ECE 477 Digital Systems Senior Design Project Rev 4/11

Homework 12: Environmental Impact Lifecycle Analysis and Ethical Challenges

Team Code Name: FEST Group No: 5 Team Member Completing This Homework: Christopher Sakalis E-mail Address of Team Member: [email protected]

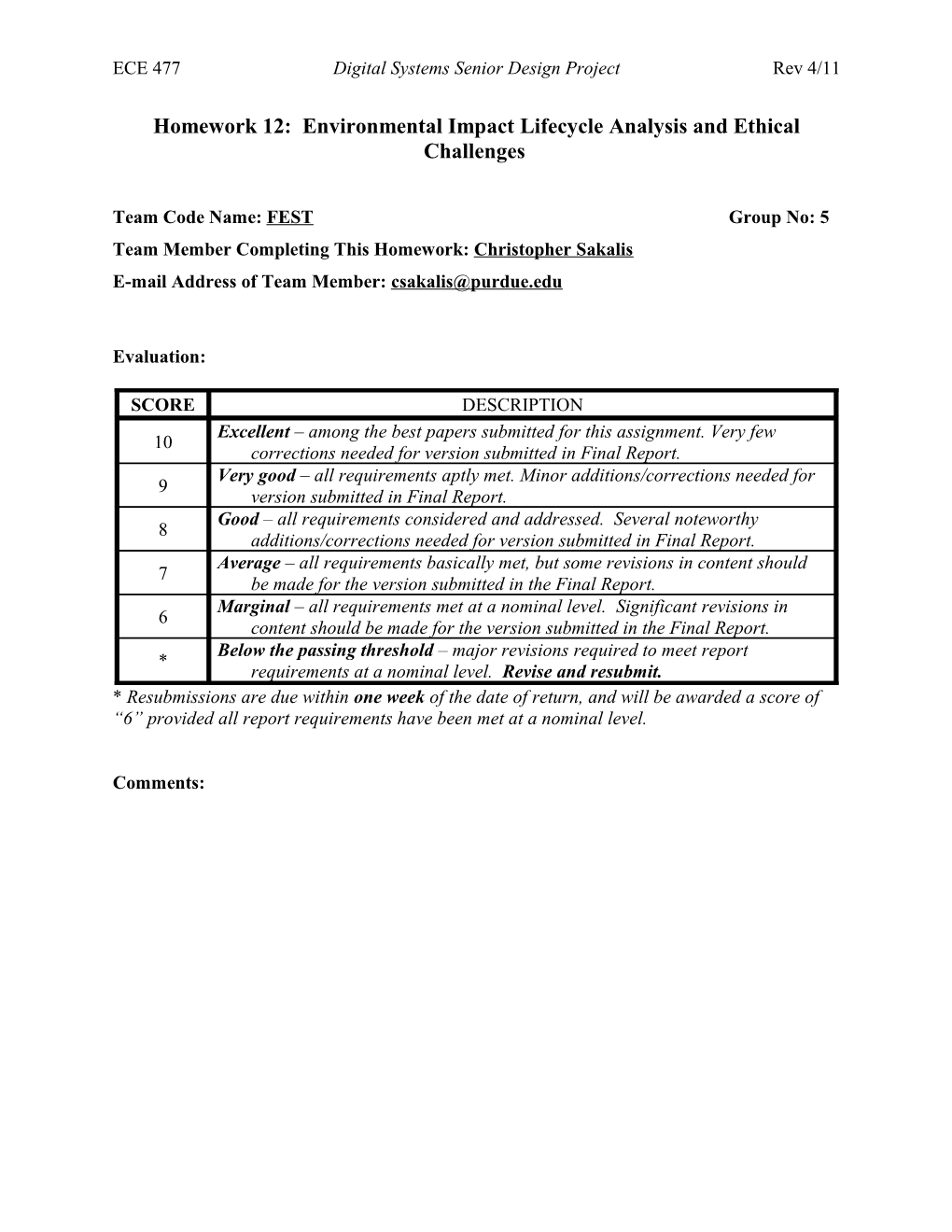

Evaluation:

