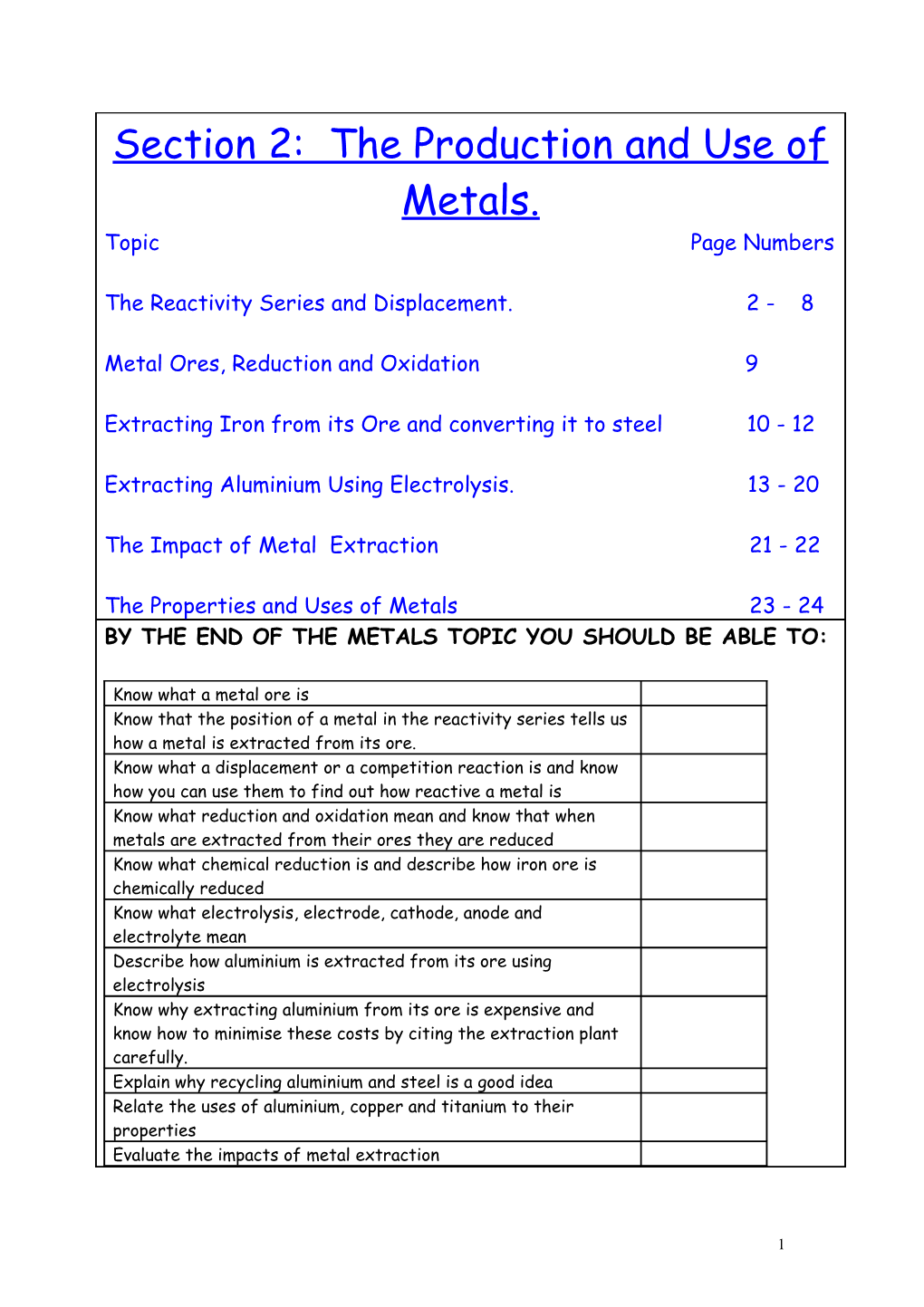

Section 2: The Production and Use of Metals. Topic Page Numbers

The Reactivity Series and Displacement. 2 - 8

Metal Ores, Reduction and Oxidation 9

Extracting Iron from its Ore and converting it to steel 10 - 12

Extracting Aluminium Using Electrolysis. 13 - 20

The Impact of Metal Extraction 21 - 22

The Properties and Uses of Metals 23 - 24 BY THE END OF THE METALS TOPIC YOU SHOULD BE ABLE TO:

Know what a metal ore is Know that the position of a metal in the reactivity series tells us how a metal is extracted from its ore. Know what a displacement or a competition reaction is and know how you can use them to find out how reactive a metal is Know what reduction and oxidation mean and know that when metals are extracted from their ores they are reduced Know what chemical reduction is and describe how iron ore is chemically reduced Know what electrolysis, electrode, cathode, anode and electrolyte mean Describe how aluminium is extracted from its ore using electrolysis Know why extracting aluminium from its ore is expensive and know how to minimise these costs by citing the extraction plant carefully. Explain why recycling aluminium and steel is a good idea Relate the uses of aluminium, copper and titanium to their properties Evaluate the impacts of metal extraction

