Commissioning plan for the AMO instrument, no light check out procedure

Ver 0.1 Christoph Bostedt First draft

Ver 0.2 Christoph Bostedt Incorporated changes in beamline controls from JDB, July 15th 2009

The AMO instrument consists of various independent components. Going downstream these are the single pulse shutter and slit system (SAS), the KB refocusing mirror system (KBO), the high field physics chamber (HFP) and the diagnostics chamber (DIA). In particular the mirror system (KBO) and the downstream chambers (HFP, DIA) require significant motion to accommodate for the two operating conditions with focused and unfocussed beam.

The commissioning of the AMO will be done in the following steps with increasing complexity: 1) Mechanical integrity of the system including motion and sensors 2) Vacuum check of each independent volume 3) Test of detectors and gas jet performance

1) Mechanical integrity of the system

The goal of the first commissioning step is to test the mechanical components of the system including motors, hardstops, and sensors. There will be a visual check that the controls drive the proper motors, that the motor stop sensors signal, that no collisions occur between the driving components, that there is no bending of the bellows beyond the acceptable limits, and that the motor are set to adequate speeds.

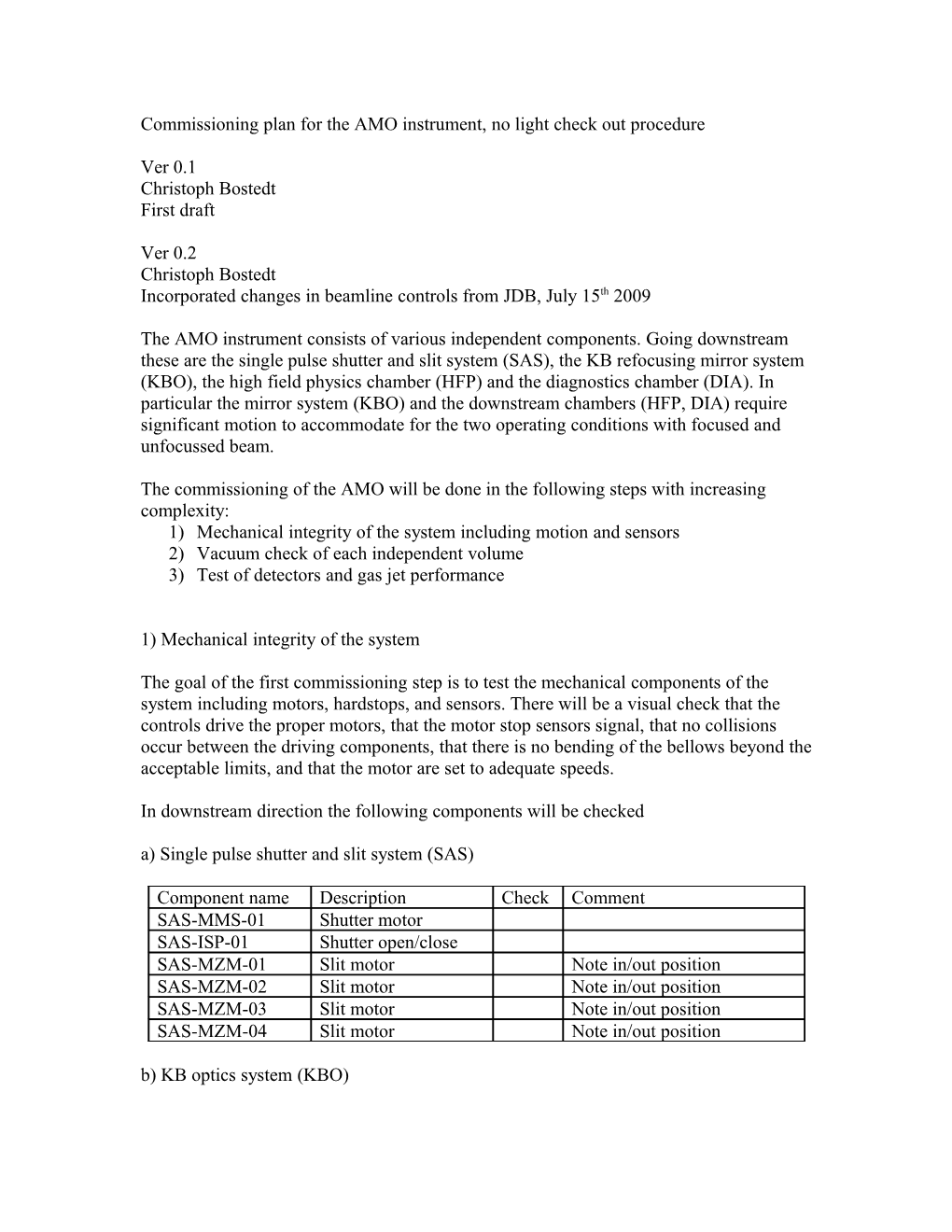

In downstream direction the following components will be checked a) Single pulse shutter and slit system (SAS)

Component name Description Check Comment SAS-MMS-01 Shutter motor SAS-ISP-01 Shutter open/close SAS-MZM-01 Slit motor Note in/out position SAS-MZM-02 Slit motor Note in/out position SAS-MZM-03 Slit motor Note in/out position SAS-MZM-04 Slit motor Note in/out position b) KB optics system (KBO) Component name Description Check Comment KBO-SPS-01..-12 Bellows limit sensors KB stand motors KBO-MMS-01,02 upstream KBO-MMS- KB stand motors 03,04,05 downstream KBO-STI-01 Tilt sensor KBO-MMS-11,12 Mirror bender KBO-MMS-13,14 Mirror bender c) High field physics chamber

