1. CITRIC ACID

1. PRODUCT CHARACTERISTICS

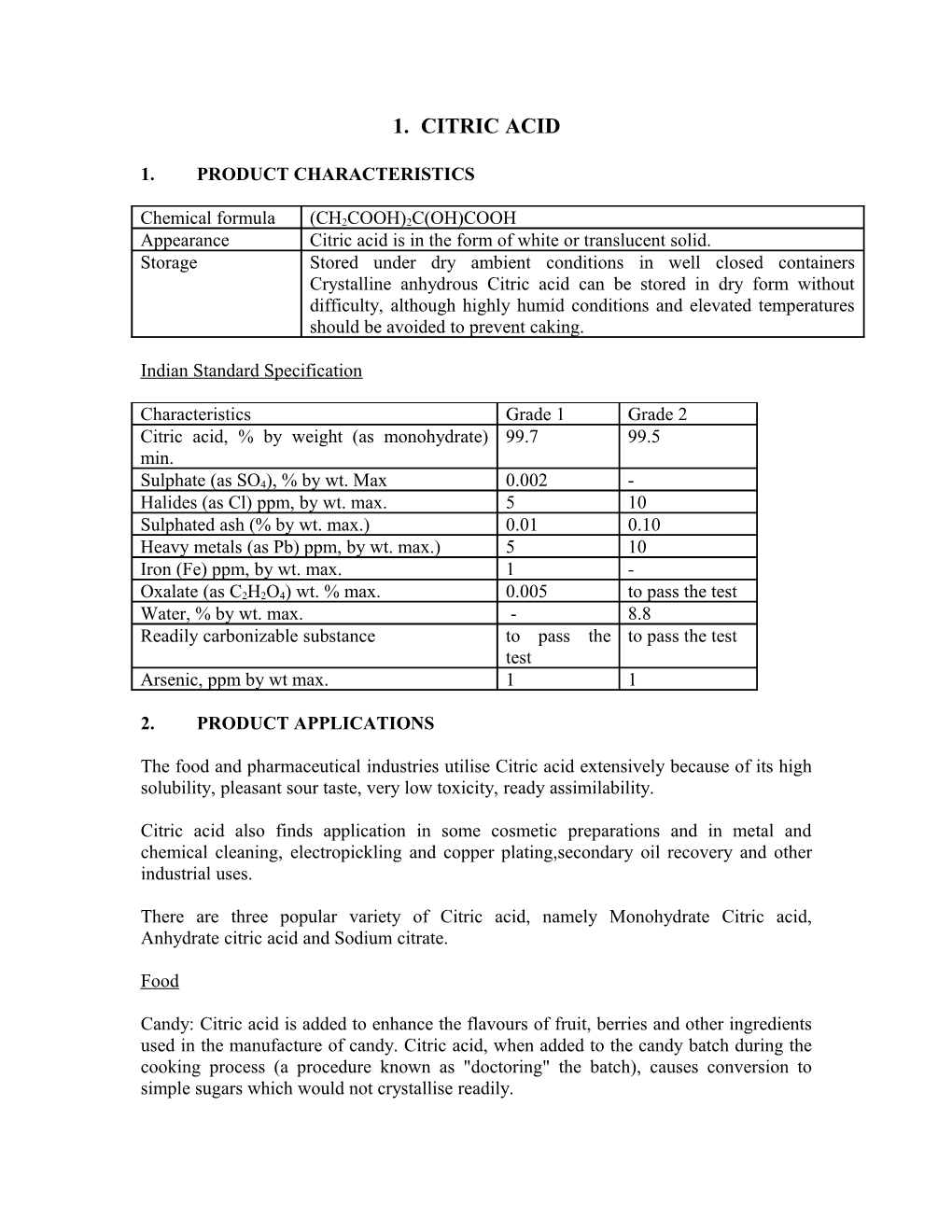

Chemical formula (CH2COOH)2C(OH)COOH Appearance Citric acid is in the form of white or translucent solid. Storage Stored under dry ambient conditions in well closed containers Crystalline anhydrous Citric acid can be stored in dry form without difficulty, although highly humid conditions and elevated temperatures should be avoided to prevent caking.

