricate and replace wheel bearings and races/cups; replace seals and wear rings; inspect spindle/tube; inspect and replace retaining hardware; adjust wheel bearings; verify with dial indicator method.

Objective Given the proper tools and instruction, the student will be able to clean, inspect, lubricate and replace wheel bearings and races/cups, replace seals and wear rings, inspect spindle/tube, inspect and replace retaining hardware, adjust wheel bearings, verify with dial indicator method, and pass a written test covering the task with 100% accuracy.

Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 Common Core Technical Standards: TD-OPS.2 TD-SYS.2 New Common Core State Standards: RST 11-12 3 RST 11-12 2 N-Q-3 N-Q-1 New Generation Science Standards: HS-PS2-1. HS-PS3-3.

INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts

Textbooks and Workbooks Editio Publish Page Author Title/ISBN No. n er s Various Brakes Medium/Heavy Duty Truck ASE Test Prep T4 Fifth Delmar 41 Bennett/Norma Heavy Duty Truck Systems Fourth Delmar 873 n

Equipment Quantity Item Source As Needed Dial Indicator Various

Content/Presentation/Demonstration Outline Instruct students that bearings are designed to provide long life, but premature bearing failure has many causes. If a bearing fails, the student must determine whether the failure was caused by normal wear or if the bearing failed prematurely. Inform students that premature bearing failure may be caused by lack of lubrication, improper type of lubrication, incorrect bearing adjustment, misalignment of related components such as shafts or housings, excessive bearing load, improper installation or service procedures, excessive heat, and dirt or contamination. Tell students that they should clean all bearings, bearing races, and hub assemblies with clean solvent and dry with compressed air. Next, have them perform a visual inspection on bearings and race (cone) assemblies. They should inspect units for wear, contamination, or overheat conditions (i.e., chrome surface worn away, blue color, pitting), bearing cage damage, or other abnormal defects. Instruct them to inspect the bearing and seal mounting surfaces on the spindle. Tell them that small metal burrs may be removed with a line-toothed file. Seal contact areas can become pitted or worn beyond a useful condition. Explain that in most cases there are replacement repair sleeves available to compensate for this. Tell students to install new components if original units are deemed unserviceable according to manufacturer recommendations and procedures. Let them know that most bearing replacement is necessary due to contamination. Explain that this can be caused by fluid loss due to seal failure possibly caused by improper bearing preload. Remind them to perform wheel bearing adjustments as per manufacturer’s recommended procedures. Have students check for acceptable endplay. Instruct students that a dial indicator should be attached to the hub or brake drum with its magnetic base. Tell them to adjust the dial indicator so that its plunger is against the end of the spindle with its line of action approximately parallel to the axis of the spindle. They should grasp the wheel or hub assembly at the three o’clock and nine o’clock positions. Push and pull the wheel-end assembly in and out while oscillating the wheel approximately 45 degrees. Tell them to stop oscillating the hub so that the dial indicator tip is in the same position as it was before oscillation began, then have them read the bearing endplay as the total indicator movement. Acceptable endplay is 0.001—0.005 inch.

Applications/Practice 1 Refer to content

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)