Component name Description Check Comment HFP-SPS-01-..12 Bellows limit sensors HFP-MMS- HFP stand motors 01,02,03 upstream HFP-MMS- KB stand motors 04,05,06 downstream HFP-STI-01 Tilt sensor HFP-MMS-11,12 Etof 1 Motors Note center position HFP-MMS-21,22 Etof 2 Motors Note center position HFP-MMS-31,32 Etof 3 Motors Note center position HFP-MMS-41,42 Etof 4 Motors Note center position HFP-MMS-51,52 Etof 5 Motors Note center position Beam focus paddle HFP-MMS-61..-63 Note in/out position motors Beam view paddle HFP-MPA-01 pneumatic actuator Beam stop pneumatic HFP-MPA-02 actuator HFP-MMS-71..-73 Gas jet motors Note center position d) Diagnostics chamber

Component name Description Check Comment DIA-SPS-01-..12 Bellows limit sensors DIA-MMS- HFP stand motors 01,02,03 upstream DIA-MMS- KB stand motors 04,05,06 downstream DIA-STI-01 Tilt sensor DIA-MMS- Gas needle motors Note center position 11,12,13 DIA-MMS- Magnet motors Note center position 21,22,23 DIA-MMS- Hires beam screen Note in/out position 31,32,33 motors DIA-MMS- Hires beam screen Note in/out position 41,42,43 motors

After all motors and limit switches have been confirmed to work the KBO, HFP, and DIA chambers should be aligned to their optimal direct beam and focused beam position and the motor / encoder positions should be noted: e) Encoder steps for direct beam:

Component name Description Check Encoder KB stand motor 1 KBO-MMS-01 upstream KB stand motor 2 KBO-MMS-02 upstream KB stand motor 3 KBO-MMS-03 upstream KB stand motor 4 KBO-MMS-04 downstream KB stand motor 5 KBO-MMS-05 downstream KB stand motor 6 KBO-MMS-06 downstream

Component name Description Check Encoder HFP stand motor 1 HFP-MMS-01 upstream HFP stand motor 2 HFP-MMS-02 upstream HFP stand motor 3 HFP-MMS-03 upstream HFP stand motor 4 HFP-MMS-04 downstream HFP stand motor 5 HFP-MMS-05 downstream HFP stand motor 6 HFP-MMS-06 downstream

Component name Description Check Encoder DIA stand motor 1 DIA-MMS-01 upstream DIA stand motor 2 DIA-MMS-02 upstream DIA stand motor 3 DIA-MMS-03 upstream DIA stand motor 4 DIA-MMS-04 downstream DIA stand motor 5 DIA-MMS-05 downstream DIA stand motor 6 DIA-MMS-06 downstream f) Encoder steps for focused beam:

Component name Description Check Encoder KB stand motor 1 KBO-MMS-01 upstream KB stand motor 2 KBO-MMS-02 upstream KB stand motor 3 KBO-MMS-03 upstream KB stand motor 4 KBO-MMS-04 downstream KB stand motor 5 KBO-MMS-05 downstream KB stand motor 6 KBO-MMS-06 downstream