Indian Standard Specification

Characteristics Grade 1 Grade 2 Citric acid, % by weight (as monohydrate) 99.7 99.5 min.

Sulphate (as SO4), % by wt. Max 0.002 - Halides (as Cl) ppm, by wt. max. 5 10 Sulphated ash (% by wt. max.) 0.01 0.10 Heavy metals (as Pb) ppm, by wt. max.) 5 10 Iron (Fe) ppm, by wt. max. 1 -

Oxalate (as C2H2O4) wt. % max. 0.005 to pass the test Water, % by wt. max. - 8.8 Readily carbonizable substance to pass the to pass the test test Arsenic, ppm by wt max. 1 1

2. PRODUCT APPLICATIONS

The food and pharmaceutical industries utilise Citric acid extensively because of its high solubility, pleasant sour taste, very low toxicity, ready assimilability.

Citric acid also finds application in some cosmetic preparations and in metal and chemical cleaning, electropickling and copper plating,secondary oil recovery and other industrial uses.

There are three popular variety of Citric acid, namely Monohydrate Citric acid, Anhydrate citric acid and Sodium citrate.

Food

Candy: Citric acid is added to enhance the flavours of fruit, berries and other ingredients used in the manufacture of candy. Citric acid, when added to the candy batch during the cooking process (a procedure known as "doctoring" the batch), causes conversion to simple sugars which would not crystallise readily. Desserts: In the manufacture of Gelatin desserts, careful control of pH is important, as the setting qualities of the gelatin are a function of pH. Citric acid not only permits pH adjustment to the optimum (3.0 to 3.5) but adds flavour and refreshing properties that account for its popularity and wide use. The solubility and non toxic qualities of Citric acid are also important in this application.

Jellies, Jams and preserves: Citric acid serves to adjust the pH of jellies, jams or preserve mixtures to the optimum range, where pectin can act most effectively. Certain foods would not naturally contain sufficient acids to give the proper pH. The use of Citric acid also gives the desired degree of flavour, which are important to jellies. After the jelly juice-pectic sugar mixture is cooked and concentrated, Citric acid is added. Many processors use juice concentrates as a starting point and add Citric acid and other ingredients directly to the concentrates.

Soft drinks and syrups: Since Citric acid occurs naturally in fruits, it is the preferred acidulant for carbonated and still beverages. Citric acid adds refreshing properties to the drink, often duplicating natural fruit products. It acts as a preservative in syrups and the finished beverage and aids in obtaining the desired bouquet by modifying the sweet flavours. It sequesters harmful metals which cause haze and accelerates deterioration of colour and flavour.

The amount of Citric acid added to soft drinks depends upon the flavour and the particular end uses intended. Some syrup flavours, such as grape or orange, contain as little as 0.5 OZ of Citric acid per gallon of syrup, whereas the Citric content of certain mixers may be as high as 4 OZ per gallon. Sufficient Citric acid should be added to give a final pH of 2.5 to 4.5.

Anhydrous Citric acid is generally used as a 50% solution prepared by dissolving 2 kilograms of anhydrous Citric acid in enough water to make 5 litres of final solution.

Soft drink tablets: Tablets containing Citric acid, an alkaline salt, a sweetening agent and various flavours have been placed on the market, which effervesce when dissolved in water. Carbonation of the water solution is caused by the release of carbon dioxide when Citric acid reacts with a metal bicarbonate.

Fruit and vegetable juices: In general, lower pH value exert a protective effect on fruit juice pigment. Strawberry fountain syrup in particular is colour stabilized by Citric acid. The natural flavours of grape and other fruit juices are greatly enhanced by the tartness which Citric acid gives. The lower pH increase the resistance to spoilage.

