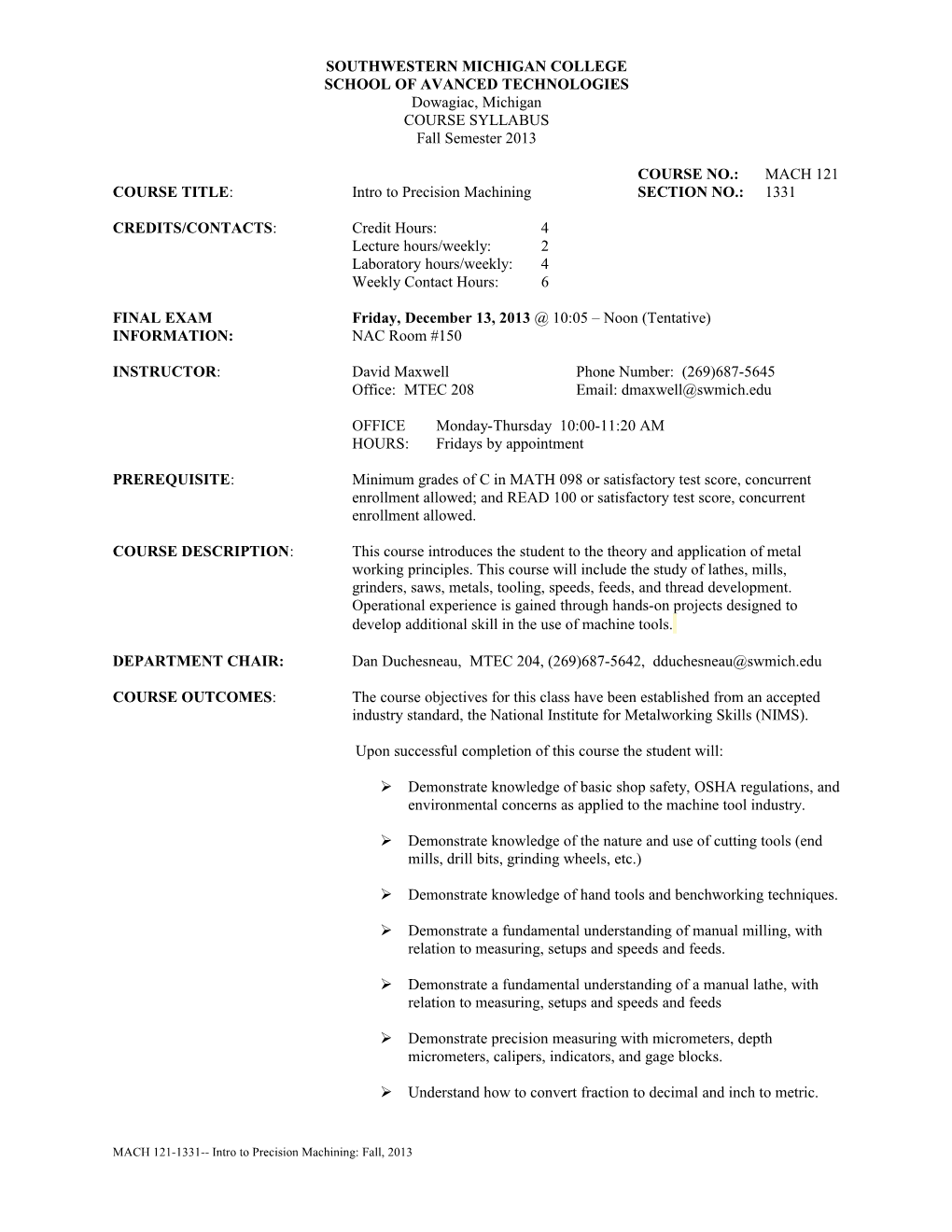

SOUTHWESTERN MICHIGAN COLLEGE SCHOOL OF AVANCED TECHNOLOGIES Dowagiac, Michigan COURSE SYLLABUS Fall Semester 2013

COURSE NO.: MACH 121 COURSE TITLE: Intro to Precision Machining SECTION NO.: 1331

CREDITS/CONTACTS: Credit Hours: 4 Lecture hours/weekly: 2 Laboratory hours/weekly: 4 Weekly Contact Hours: 6

FINAL EXAM Friday, December 13, 2013 @ 10:05 – Noon (Tentative) INFORMATION: NAC Room #150

INSTRUCTOR: David Maxwell Phone Number: (269)687-5645 Office: MTEC 208 Email: [email protected]

OFFICE Monday-Thursday 10:00-11:20 AM HOURS: Fridays by appointment

PREREQUISITE: Minimum grades of C in MATH 098 or satisfactory test score, concurrent enrollment allowed; and READ 100 or satisfactory test score, concurrent enrollment allowed.