Component name Description Check Encoder HFP stand motor 1 HFP-MMS-01 upstream HFP stand motor 2 HFP-MMS-02 upstream HFP stand motor 3 HFP-MMS-03 upstream HFP stand motor 4 HFP-MMS-04 downstream HFP stand motor 5 HFP-MMS-05 downstream HFP stand motor 6 HFP-MMS-06 downstream

Component name Description Check Encoder DIA stand motor 1 DIA-MMS-01 upstream DIA stand motor 2 DIA-MMS-02 upstream DIA stand motor 3 DIA-MMS-03 upstream DIA-MMS-04 DIA stand motor 4 downstream DIA stand motor 5 DIA-MMS-05 downstream DIA stand motor 6 DIA-MMS-06 downstream 2) Vacuum check out a) Pump down and leak check

The first three chambers are rather simple from a vacuum point of view. They are all initially pumped down with a external pump stand through a manually operated valve and then they are pumped with ion pumps only. These three chambers are virtually always under vacuum.

Chamber Pumped Leak checked Ion pump running / current Comment SAS SAS-PIP-01 SAS SAS-PIP-02 KBO KBO-PIP-01 KBO KBO-PTS-01 fired Ti subl. pump

The HFP chamber is rather complicated from a vacuum point of view. It is pumped by many independent turbo pumps of which most of them have also an independent pre- vacuum system. For proper operation of this chamber many valves have to open and close following a specific logic described in DOCUMENT VACUUM LOGIC. The pump down procedure should be logged for the first time making sure the logic is implemented correctly.

Status (open/ Component name Description Comment start/ etc) HFP-PMF-01..-02 Roughing pumps Running?

HFP-GTC-01 ppre-PTM01 pressure

HFP-GTC-02 ppre-PTM02 pressure HFP-VIC-02 Valve prevac pump Open? HFP-VIC-03 Valve prevac pump Closed? Check vacuum START procedure Procedure followed? logic document HFP-GTC-01 Pressure 1 min HFP-GCC-01 Pressure 1 min HFP-GTC-01 Pressure 5 min HFP-GCC-01 Pressure 5 min HFP-GTC-01 Pressure 10 min HFP-GCC-01 Pressure 10 min

The gas jet chamber is an integral part of the high field physics experiment but can be considered an independent vacuum system. For proper operation of this chamber many valves have to open and close following a specific logic described in DOCUMENT VACUUM LOGIC. The pump down procedure should be logged for the first time making sure the logic is implemented correctly.

Status (open/ Component name Description Comment start/ etc) HFP-PMF-3 Roughing pumps Running?

HFP-GTC-03 ppre-PTM01 pressure HFP-VIC-06 Valve prevac pump Open? HFP-VIC-07 Valve prevac pump Closed? Check vacuum START procedure Procedure followed? logic document HFP-GTC-03 Pressure 1 min HFP-GCC-03 Pressure 1 min HFP-GTC-03 Pressure 5 min HFP-GCC-03 Pressure 5 min HFP-GTC-03 Pressure 10 min HFP-GCC-03 Pressure 10 min

Similar to the HFP chamber, the DIA is rather complicated from a vacuum point of view. It is pumped by many independent turbo pumps of which most of them have also an independent pre-vacuum system. For proper operation of this chamber many valves have to open and close following a specific logic described in DOCUMENT VACUUM LOGIC. The pump down procedure should be logged for the first time making sure the logic is implemented correctly.

Status (open/ Component name Description Comment start/ etc) DIA-PMF-01..-02 Roughing pumps Running? DIA-PMF-05 Roughing pumps Running?

HFP-GTC-01 ppre-PTM01 pressure

HFP-GTC-02 ppre-PTM02 pressure

HFP-GTC-05 ppre-PTM01 pressure HFP-VIC-02 Valve prevac pump Open? HFP-VIC-03 Valve prevac pump Closed? Check vacuum START procedure Procedure followed? logic document DIA-GTC-01 Pressure 1 min DIA-GCC-01 Pressure 1 min DIA-GCC-10 Pressure 1 min DIA-GTC-01 Pressure 5 min DIA-GTC-01 Pressure 5 min DIA-GCC-10 Pressure 5 min DIA-GTC-01 Pressure 10 min DIA-GCC-01 Pressure 10 min DIA-GCC-10 Pressure 10 min Last not least all chambers should be leak checked and a RGA scan from the HFP and DIA should be taken and archived.