Frozen fruits: Citric acid is used for two purposes in the processing of fruits for frozen packs. First, since lye peeling operations are common, it is important after a thorough water washing to neutralise the residual lye by dipping fruits or vegetables in 1 to 2% Citric acid solutions. Since residual alkali destroys natural ascorbic acid, it is extremely important that the last traces be neutralised. The Citric acid further stabilises Ascorbic acid by lowering the pH to inactivate the oxidative enzymes present. In addition, the Citric acid retards destruction of Ascorbic acid by binding harmful metal contaminants.

Citric acid in addition to D-erythorbic acid (D-araboascorbic acid) or sodium-D- erythorbate, when added to products such as peaches, apricots, plums, pears and cherries protects the fruit from undesirable colour and flavour changes due to oxidation. Citric acid complexes contain metals which accelerate oxidation. The net result is that discolouration is retarded and flavours and natural vitamins are protected.

Pharmaceuticals:

The citrate ion is rapidly and almost completely oxidised, less than 1% being excreted unchanged in the urine. Intravenous injection shortens the coagulation time of the blood, but in vitro the citrate ion acts as an anticoagulant.

The free acid is employed in pharmaceuticals preparations as an acidulant and to enhance the flavour of syrups, solutions and elixirs.

With Sodium bicarbonate, Citric acid is used in many effervescent powders and tablets to liberate carbon dioxide on the addition of water in the large scale manufacture of these tablets and powders.

Citric acid salt such as sodium citrate and potassium citrates are also used in the mixture. The free acid may also be employed as an acidulant in mild astringent preparations. Many of the salts are important pharmaceuticals.

Illustrative list of Formulations using citrates

S.No. Type of Formulations Citrates used 1. Antianaemic iron tonic Ferric ammonium citrate 2. Antianaemic liver vitamin tonic Choline dihydrogen citrate 3. Vitamin amino acid tonic Choline dihydrogen citrate 4. Liver tonic Choline dihydrogen citrate 5. Antipyretic analgesic mixture Potassium citrate 6. Cough syrup Sodium citrate 7. Cold, cough and fever remedy Citric acid 8. Anti dysentry anti syrup diarrhoeal Caffeine citrate Piperazin citrate Diethyl carbamazin citrate Ferrous calcium citrate

9. Antiestogens ie, a fertility Clomiphene dihydrogen citrate inducer

Cosmetics:-

Hair Rinses and setting fluids: Citric acid rinses have enjoyed wide popularity for many years. Hair rinsed with a small quantity of the Citric acid in water becomes lustrous. In addition, Citric acid added to a solution of dextrin and glycerol with ammonium chloride, hydrogen sulphide and potassium hydroxide to pH 10, makes a hair setting fluid that has excellent holding opportunities.

Lotions: Citric acid has been suggested for use in astringent lotions, to treat oily skin having large pores and in bleaching lotions where a mild acid is preferred to adjust pH and to acts as a sequestrant.

Other industrial applications:

Many of the industrial applications of Citric acid are based not only upon its acidic properties, but also upon its powerful sequestering action with various transient metals, such as iron, copper, nickel, cobalt, chromium and manganese.

Metal cleaning: Before the layers of rust, scale and tarnish can be removed efficiently from metals, the grease, dirt and oil must be eliminated by precleaning. Most oil and grease removal is accomplished with organic solvents, emulsions, or alkali systems. The Citric acid dip follows to remove tarnish and rust and produces a shiny surface.

Certain aluminium brightener formulations also contain Citric acid, as do general metal cleaners and polishes for home use. Citric acid is the product of choice for home use because it is non toxic and completely safe. Citric acid, in combination as a paste or powder to copper surfaces, produces a brilliant shine.

Rust and scale removal: Citric acid and Ammonium citrate has been used for rust and scale removal for many years.

Ammonical Citric acid solutions in addition to their efficient cleaning action, offer the desired advantage of being nontoxic. Personnel are not exposed to the hazards, customarily experienced with other compounds.

Chemical cleaning: Modern high pressure steam generators contain various sections fabricated from austenitic materials which required monochloride containing Citric acids for cleaning. Citric acid also serves to clean atomic reactors and chemical process equipment.

The ammoniated Citric acid is also used for the removal of boiler oxides.