COURSE DESCRIPTION: This course introduces the student to the theory and application of metal working principles. This course will include the study of lathes, mills, grinders, saws, metals, tooling, speeds, feeds, and thread development. Operational experience is gained through hands-on projects designed to develop additional skill in the use of machine tools.

DEPARTMENT CHAIR: Dan Duchesneau, MTEC 204, (269)687-5642, [email protected]

COURSE OUTCOMES: The course objectives for this class have been established from an accepted industry standard, the National Institute for Metalworking Skills (NIMS).

Upon successful completion of this course the student will:

Demonstrate knowledge of basic shop safety, OSHA regulations, and environmental concerns as applied to the machine tool industry.

Demonstrate knowledge of the nature and use of cutting tools (end mills, drill bits, grinding wheels, etc.)

Demonstrate knowledge of hand tools and benchworking techniques.

Demonstrate a fundamental understanding of manual milling, with relation to measuring, setups and speeds and feeds.

Demonstrate a fundamental understanding of a manual lathe, with relation to measuring, setups and speeds and feeds

Demonstrate precision measuring with micrometers, depth micrometers, calipers, indicators, and gage blocks.

Understand how to convert fraction to decimal and inch to metric.

MACH 121-1331-- Intro to Precision Machining: Fall, 2013 TEXTBOOK: REQUIRED: Hoffman, Peter J., et. al. Precision Machining Technology Clifton Park, NY: Delmar/Cengage Learning, 2012

OPTIONAL: Erik Oberg [et. al] Machinery’s Handbook, 29th edition. Industrial Press, 2012

Lenzi, David and James Hillwig. Precision Machining Technology Workbook and Projects Manual Clifton Park, NY: Delmar/Cengage Learning, 2012 ADDITIONAL REQUIRED RESOURCES: MACH Materials Voucher Scientific Calculator (TI 36X Solar Preferred) METHOD OF INSTRUCTION: This course uses lecture, discussion, audio / visual materials, readings and lab projects.

EVALUATION METHOD: Student grades will be calculated and weighted as follows: Homework 25% Lab projects 30% Attendance 10% Quizzes 5% Midterm 10% Final Exam 20% Total 100%

GRADING SCALE: The following grading scale will be in effect for this course:

A 93.4-100% C 73.4-76.7%

A- 90-93.3% C- 70-73.3%

B+ 86.8-89.9% D+ 66.8-69.9%

B 83.4-86.7% D 63.4-66.7%

B- 80-83.3% D- 60-63.3%

C+ 76.8-79.9% F 0-59.9%

To satisfy Core Curriculum requirements, students must earn a grade of “C” or higher in this class.

ATTENDANCE POLICY: This coursed normally meets on Monday and Wednesday in NAC 150 or MTEC226 from 11:30-2:40. Attendance is mandatory, and will be recorded as per college policy. A tardy will receive half credit for that class. Any student more than 20 minutes tardy will be counted absent. Any work or assignments missed due to an unexcused absence will not be accepted.

TESTING POLICY: Students are expected to take all examinations as they are scheduled. Students who are ill must contact the instructor within one week of the original testing date. The instructor reserves the right to determine whether a make-up test will be given and the format of the testing method.

MACH 121-1331-- Intro to Precision Machining: Fall, 2013 FEEDBACK POLICY: Under normal circumstances, all class work (text questions, quizzes, exams, etc.) will be graded within seven days after submission. All grades will be posted on Moodle as items are evaluated.

Representative student work will be used as a part of SMC’s on-going NOTICE: curriculum assessment program.

OTHER COURSE 1. All assignments are due at the EXPECTATIONS: beginning of class. Late submissions will be penalizes 10% for each class period after the due date.

2. All students are to use SMC Wired, as emails and discussions may be online and needed for class. Only SMC email accounts will be used for this class.

3. Food and beverages are allowed in the classroom and lab at the instructor’s discretion.

4. Ethnic or gender specific comments or jokes, as well as crude or offensive language, will not be tolerated in the classroom, shop, or workplace. This includes, but is not limited to, clothing, stickers, etc. Lack of respect for other students, their property (including tools), or school property, will be dealt with in an appropriate manner. In addition, "Students are expected to assist in maintaining a classroom environment that is conducive to learning. In order to assure that all students have the opportunity to gain from time spent in class, students are prohibited from engaging in any form of distraction. Inappropriate behavior in the classroom shall result, minimally, in a request to leave class" (College Civility Policy) and may result in a Concerns Report being filed.