SCORE DESCRIPTION Excellent – among the best papers submitted for this assignment. Very few 10 corrections needed for version submitted in Final Report. Very good – all requirements aptly met. Minor additions/corrections needed for 9 version submitted in Final Report. Good – all requirements considered and addressed. Several noteworthy 8 additions/corrections needed for version submitted in Final Report. Average – all requirements basically met, but some revisions in content should 7 be made for the version submitted in the Final Report. Marginal – all requirements met at a nominal level. Significant revisions in 6 content should be made for the version submitted in the Final Report. Below the passing threshold – major revisions required to meet report * requirements at a nominal level. Revise and resubmit. * Resubmissions are due within one week of the date of return, and will be awarded a score of “6” provided all report requirements have been met at a nominal level.

Comments: ECE 477 Digital Systems Senior Design Project Rev 8/09

1.0 Introduction

The FEST design is a speakerphone testing system. With the assistance of some peripherals such as the Sound Level Meter (RS-232 port), a Microphone Preamplifier and Speaker Amplifier, the product is able to generate signals, record the signals generated from the DUT, and finally check the quality of the speakerphone of the DUT. Various commercially available peripherals are compatible with the FEST design which, depending on their manufacturer, have different levels of environmental friendliness and ethical challenges which will not be analyzed. The main environmental issue with the FEST design is the use of various chemicals in its manufacturing stage and the safe disposal of them after it the device is retired. The ethical issues are mainly focused on the safety of the user and possible use of the device for purposes other than the ones intended and possibly unlawful as according to the IEEE Code of Ethics [1].

2.0 Environmental Impact Analysis The FEST design includes many components that may cause environmental harm if the device and its parts are not properly handled during its life cycle. The use of chemicals is mostly present in the manufacturing stage, while the handling of the parts after the device is retired is in the disposal/recycling stage of the device without leaving out the possibility that either procedures may be present in other stages of the products life cycle. In general, the FEST design contains several common parts in its ICs and PCBs found in everyday electrical equipment which, if left unattended after their demise or retirement, could potentially harm the environment. As mentioned earlier, most of chemical usage occurs in the manufacturing stage, with first being the production of the PCB; or any PCB for that matter. The conductivity paths on the PCB is made out of copper which is the main waste generated in the manufacturing procedure of after placing a thin layer of copper (the aforementioned paths) on the PCB and the drilling of through- holes and vias, where required. The PCB is then scrubbed to remove the copper particles left by the drill resulting in a significant source of copper waste which if not removed by special equipment and instead left to mix with other waste streams, the copper can dissolve [6] thus posing both an environmental hazard and a possible loss of, albeit small, revenue.

-2- ECE 477 Digital Systems Senior Design Project Rev 8/09

The Integrated Circuits (ICs) found on the PCB also contain a number of hazardous materials on the semiconductor level: Poisonous dopants such as arsenic, antimony and phosphorus, compounds such as arsine, phosphine and silane, and finally highly reactive liquids, such ashydrogen peroxide, fuming nitric acid, sulfuric acid and hydrofluoric acid [7]. We should ensure that throughout the manufacture of the product, the risk to exposure to these chemicals is reduced as much possible and also comply with the “Occupational Safety and Health Standards” set by the United States Department of Labor [5]. Finally, to ensure conductivity in the surface pads or in the through-holes, solder is used. There is a a number of common solders used today [3]: Lead/tin solders found in most solder alloys in the past is a combination of tin and lead. “Lead overexposure is one of the most common overexposures found in industry and is a leading cause of workplace illness” according to the Occupational Safety & Health Administration (O.S.H.A.) from the United States Department of Labor [4]. “Lead-free” solders are available but they are not used as much as others in the electronics industry due to the high temperature required to achieve the “lead-free” melting point. Other metals used for solder alloys are silver, cadmium, antimony, zinc, indium, while traces of arsenic, chromium, bismuth, cobalt, nickel, selenium, thallium, and vanadium are also found in base and filler metals [3]. Most of these metals are hazardous to some degrees, although the “greatest danger to health lies in the presence of lead or cadmium in the solder alloy” according to O.S.H.A. [3]. Also, the gas produced from soldering when using flux materials containing rosin is also harmful to the solderers health if background ventilation is poor [2]. To avoid such hazardous exposures we need to ensure that the production of our product complies with the “Occupational Safety and Health Standards” set by the United States Department of Labor [5] and in general provide a healthy working environment with proper handling of chemicals used in the manufacturing procedure. We can however reduce hazardous materials being generated, even after complying to these standards. First of all, we could reduce the number of PCB’s to 1, since our current design uses two due to the restriction of the free EAGLE Version to the size of 3.15in to 3.95in. By doing so the most obvious result is reduction of the chemicals and materials used to make the second PCB. Other benefits are the reduction of voltage regulators from four to two thus reducing

