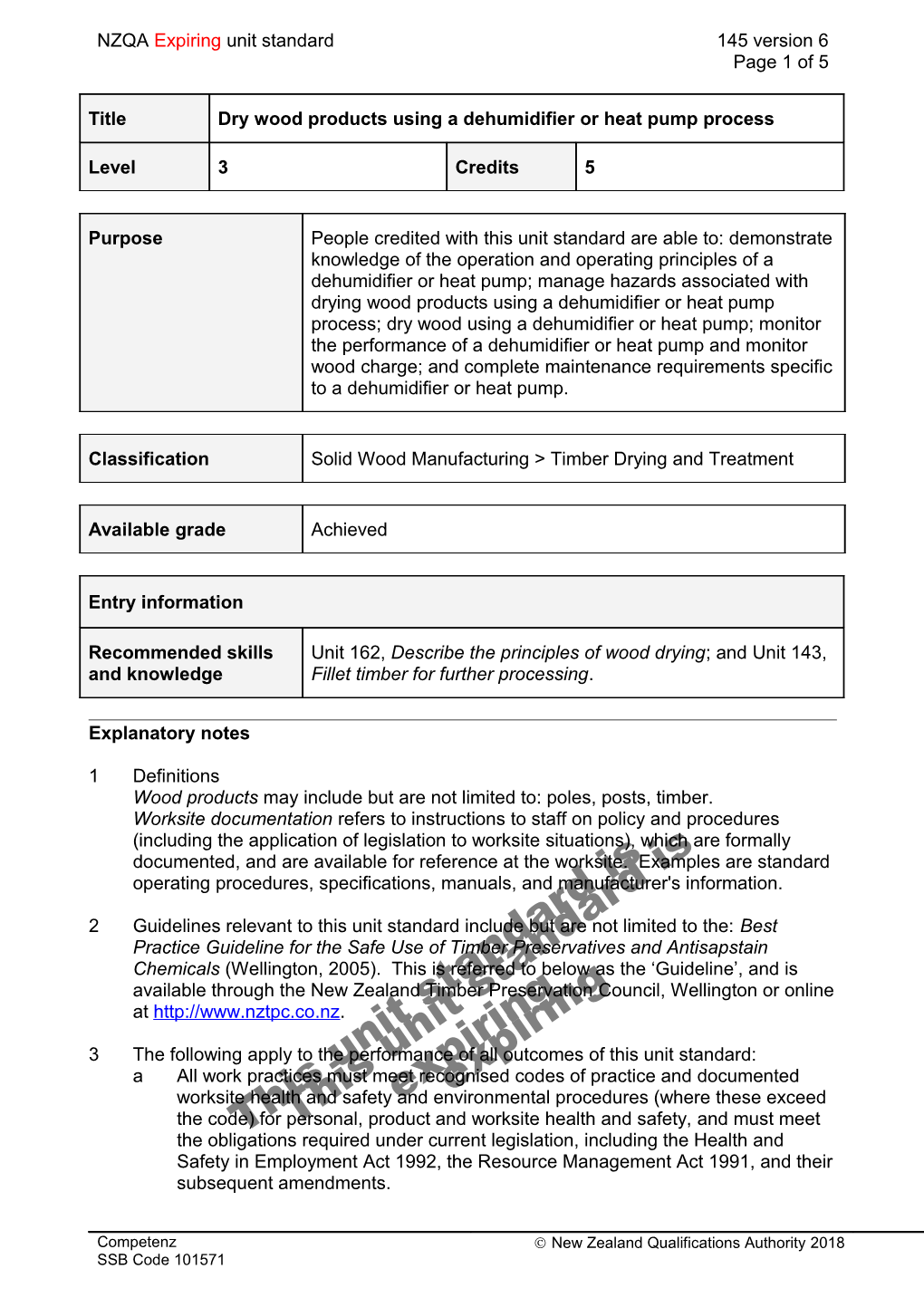

NZQA Expiring unit standard 145 version 6 Page 1 of 5

Title Dry wood products using a dehumidifier or heat pump process

Level 3 Credits 5

Purpose People credited with this unit standard are able to: demonstrate knowledge of the operation and operating principles of a dehumidifier or heat pump; manage hazards associated with drying wood products using a dehumidifier or heat pump process; dry wood using a dehumidifier or heat pump; monitor the performance of a dehumidifier or heat pump and monitor wood charge; and complete maintenance requirements specific to a dehumidifier or heat pump.

Classification Solid Wood Manufacturing > Timber Drying and Treatment

Available grade Achieved

Entry information

Recommended skills Unit 162, Describe the principles of wood drying; and Unit 143, and knowledge Fillet timber for further processing.

Explanatory notes

1 Definitions Wood products may include but are not limited to: poles, posts, timber. Worksite documentation refers to instructions to staff on policy and procedures (including the application of legislation to worksite situations), which are formally documented, and are available for reference at the worksite.s Examplesis are standard operating procedures, specifications, manuals, and manufacturer's id information. rd r 2 Guidelines relevant to this unit standard include buta areda not limited to the: Best Practice Guideline for the Safe Use of Timbern dPreservativesn and Antisapstain Chemicals (Wellington, 2005). This is referreda ta to below as the ‘Guideline’, and is available through the New Zealand sTimbert s Preservationg g Council, Wellington or online at http://www.nztpc.co.nz. t it in in i n ir ir 3 The following apply to theu performancen u p of all poutcomes of this unit standard: a All work practicess mustis meet recognisedxex codes of practice and documented worksite healthi andh safety ande environmental procedures (where these exceed the code) forh personal,T product and worksite health and safety, and must meet the obligationsT required under current legislation, including the Health and Safety in Employment Act 1992, the Resource Management Act 1991, and their subsequent amendments.