5. Internet usage on college property shall not violate Southwestern Michigan College’s Acceptable Use Policy.

6. A safe environment is to be observed at all times. ANSI Z87.1 approved safety glasses with clear lenses MUST be worn at all times in the shop.

7. Students will wear appropriate clothing in the shop at all times. Shorts, baggy clothing, open-toed shoes, certain types of jewelry, neckties, or any other items that could pose an unnecessary safety hazard is prohibited from the shop. Violations may result in being banned from the shop.

8. All students are expected to clean up after themselves and participate in keeping the shop clean.

9. Horseplay and unprofessional behavior is not allowed in the shop.

10. Use of personal electronic devices, including texting, while operating lab equipment is expressly prohibited. First offense: expulsion from the lab for the day. Second offense: expulsion from the class.

CLASSROOM BEHAVIOR: Students are expected to assist in maintaining a classroom environment that is

MACH 121-1331-- Intro to Precision Machining: Fall, 2013 conducive to learning. In order to assure that all students have the opportunity to gain from time spent in class; students are prohibited from engaging in any form of distraction. Inappropriate behavior in the classroom shall result, minimally, in a request to leave class.

ACCEPTABLE USE OF All phones, iPods, Blackberries, Palm Pilots, pagers, laptops and other PERSONAL technological devices including devices capable of taking photographs must COMMUNICATION be turned off or placed on vibrate mode and may not be brought out during TECHNOLOGY: class. If you are expecting or receiving an urgent call, you are required to leave the classroom before answering. Violation of this policy will result in your removal from the classroom for the class period. Multiple violations of this policy will be referred to the appropriate dean for disciplinary action. Further details or ramifications of violations may be found elsewhere in this syllabus. The instructor has the right to modify this policy to meet the needs of the course.

HONESTY POLICY: Cheating or plagiarizing will absolutely not be tolerated at Southwestern Michigan College. Any student found cheating or plagiarizing material in any manner may be assigned a failing semester/session grade in this course. A second such incident while at SMC could result in suspension or expulsion from the institution. A student found in violation of this section of the syllabus will not be allowed to drop this course. Additional detail regarding cheating and/or plagiarism may be found elsewhere in this syllabus. For more detailed information consult the SMC Code of Student Conduct.

NOTICE: Information in this syllabus was, to the best knowledge of the instructor, considered correct and complete when distributed for use at the beginning of the semester. The instructor, however, reserves the right, acting within the policies and procedures of Southwestern Michigan College, to make changes in course content or instructional techniques.

COURSE OUTLINE AND ASSIGNMENTS

Sep. 4: Section 1, Unit 1 – Introduction to Machining. Text questions #1-14, p. 19. Section 2, Unit 1 – Introduction to Safety. Text questions #1-17, p. 62. Due Sep. 9.

Sep. 9, 11: Safety Quiz – General Safety, Sep. 9 Section 2, Unit 2 – Measuring Systems and Math. Questions #1-9 p. 81. Due Sep. 11. Section 2, Unit 3 – Semi-Precision Measurement. Worksheet. Ques. #3-7, p. 96. Due Sep. 16. Section 2, Unit 4 – Precision Measurement. Worksheet. Ques. #2, 6-9, 14, 19, 21, p. 146. Due Sep. 16.

Sep. 16, 18: Section 3, Unit 2 – Layout. Ques. #1-11, p. 249. Due Sep. 18. Section 3, Unit 4 – Saws. Ques. #1-5, 7-19, p. 282. Due Sep. 23.

Sep. 23, 25: Safety Quiz – Saws, Sep. 25. Section 5, Unit 1 – Introduction to the Lathe. Ques. #1-9, p. 363. Due Sep. 30. Section 5, Unit 2 – Workholding & Toolholding for Lathe. Ques. #1-4, 6-7, 10-13, p. 384. Due Sep. 30.

Sep. 30, Oct. 2: Safety Quiz – Lathes, Oct. 2 Section 5, Unit 3 – Machining Operations on the Lathe. Ques. #1-19, p. 413-4. Due Oct. 7.

Oct. 7, 9: Section 4, Unit 1 – Introduction to the Drill Press. Ques. #1, 3, 4, 6, p. 318. Due Oct. 9. Section 4, Unit 2 – Tools, Toolholding, and Workholding for the Drill Press. Ques. #1-8, p. 334. Due Oct. 14 Section 4, Unit 3 – Drill Press Operations. Ques. #1-13, p. 351. Due Oct. 14.