Status (open/ System Description Comment start/ etc) SAS chamber Leak rate Mbar l / sec SAS chamber Ultimate pressure KBO chamber Leak rate Mbar l / sec KBO chamber Ultimate pressure HFP main chamber Leak rate Mbar l / sec HFP main chamber Ultimate pressure HFP main chamber RGA spectrum HFP jet chamber Leak rate Mbar l / sec HFP jet chamber Ultimate pressure DIA chamber Leak rate Mbar l / sec DIA chamber Ultimate pressure DIA chamber RGA spectrum b) Venting procedure

The SAS and KBO systems will always stay under vacuum and only vented manually if needed. The HFP and DIA systems may be vented on a more regular basis and stop/ venting procedures have been implemented as described in the DOCUMENT “VACUUM LOGIC”. The stop/ venting procedure should be logged for the first time to make sure that it has been implemented correctly.

Status (open/ System Description Comment start/ etc) HFP main chamber STOP procedure Procedure followed? HFP main chamber Vented (xxx min) Minutes? HFP jet chamber STOP procedure Procedure followed? HFP jet chamber Vented (xxx min) Minutes? DIA chamber STOP procedure Procedure followed? DIA chamber Vented (xxx min) Minutes? c) Gate valve operation

All gate valves should be operated and their positions confirmed while the whole system is under vacuum. In coordination with the LCLS control room the two modes for “emergency close” and “controlled close” should be checked for each gate valve as described in the DOCUMENT “VACUUM LOGIC”. Open / close Component name Description Comment correct KBO-VGC-01 KBO upstream KBO-VGC-02 KBO downstream HFP-VGC-02 HFP downstream HFP-VGC-03 HFP jet chamber DAI-VGC-02 DIA upstream d) Interlocks

All interlocks as described in the DOCUMENT “VACUUM LOGIC” should be checked for each chamber.

Status (open/ System Description Comment start/ etc) SAS Pressure setpoints Correct? SAS System failure Interlock response ok? KBO Pressure setpoints Correct? KBO System failure Interlock response ok? HFP main Pressure setpoints Correct? HFP main System failure Interlock response ok? HFP jet Pressure setpoints Correct? HFP jet System failure Interlock response ok? DIA Pressure setpoints Correct? DIA System failure Interlock response ok?

3) Test of detectors and gas jet performance a) CCD cameras

During the light check out procedure it should be checked that all CCD cameras yield signal and that they are focused on the respective screen. The fast cameras for single shot images should be triggered with 120 Hz to make sure that the data transfer rates are sufficient.

Camera name Screen Status (ok) Comment SAS-CVV-01 Fast shutter KBO-CVV-01..-04 Mirror guards HFP-CVV-01 Entrance aperture HFP-CVV-02 Beam focus paddle HFP-CVV-03 Beam paddle HFP-CVD-01 Ion tof Fast camera DIA-CVV-01 Diff pump aperture DIA-CVV-02 Gas det. aperture DIA-CVV-10 Magnetic bottle DIA-CVD-01 Beam screen upstr. Fast camera DIA-CVD-02 Beam screen dwnst Fast camera b) electron tofs

Each of the electron tofs should go through a careful start up routine during which the voltages on the MCPs are ramped up slowly and the dark counts are monitored with an oscilloscope. Further, all acceleration / retarding voltages should be tested. The pressure in the HFP chamber read on HFP-GCC-01 should be at or below 1x10-7 Torr and the whole system should be at room temperature (i.e., not baking etc).

Etof1:

Voltage Screen Status (ok) Comment Cabling Check connections Ramp up in steps MCP <100 Volts / min Dark counts MCP Volts? appearing at Dark counts at full MCP Hz operating voltage Dark counts at full MCP mV operating voltage Ok? All other voltages Sparking?

Etof2:

Voltage Screen Status (ok) Comment Cabling Check connections Ramp up in steps MCP <100 Volts / min Dark counts MCP Volts? appearing at Dark counts at full MCP Hz operating voltage Dark counts at full MCP mV operating voltage Ok? All other voltages Sparking?