1 The Reactivity Series and Displacement

The Reactivity Series Metals can be listed in order of reactivity; this is called a reactivity series. There are some non-metals here, you will see why later. Potassium K Sodium Na Calcium Ca Magnesium Mg Aluminium Al Carbon C Zinc Zn Iron Fe Tin Sn Lead Pb Hydrogen H Copper Cu Mercury Hg Silver Ag Gold Au Platinum Pt You don’t need to learn this but you will be expected to be able to use it in an exam.

Displacement of Metals from Metal Oxides

If you heat a metal oxide with a more reactive metal the metal will take the oxygen.

For example:

Copper Oxide + Magnesium Copper + Magnesium Oxide

The Copper is DISPLACED by the Magnesium. If a reaction has happened you will see a glow or flash. These reactions can also be called COMPETITION reactions as the 2 metals compete for the oxygen.

2 Metal oxide Displacement Experiment SAFETY: you must wear specs, use small amounts of chemicals and never put your face close to the mixture.

Instructions (Use the table below to work out which chemical you need to react)

1. Mix thoroughly 1 spatula full of metal powder with 1 spatula full of metal oxide powder on a tin lid.

2. Place this on the corner of a tripod (no gauze) on a heat proof mat

3. Heat strongly with a roaring Bunsen.

4. If there is no reaction after 30 seconds, remove the heat & allow to cool for a full 2 minutes – then tap the contents into a metal waste bin that has no paper in it.

5. Write “No reaction” in the appropriate box.

6. If there is a glow or flash of light, put a tick in the appropriate box below.

7. Then allow to cool & tap the contents into the bin.

Zinc powder Iron powder Magnesium Copper powder Lead powder powder (expensive) (toxic) Zinc No reac No reac No reac Oxide powder Iron III No reac No reac No reac oxide powder Magnesium No reac No reac No reac oxide powder Copper II No reac oxide √ powder Lead II No reac No reac oxide √ √ √ powder (t)

3 Conclusions

Write down the order of reactivity of the metals using your experimental results:

Displacement Reactions in Solution

Displacement reactions can also happen in solution. The more reactive metal displaces the less reactive metal from the compound that is in solution. The less reactive metal will come out of the solution.

For example:

Copper Sulphate + Magnesium Copper + Magnesium Sulphate

The Copper is DISPLACED by the Magnesium. If a reaction has happened you will see a colour change and a metal will come out of the solution.

Displacement Reactions in Solution Experiment SAFETY: you must wear goggles.

Instructions (Use the table on the next page to work out which chemical you need to react)

Mix each combination of chemicals in a dimple tray or test tubes. If you observe a colour change but a tick in the appropriate box.

4 Magnesium Copper Zinc Lead Iron (ribbon) (strip) (strip) (strip) (wool) Magnesium nitrate or No reac sulphate soln. Copper nitrate or No sulphate soln. reac Zinc sulphate or No nitrate soln. reac Lead nitrate No Soln. reac Iron (II) sulphate or No nitrate soln. reac

Conclusions

Write down the order of reactivity of the metals using your experimental results:

Questions

For each pair of chemicals that react, place a tick in the right hand box Iron + lead II nitrate solution Magnesium + zinc sulphate solution Copper II oxide + zinc Silver + gold nitrate Iron + zinc oxide

5 Try this typical GCSE question…

6 Complete the following…

7 Try this typical GCSE question…

8 Metal Ores, Reduction and Oxidation

Metal Ores

Metals are found in the earth’s crust. Most metals are found inside metal ores. Metals ores are metal compounds inside rocks. The most unreactive metals are found uncombined in the earth’s crust. Uncombined metals are said to be NATIVE. Examples of native metals are silver, gold and platinum.

Reduction and Oxidation

Metals must be extracted from their ores to be useful. To be extracted, oxygen must be removed from the metal. When oxygen is removed this is called REDUCTION. If something gains oxygen it is called OXIDATION.

For example:

Magnesium + Iron Oxide Iron + Magnesium Oxide

Magnesium is oxidised, Iron is reduced

9 Extracting Iron from its Ore and converting it to Steel

Relating the method for extracting a metal to its position in the reactivity series Potassium K Sodium Na These very reactive metals need a lot of energy to extract them Calcium Ca from their ore. Magnesium Mg They can be extracted using electrolysis Aluminium Al Carbon C Zinc Zn Iron Fe These moderately reactive metals need less energy to extract Tin Sn them from their ore. Lead Pb They can be extracted using chemical reduction Hydrogen H Copper Cu Mercury Hg Silver Ag Gold Au These unreactive metals are found native. They do not need to Platinum Pt be extracted

What is chemical reduction?