Electro pickling: Citric acid at levels of 0.1% is extremely effective in the electropickling of copper and its alloys. This process is generally accomplished in the presence of aqueous solutions of ferric salts. Citric acid in combination with these salts removes scale, produces a bright, smooth, natural surface and prevents discolouration. Citric acid enjoys use in alkaline anodic pickling and when combined with sulphuric acid in pickling processes, contributes greatly to the stability of the pickling solution. Copper plating: The addition of Citric acid to copper cyanide plating solutions increases both cathode and anode efficiency and yields smooth, lustrous, light and streak free surfaces. The desirable effect on citrate ion in copper plating baths include a bright surface, a smooth copper deposit in a short period, reduced effect of impurities and greater efficiency in plating on stainless steel magnesium, zinc, lead and aluminium.

Secondary oil recovery: Citric acid a powerful sequestering agent, keeps iron in solution and prevents injection rates from decreasing as a result of iron plugged conditions, When a previously plugged well is cleaned, Citric acid prevents replugging.

Tanning: Citric acid as a component of the tanning liquors does not cause undesirable smelling of the hide. The use of Citric acid to adjust the pH of tanning liquors has been recommended as it is the acid, whose properties must closely approach those of the mixture of acids naturally present in tanning materials.

Bottle washing compounds: In hard water areas, the use of caustic bottle washing compounds results in insoluble residues on bottles and equipment. Citric acid is used to prevent the formation of hard water scale.

Printing: Citric acid acts as a stabiliser in diazo-sensitised materials used to make diazo paper. The most important function of this stabiliser is to prevent the "precoupling" of diazo and coupler while the product is still on the shelf.

Miscellaneous: Citric acid is the starting point in the manufacture of various esters and of the citrates of sodium, ammonium, bismuth, calcium. ferric iron, lithium, magnesium, manganese, potassium and strontium.

Citric acid is also used in floor cements, linoleum, inks, silvering compounds and algicide formulations as well as in the dyeing of fabrics, in the stablization of peroxides and in the processes for removal of contamination of radioactive isotopes.

New applications

Pesticide formulations: The Scientists tentatively suggest that the inclusion in pesticide formulations of a chemical like Citric acid would help lower insecticide resistance in insects.

Food preservation: Citric acid and Potassium sorbate as additives in ice to preserve fish.

The Food and Drug Administration of USA has approved recently the use of ice containing 0.2% Citric acid and 0.05% potassium sorbate for the preservation of whole fish. Two additives should be both of food grade. Insecticides:-The scientists at the Central Food Technological Research Institute, Mysore studied the effect of feeding Citric acid to houseflies and their resistance to insecticides. The insecticides studied were, Permethrin, Malathion, Bromophos and Lindane.

Citric acid controls morphine loss from poppy:-

Scientists trying to prevent loss of Morphine from the fresh latex of poppy plants have found that Citric acid helps them in the task. The Morphine content of poppy latex declines on contact with air and sunlight and researchers are trying to identify chemicals that when sprayed on plants can prevent this loss. They attribute the loss to activation of the enzyme peroxidase.

Studies by scientists at the Acharya Narendra Dev University of Agriculture and Technology, at Faizabad in Uttar Pradesh, show that Citric acid is the most effective agent. Others that stem morphine loss are potassium sulphate, zinc sulphate and calcium carbonate, Ethelating agents such as Citric acid, tartaric acid and ascorbic acid inhibit deterioration of the latex when sprayed along with sodium chloride.

3. IMPORTS Around 7000 tonnes per annum

4. EXPORT DETAILS Small quantity

Anti dumping duty

The Government notified that the anti dumping duty on Citric Acid should not exceed the difference between the export price and landed value of Rs.58,925 per tonne.The preliminary duty was recommended on October 20, 1998 and notified on November 24, 1998 This had effect up to and inclusive of May 23,1999.