Oct. 14, 16: Safety Quiz – Drilling Machines, Oct. 14. MID-TERM EXAM Oct. 16.

MACH 121-1331-- Intro to Precision Machining: Fall, 2013 Oct. 21, 23: Section 6, Unit 1 – Intro to the Vertical Milling Machine. Ques. #1-10, p. 463. Due Oct. 23. Section 6, Unit 2 – Mill Tools, Toolholding, & Workholding. Ques. #1-8, p. 480. Due Oct. 28. Section 6, Unit 3 – Vertical Milling Operations (Safety). Ques. #1, p. 519. Due Oct. 28.

Oct. 28, 30: Safety Quiz – Vertical Mills, Oct. 28. Section 6, Unit 3 – Vertical Milling Operations. Ques. #3-5, 7-14. Due Nov. 4.

Nov. 4, 6: Section 3, Unit 3 – Hand Tools. Ques. #1-17, p. 265. Due Nov. 11. Section 3, Unit 6 – Hand Drilling, Threading, Tapping, and Reaming. Ques. #2-10, p. 309. Due Nov. 11.

Nov. 11, 13: Section 3, Unit 5 – Offhand Grinding. Ques. #1-10, p. 292. Due Nov. 18. Section 2, Unit 8 – Maintenance, Lubrication, and Cutting Fluid Overview. All ques., p. 199. Due Nov. 18.

Nov. 18, 20: Safety Quiz – Offhand Grinding Nov. 18. Section 2, Unit 5 – Quality Assurance, Process Planning, and Quality Control. All ques., p. 156. Due Nov. 25.

Nov. 25, 27: Section 2, Unit 6 – Metal Composition and Classification. Ques. #1-9, p. 173. Due Dec. 2. Section 2, Unit 7 – Heat Treatment of Metals. Ques. #1-9, 13, p. 189. Due Dec. 2.

Dec. 2, 4: Section 1, Unit 2 – Careers in Machining. Ques. #3, 8-10, p. 27. Due Dec. 9. Section 1, Unit 3 – Workplace Skills. Ques. #6-8, 10-11, p. 40-41. Due Dec. 9.

Dec. 9: Review for Final Exam.

Dec. 13: FINAL EXAM – CUMULATIVE (10:05 – NOON) NILES AREA CAMPUS Room #150. (Time is subject to change.)

OTHER DATES Monday, Sept. 9 Last day to add classes. Friday, Sept. 13 Last to drop classes for 100% refund Friday, Oct. 11 Graduation applications for fall semester due Nov. 28-Dec. 1 Thanksgiving break

ERRATA

p. 146: Question 7 should refer to question 6, not question 11. p. 351: Question 10 should read 0.040”, not 0.40”.

BIBLIOGRAPHY

Fitzpatrick, Michael. Machining and CNC Technology. Boston MA: McGraw Hill, 2005

Harvey, James A. Machine Shop Trade Secrets. New York: Industrial Press Inc., 2004

Kibbe, Richard R., et al. Machine Tool Practices. 9th edition. Boston MA: Pearson Prentice Hall, 2010 (Former text for this class, excellent reference.)

Krar, Steve F., Arthur R. Gill, and Peter Smid. Technology of Machine Tools. 6th edition. Boston MA: McGraw Hill , 2005

Meyers, Arthur R. and Thonas J. Slattery. Basic Machining Reference Handbook. Second edition. New York: Industrial Press Inc., 2001

MACH 121-1331-- Intro to Precision Machining: Fall, 2013 Walker, John R. Exploring Metalworking. 5th edition. Tinley Park, IL: Goodhart-Wilcox Co., Inc., 2009

Walker, John R. Machining Fundalmentals. Tinley Park, IL: Goodhart-Wilcox Co., Inc., 2004

Walker, John R. Modern Metalworking. Tinley Park, IL: Goodhart-Wilcox Co., Inc., 2004 (High school text that covers the basics of machining and other metalworking as well.)

Wolfe, John H. and Everett R. Phelps. Practical Shop Mathematics. Two volumes. Forth edition. Lake Forest, IL: Glencoe/McGraw Hill, 1958, 1960 (Standard math text for machinist for years, the 2nd volume contains significant info on compound angles.)

In addition, many old machining books that are long out of print have some excellent material which is still relevant to the machinist, including a number of “old school” ideas that could offer some helpful insights.

MACH 121-1331-- Intro to Precision Machining: Fall, 2013