-3- ECE 477 Digital Systems Senior Design Project Rev 8/09 the (unlikely) possibility of the design overheating, removing the cost of extra parts and ultimately less waste generated by both manufacturing and recycling stages. During the normal use stage of the FEST design, the device does not consume more than 100 mA when its in ON state i.e. calculations are being performed, code is ran on the microcontroller, data is being recorded or generated etc. The stand-by mode of the device consumes even less: no more 1mA. This is a state which the device might be have erroneous code and fails to perform as expected or awaits for user input, such as start recording, select data to delete/ etc. In other words, whenever the devices is idle, simply being plugged in its 9V “wall- wart” adaptor of 6W Power. When the device is turned OFF, or simply power is cut off either by removing the adaptor or by a power outage, there is no power consumption. A way to reduce power consumption is, as mentioned earlier, combining the two PCB’s into one, thus reducing the number of voltage regulators from four to two since the design uses a total of four power regulators that in reality are used to generate two sources of 5V and 3.3V to power different types of parts and by reducing their number, the total power consumption should decrease. Since our device features mostly electrical components, the design should strive for recycling as many parts as possible and that can be done by referencing recycling methods and procedures that the user can follow if he wishes to retire the product. There are a number of recyclable metals in our design and in some other designs even precious metals that can be extracted from PCB’s and its soldered components during its recycling stage. Various companies exist with the sole purpose of buying old PCB’s and harvesting their base components which contain “heavy metals and precious metals such as gold, palladium, silver, copper and other hazardous materials” which are not supposed to be discarded in landfills [8]. Placing stickers on the device that contains recycling information about recycling companies specializing in electronic waste is also another way that might help reduce the amount of hazardous waste send to landfills. Other locations that could be used to contain similar and perhaps more detailed information would be the user manual or a case used to place and carry the device. Another part of the design that will require special handling after its retirement is the LCD screen which lamps contain mercury a hazardous material.

-4- ECE 477 Digital Systems Senior Design Project Rev 8/09

3.0 Ethical Challenges

As mentioned in the introduction, an ethical issue surrounding the FEST design is the safety of the user. Another ethical challenge is to ensure that the analysis of the quality test of the DUT is truthful i.e. when a signal generated by a speakerphone and recorded by the FEST product, the statement that the quality is indeed “good” is truthful. There is also the possibility of some parts failing either unexpectedly, peripherals failing due to incompatibility issues and simply due to prolonged usage or idleness. Finally there is another ethical challenge that the FEST design poses: Since its user will most likely be someone testing speakerphones or some kind of audio equipment, most likely in a company producing such products, it may be used to record conversations unrelated to quality testing of speakerphones. Regarding the safety of the user, there is the possibility, although highly unlikely, of combustion of part of the device, specifically the voltage regulators. It could potentially hold. Such an event could be aided by the device being operating in relatively high temperatures for a prolong amount of time. The device was design with a “room temperature” environment in mind and no extreme circumstances since for those cases, different design decisions would have been made to deal with the new circumstances. A warning label informing the user of the potential danger of exposure to higher temperatures could be used as well as warning for the possibility of the device overheating if used exhaustively or if the device is requested to perform in such extreme environments, a special order could be available for the user to receive an upgraded product designed for such environments. As for the claims of deeming a DUT as having “good quality” in transmitting and receiving signals can be seen as true if the product receives certification supporting these claims. An example of this certification would be similar to THX certification [9]. The last ethical consideration is whether or not the device could be used for recording conversations between the user and another third party i.e. spy on others. The device itself could be used to record virtually any conversation close enough to record, however if a conversation takes place while recording, the testing procedure is ruined since the signal intended to be generated/recorded has now been contaminated by the conversation meaning that the testing procedure must start over. However there is the possibility of a conversation being unknowingly recorded. In such a case the only thing we can advice is close monitoring of the product and, if adhering with company policy, allow only certain employees access to the device and its usage