Competenz Ó New Zealand Qualifications Authority 2018 SSB Code 101571 NZQA Expiring unit standard 145 version 6 Page 2 of 5

b All work practices must meet documented worksite operating procedures. This includes the recording (by electronic or non-electronic means) of activities, events, and decisions. c All evidence of communications gathered in relation to this unit standard must be in accordance with worksite procedures for content, recipient, timing and method.

Outcomes and evidence requirements

Outcome 1

Demonstrate knowledge of the operation and operating principles of a dehumidifier or heat pump.

Evidence requirements

1.1 Operating components of the dehumidifier or heat pump are identified, and their purposes are explained.

Range condenser, heating coils, water disposal system.

1.2 Operating parameters and processing capability of dehumidifiers or heat pumps used at the workplace are defined.

1.3 Construction materials used for dehumidifier or heat pump drying sheds in use in New Zealand are described.

Range materials – aluminium and/or polystyrene, insulated plywood, galvanised steel and/or polystyrene.

1.4 Roles and responsibilities of the dehumidifier or heat pump operator are described in accordance with worksite documentation.

Outcome 2

Manage hazards associated with drying wood products using a dehumidifiers is or heat pump process. id rd r Evidence requirements ada ndn 2.1 Hazards associated with drying wooda productsta using a dehumidifier or heat pump process are identified ands actionst s to beg takeng to isolate, minimise or eliminate the hazards are describedt it in accordancen in with worksite documentation. i n ri ir un u pi p Range hazards smay includex butx are not limited to – dust, noise, moving equipment.is i e e hTh 2.2 Safe workT practices associated with drying wood products using a dehumidifier or heat pump process are used in accordance with worksite documentation and legislative requirements.

Competenz Ó New Zealand Qualifications Authority 2018 SSB Code 101571 NZQA Expiring unit standard 145 version 6 Page 3 of 5

Range practices may include but are not limited to – isolation procedures, lock-outs, emergency stops, machine guarding, wearing appropriate safety equipment.

Outcome 3

Dry wood using a dehumidifier or heat pump.

Evidence requirements

3.1 Input timber is checked against worksite documentation.

3.2 Timber is selected for uniformity of size and species, and loaded to optimise the air flows.

3.3 Dehumidifier or heat pump is operated to meet manufacturer's specifications and in accordance with worksite documentation.

3.4 Drying schedules are applied in accordance with worksite documentation with regard to species, timber thickness, and customer requirements.

3.5 Energy use is optimised in accordance with worksite documentation.

3.6 Wood charge turn-around time meets the requirements of worksite documentation.

3.7 Controller information is entered in accordance with worksite documentation.

3.8 Residue and waste are managed as required by legislative requirements and worksite documentation.

Outcome 4 Monitor the performance of a dehumidifier or heat pump and monitor wood charge. s is Evidence requirements i d rd 4.1 Housekeeping procedures are carried out ina accordancer a with legislative requirements and worksite documentation.d d nan 4.2 Output data are monitored and usedta sto tdetermine gthe end point of drying. st ngin 4.3 Operating faults that affecti ttimberni dryingri areir recognised and corrective action is taken in accordance withn worksiteu documentation.i p us xpx 4.4 Equipment faultsis handi malfunctionse e are identified and corrective action taken in accordanceTh withT manufacturer’s requirements and worksite documentation. 4.5 Drying schedule is amended in response to changing dehumidifier or heat pump conditions.

Competenz Ó New Zealand Qualifications Authority 2018 SSB Code 101571 NZQA Expiring unit standard 145 version 6 Page 4 of 5

4.6 Characteristics of dry product are checked against specification requirements.

Range moisture content, drying defects.

4.7 All required documentation is completed in accordance with worksite documentation.

Outcome 5

Complete maintenance requirements specific to a dehumidifier or heat pump.

Evidence requirements

5.1 Preventative maintenance and cleaning schedule for a dehumidifier or heat pump is carried out in accordance with worksite documentation.

This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below.

Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 5 July 1993 31 December 2015 Review 2 24 October 1996 31 December 2015 Review 3 10 February 1999 31 December 2015 Review 4 18 December 2006 31 December 2015 Review 5 18 April 2013 31 December 2015 Rollover 6 16 April 2015 31 December 2018

Consent and Moderation Requirements (CMR) reference 0173 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do . s is Please note id Providers must be granted consent to assess against standardsrd r (accredited) by NZQA, before they can report credits from assessment againsta unit standardsa or deliver courses of study leading to that assessment. dnd ana Industry Training Organisations must be grantedt s consentt to assessg against standards by NZQA before they can register credits from s assessmentt ng iagainstn unit standards. itni ri ir Providers and Industry Training Organisations,nu i whichp have been granted consent and which are assessing against unitu standards pmustx engage with the moderation system that applies to those standards.s is xe hi h e Requirements for consentT T to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing

Competenz Ó New Zealand Qualifications Authority 2018 SSB Code 101571 NZQA Expiring unit standard 145 version 6 Page 5 of 5 to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements.

is is d d r ar dad nan ta t s s gng it it inri nun irpi us xpx ishi e e ThT

Competenz Ó New Zealand Qualifications Authority 2018 SSB Code 101571