Chemical reduction is when a more reactive element takes the oxygen from the metal in the ore It is a type of displacement reaction. Carbon is normally used as it is cheap and readily available

How is Iron extracted?

Iron is extracted from its ore by chemical reduction using carbon:

Iron Oxide + Carbon Carbon Monoxide + Iron

Iron is REDUCED Carbon is OXIDISED

10 This happens inside something called a blast furnace: (you don’t need to know the details of this)

Converting Iron to Steel

A lot of the iron extracted is converted into steel Steel is more malleable, ductile and can be stronger than iron. Steel is a mixture of Iron and Carbon. When you mix a pure metal with other elements it is known as an ALLOY

11 Composition and uses of different types of steel

Different amounts of carbon and other metals can be added to iron to make the steel have different properties:

A summary of the properties of some different steels

type of iron alloyed with properties typical use steel

low carbon about 0.25 per easily shaped car body steel cent carbon panels

high up to 2.5 per hard cutting carbon cent carbon tools steel

stainless chromium and resistant to cutlery steel nickel corrosion and sinks

Recycling Steel

Steel is recycled by local councils in the UK

There are 3 reasons for recycling steel: 1. It uses 50% less energy than extracting more iron from iron ore 2. It conserves iron ore

3. It cuts down on emissions of greenhouse gases like CO2

12 Extracting Aluminium Using Electrolysis

What is electrolysis?

13 Metals that are very reactive can be extracted using electrolysis Electrolysis means “splitting using electricity” Ionic substances, like metal oxides break down into their elements during electrolysis. They must be molten to take part in electrolysis. Ionic solutions can also be broken down into their elements during electrolysis .

The following diagram shows the equipment needed for electrolysis:

The power supply is connected to 2 metal ELECTRODES The positive electrode is called the ANODE The negative electrode is called the CATHODE The ELECTROLYTE is the liquid that conducts electricity and completes the circuit.

How does electrolysis work?

14 When a compound is molten the positive and negative ions that make up the compound are free to move. The negative ions will move to the anode (the positive electrode) The positive ions will move to the cathode (the negative electrode)

For example in molten sodium chloride the Na+ ions will move to the cathode and the Cl- ions will move to the anode.

How is Electrolysis Used to Extract Aluminium

The main ore of aluminium is called BAUXITE it contains Al2O3 If bauxite is melted down electrolysis can be used to extract it The diagram below shows the electrolysis set up

15 3+ 2- The Al2O3 in the bauxite splits up into Al ions and O ions The Al3+ ions go to the cathode. There they gain 3 electrons to become molten aluminium. The equation for this is:

Al3+ + 3e- Al

The O2- ions go to the anode. There they lose 2 electrons to become oxygen gas which bubbles off. The equation for this is:

2- - 2O O2 + 4e

How Much Does Extracting Aluminium Cost?

. Extracting aluminium this way is expensive because: 1. It uses a large amount of electricity 2. The melting point of bauxite is very high so it will take a lot of energy to melt it.

We can reduce these costs by dissolving the bauxite in another ore of aluminium called cryolyte. This lowers the melting point so it takes less energy to melt

16 Siting the Aluminium Extraction Plant We can also reduce costs by carefully siting the extraction plant. These factors will help keep costs down:

1. Since the UK imports its bauxite (impure aluminium oxide) it makes sense that it should be sited near a deep water port on the coast. 2. Since huge amounts of electrical energy are needed, a good place to site would be at the bottom of a mountain range to take advantage of cheap hydroelectric power. 3. There ought to be a good road and rail network near-by to transport the finished product (aluminium) to all parts of the country. 4. Aluminium smelting is not that labour intensive, but siting the plant in areas of high unemployment will help provide much needed jobs.

Recycling aluminium also saves money as it uses only 5% of the energy required to extract it from bauxite and it saves waste

Questions Fill in the blanks… Alu ...... is a more expensive metal than i r . . due to the high cost of e ...... It is the e ...... current that keeps the aluminium o . . . . molten. Costs are kept as low as possible, however, by doing the following… a. adding c r ...... to the aluminium oxide to lower its melting point keeping the cell temperature only just above the melting point so energy is not unnecessarily wasted

17 a) Which metal is formed from bauxite?

b) What are the electrodes made of?

c) What is added to the bauxite to lower its melting point?

d) Write a half equation for what takes place at the cathode

e) Write a half equation for what takes place at the anode

f) What gas is produced at the anode?

g) Why does the anode have to be replaced periodically?

18 Fill in the blanks: The chief ore of aluminium is called ………………… . It is first purified to give a...... o………… or al……………, which has the formula …………… . Then this is red………… to give aluminium.