5. INDIAN MANUFACTURERS

* Citric India Ltd., Maharashtra * Citurgia Bio Chemicals Ltd., Mumbai * Bharat Starch Industries Ltd.,Baroda (reported to be not in operation)

6. DEMAND SUPPLY TRENDS

Indian demand level Around 12,000 tonnes per annum

Growth rate in demand 8 to 9% per annum

7. MANUFACTURING PROCESS

The most important commercial source of Citric acid is the mycological fermentation of carbohydrates (such as cane molasses). Citrus fruit and pine apples are also used. Citric acid is manufactured by the following processes.

1. By fermentation of molasses either by surface fermentation or submerged fermentation

2. Recovery from lemon juice and pine apple waste

Deep fermentation is the main commercial route to manufacture Citric acid.

The fermentation medium which consists of dextrose or sucrose is aerated continuously by bubbling air through it.

Citric acid can also be produced from corn sugar using submerged culture fermentation.

Other process include liquid surface fermentation where a mixture based on beet or cane molasses is fermented in shallow Aluminium pans.

Solid state fermentation uses moist estimated to be 80 of worldwide capacity.

Technology development

Improving the efficiency of the conventional Citric acid fermentation process:-

Strathelyde and Glasgow Universities in Scotland carried out joint research for the manufacture of Citric acid. The conventional Citric acid process is based on fermentation of sucrose solution by the fungus Aspergillus Niger.

Commercial process is carried out in giant fermentation vats using batch production.

Sucrose solution is pumped into the vat, where fungus spores are added and allowed to grow and then Citric acid is collected and the vat is refilled with nutrient to repeat the process.

Recovery of Citric acid:-

Anion exchange resin like DOWEX 66 can be used to recover Citric acid from fermentation broth by operating at a pH below the first ionization constant, followed by elution with an alkaline solution.

Basee and Sirkas have used a hollow fiber non dispersive extraction, made of hydrophobic polypropylene (250 microns id and 290 microns od) for extracting Citric acid with trioctylamine, dissolved in MIBK; Back extraction is done with NaOH.

The Cahn method: An unusual method of Citric acid production was advocated by F.J. Cahn in 1934 and reported by W.L.Owen and also by Prescott and Dunn.

The Cahn process utilised blackstrap molasses as the source of fermentable sugar and sugarcane bagasse as an inert material for the suspension of the mould mycelia. The fermentation was carried out in shallow trays with false bottoms of iron screens and the impregnated bagasse which contained 15.3 parts bagasse, 63.7 parts added water and 21.0 parts molasses, was spread as a layer 40 mm thick resting on the screen. No forced aeration was necessary, as sufficient draught was created by the heat of oxidation. The fermentation was completed in less than 4 days and the yield of acid on molasses was about 19% (i.e. about 38% of fermentable sugars).

This process has not been used commercially but with certain modifications it could probably have been utilised where small scale production is envisaged in cane sugar countries, provided the steam and water consumption are brought down to more reasonable figures.

8. GLOBAL SCENARIO

Global demand 7,04,000 tonnes per annum

Global Citric acid consumption is estimated to be 80% of worldwide capacity.

In developed countries, 65% of Citric acid consumption is in food and beverages and 20% in household detergents.

Estimated global growth rate in demand: 4 to 5% per annum

Global major players

Plant capacity (100% anhydrous)

Company Location Capacity in `000 tonnes per annum Jungbunzlauer Perhofen,Austria 136 Archer Daniels Southport 98 Midland NC,US Ringaskiddy, 45 Co Cork, Ireland Hoffmann-La Roche Tienen, Belgium 90 Cargill Eddyville, Iowa,US 72.6 Tate & Lyle Dayton, Ohio, US 60

Global market pattern

Europe 35% US 33% China 20% Others 12%

Global consumption pattern

Food and beverages 60% Pharmaceuticals 12% Detergents 12% Metal cleaning solutions 6% Textile dyes 5% Cosmetics 3% Others 2%

9. RECOMMENDATIONS

Considering the fact that Citric acid can be produced from cane molasses by fermentation process, the project has excellent relevance to Tamil Nadu in view of the large availability of Molasses in the state.

Recommended capacity 15000 tonnes per annum

Estimated project cost Rs.50 crores