Etof3: Voltage Screen Status (ok) Comment Cabling Check connections Ramp up in steps MCP <100 Volts / min Dark counts MCP Volts? appearing at Dark counts at full MCP Hz operating voltage Dark counts at full MCP mV operating voltage Ok? All other voltages Sparking?

Etof4:

Voltage Screen Status (ok) Comment Cabling Check connections Ramp up in steps MCP <100 Volts / min Dark counts MCP Volts? appearing at Dark counts at full MCP Hz operating voltage Dark counts at full MCP mV operating voltage Ok? All other voltages Sparking?

Etof5:

Voltage Screen Status (ok) Comment Cabling Check connections Ramp up in steps MCP <100 Volts / min Dark counts MCP Volts? appearing at Dark counts at full MCP Hz operating voltage Dark counts at full MCP mV operating voltage Ok? All other voltages Sparking?

c) ion tof Similar to the electron tofs, the ion tof should go through a careful start up routine. The voltages on the MCPs should be ramped up even slower due to the large size and imaging needs of the MCP. Again, the dark counts should be monitored with an oscilloscope. Further, all acceleration / retarding voltages should be tested. The pressure in the HFP chamber read on HFP-GCC-01 should be at or below 1x10-7 Torr and the whole system should be at room temperature (i.e., not baking etc).

Voltage Screen Status (ok) Comment Cabling Check connections Ramp up in steps MCP <100 Volts/10 min Dark counts MCP Volts? appearing at Dark counts at full MCP Hz operating voltage Dark counts at full MCP mV operating voltage Ok? All other voltages Sparking? d) magnetic bottle spectrometer

The start up routine for the magnetic bottle spectrometer is very similar to the one of the electron tofs. In addition there is a coil for supplying a homogenous magnetic field along the drift tube.

Voltage Screen Status (ok) Comment Cabling Check connections Ramp up in steps MCP <100 Volts / min Dark counts MCP Volts? appearing at Dark counts at full MCP Hz operating voltage Dark counts at full MCP mV operating voltage Ok? All other voltages Sparking? Coil current Ok? Amps e) HFP gas jet The gas jet tests should be broken down into three steps. First all components of the gasinlet system should be tested and the gas lines should be pumped and purged. Then the gas jet should be fired and it should be tested how the vacuum system can handle the gas load. Lastly the gas jet should be aligned with the feedback coming from the HFP- GCC-01 gauge. All detectors should be off during the gas jet tests and the gate valves should be closed.

Status (ok, Component name Description reading, Comment running, etc.) HFP-PMF-04 Gasinlet pump HFP-VIC-08 Gasinlet valve Gasinlet pressure HFP-GMP-04 gauge Gasinlet system Pump and purge > 3x HFP-MMS-71-..73 Gasjet motors HFP-MZA-01 Gasjet actuator Expected operation: Gas jet chamber HFP-GCC-03 Pressure at … Hz, bar, pressure opening time Extreme operation: Gas jet chamber HFP-GCC-03 Pressure at … Hz, bar, pressure opening time Optimize position on HFP-MMS-71-..73 Gasjet motors HFP-GCC-01 Similar conditions as HFP-GCC-01 Gasjet optimized above for expected operations f) DIA gas needle

The gas needle is a rather simple gas delivery system and it should be mainly tested that all gasinlet system components work and that the system can handle the gas load.

Status (ok, Component name Description reading, Comment running, etc.) DIA-PMF-04 Gasinlet pump DIA-VIC-09 Gasinlet valve DAI-VCM-01 Gasinlet valve Gasinlet pressure HFP-GMP-04 gauge Gasinlet system Pump and purge > 3x DIA chamber DIA-GCC-01 Note valve setting pressure g) Gas detector inlets

Similar to the gas needle the Nitrogen supply for the gas detector is rather simple and it should be mainly tested that all gasinlet system components work and that the system can handle the gas load. Status (ok, Component name Description reading, Comment running, etc.) DIA-PMF-06 Gasinlet pump DIA-VIC-12 Gasinlet valve DIA-VCC-06 Gasinlet valve Gasinlet pressure HFP-GMP-06 gauge Gasinlet system Pump and purge > 3x DIA diff. pumping DIA-GCC-05 Note valve setting pressure DIA chamber DIA-GCC-01 Note valve setting pressure