-5- ECE 477 Digital Systems Senior Design Project Rev 8/09 or allow operation of the device in a more controlled environment with the DUT and the testing taking place in a soundproof environment, thus eliminating any possible recording outside of the testing environment.

4.0 Summary

The FEST design uses two PCB’s populated with IC’s with the purpose of determining the quality of a speakerphone with the assistance of a number of peripherals. During the manufacturing stage there is a number of hazardous chemicals that require a certain degree of monitoring to ensure the safety of workers and users alike. During its normal use stage the product is powered by using a 6W “wall-wart” adaptor providing 9V, the design consume no more than 100mA when ON and less than 1mA when it is idle. When turned off or its power is cut off, the power consumption drops to zero. When the device is retired there should be information printed on both the device and the user manual regarding the procedures the user must follow for safe disposal of the device and its many parts. The design itself must hold up to the Code of Ethics set by the IEEE [1]. The ethical challenges posed by the usage of the FEST design are firstly the safety of the user in case the device overheats which can be accomplished either by placing a label on the product warning of such an occurrence especially if placed in high temperature conditions or if specifically required to performed in such conditions, create a version of the product designed for higher temperatures. The second ethical challenge is supporting the claim of “good quality” of the signals generated and received from the DUT which can be done by getting a certification similar in nature to the THX certification. The last ethical challenge is the possibility of unwanted recording of a conversation which can either be resolved by monitoring closely the usage of the product or using a soundproof environment to place the product and the DUT during testing thus eliminating all possibilities of recording possibly sensitive conversation between employees.

-6- ECE 477 Digital Systems Senior Design Project Rev 8/09

List of References

[1] IEEE.org. “IEEE Code of Ethics”. Internet: http://www.ieee.org/about/corporate/governance/p7-8.html [Accessed November 17, 2011].

[2] Health and Safety Executive HSE.gov.uk “Solder Fume and you” Internet: http://www.hse.gov.uk/pubns/indg248.pdf [Accessed November 17, 2011].

[3] United States Department of Labor – Occupational Safety & Health Administration: “ICP Backup Data Report for Soldering & Brazing Matrices (ARL 3560)”. Internet: http://www.osha.gov/dts/sltc/methods/inorganic/id206arl3560icp/id206arl3560icp.html [Accessed November 17, 2011].

[4] United States Department of Labor – Occupational Safety & Health Administration: “Lead”. Internet: http://www.osha.gov/SLTC/lead/index.html [Accessed November 17, 2011].

[5] United States Department of Labor – Occupational Safety & Health Administration: “Occupational Safety and Health Standards”. Internet: http://www.osha.gov/pls/oshaweb/owastand.display_standard_group? p_toc_level=1&p_part_number=1910 [Accessed November 18, 2011].

[6] International Network for Environmental Compliance and Enforcement – “INECE Chapter 7: Printed Circuit Board Manufacturing” INECE; 2011. Internet: http://www.inece.org/mmcourse/chapt7.pdf [Accessed November 18, 2011].

[7] “Semiconductor Fabrication: Hazardous materials”. Internet: http://en.wikipedia.org/wiki/Semiconductor_fabrication#Hazardous_materials [Accessed November 18, 2011].

[8] B.W. Recycling Inc. “Scrap PCB disposal & recycling services” http://www.webuyics.com/scrap-pcb.htm [Accessed November 18, 2011].

[9] THX.com – “THX Certification Performance Categories”. Internet: http://www.thx.com/consumer/home-entertainment/home-theater/thx-certification- performance-categories/ [Accessed November 18, 2011].

-7-