19 20 21 The Impact of Metal Extraction

Social Impacts Social Impacts are the effects metal extraction has on people’s lives and running a society.

Some examples of these are:

1. Metals that we extract are essential to us all. We need metals for buildings, cars, machines and lots of everyday items. 2. Metal extraction provides jobs for the local community. 3. Local recycling schemes are now much more widespread so people can easily recycle and less metal extraction is needed.

Economical Impacts Economical impacts are the effects metal extraction has on making money or keeping cost down.

Some examples of these are: 1. Quarried products are very valuable. Large quarrying companies in the UK have an annual turnover of hundreds of millions of pounds. 2. Aluminium extraction is incredibly expensive so recycling is used as a cheaper alternative 3. Metal ore extraction can provide a lot of jobs 4. Raw materials often have to be imported from abroad so can be expensive to buy.

22 Environmental Impacts Environmental impacts are the effects metal extraction has on pollution and wildlife.

Some examples of these are: 1. Metal ore quarries create scars in the landscape 2. Aluminium extraction requires huge amounts of electricity 3. Extracting some ores (e.g. lead, cadmium) can pollute waterways 4. Quarries can be built on land where endangered species live 5. Extracting Iron from its ore produces harmful waste materials

23 Properties and Uses of Metals The properties of metals decide what they are used for… Aluminium

The properties of aluminium are: 1. Good conductor of electricity and heat 2. Low density (it’s light) 3. Quite strong but not very hard 4. Doesn’t corrode easily so its doesn’t need painting 5. Flexible when thin

This means aluminium is used for: 1. Bike frames 2. Overhead power cables 3. Cooking Foil 4. Aeroplane Bodies

Copper

The properties of copper are: 1. Good conductor of electricity and heat 2. Fairly strong and moderately hard 3. Fairly high density (it’s heavy) 4. Doesn’t corrode easily so its doesn’t need painting 5. Very malleable and ductile

This means copper is used for: 1. Water pipes in a house 2. Electrical Wiring 3. In alloys in coins

24 Titanium The properties of titanium are: 1. Good conductor of electricity and heat 2. Very strong and very hard 3. Fairly low density (it’s quite light) 4. Doesn’t corrode

This means titanium is used for: 1. Replacement hip joints 2. Aircraft rivets 3. Golf Clubs

25 Relevant Internet and School Network Links In school, try these web links and click on the white arrow in the green square to view: http://www.yenka.com/freecontent/item.action?quick=tx http://www.yenka.com/freecontent/item.action?quick=tv http://www.yenka.com/freecontent/item.action?quick=tq http://www.yenka.com/freecontent/item.action?quick=tp# http://www.yenka.com/freecontent/item.action?quick=tw http://www.yenka.com/freecontent/item.action?quick=ty http://www.yenka.com/freecontent/item.action?quick=11g http://www.yenka.com/freecontent/item.action?quick=t7 http://www.yenka.com/freecontent/item.action?quick=sr# http://www.yenka.com/freecontent/item.action?quick=u5 http://www.yenka.com/freecontent/item.action?quick=u7 http://www.yenka.com/freecontent/item.action?quick=u6 http://www.yenka.com/freecontent/item.action?quick=u8 http://www.yenka.com/freecontent/item.action?quick=u9

School network Links: SUBJECTS > SCIENCE > CHEMISTRY > ABSORB CHEMISTRY FOR GCSE > REACTION OF METALS SUBJECTS > SCIENCE > CHEMISTRY > ABSORB CHEMISTRY FOR GCSE > DISPLACEMENT REACTIONS SUBJECTS > SCIENCE > CHEMISTRY > ABSORB CHEMISTRY FOR GCSE > METALS IN NATURE SUBJECTS > SCIENCE > CHEMISTRY > ABSORB CHEMISTRY FOR GCSE > REDUCTION OF METAL OXIDES BY CARBON SUBJECTS > SCIENCE > CHEMISTRY > ABSORB CHEMISTRY FOR GCSE > EXTRACTION OF IRON EXTRACTION OF ALUMINIUM SUBJECTS > SCIENCE > FOOTPRINTS > MATERIALS & THEIR PROPERTIES > EXTRACTION OF METALS (BE SELECTIVE)

26 SUBJECTS > SCIENCE > CHEMISTRY > ABSORB CHEMISTRY FOR GCSE > EXPLAINING ELECTROLYSIS SUBJECTS > SCIENCE > CHEMISTRY > ABSORB CHEMISTRY FOR GCSE > EXTRACTION OF LEAD BROMIDE SUBJECTS > SCIENCE > CHEMISTRY > ABSORB CHEMISTRY FOR GCSE > EXTRACTION OF REACTIVE METALS SUBJECTS > SCIENCE > MULTIMEDIA SCIENCE SCHOOL > CHEMISTRY > ELECTROCHEMISTRY, AND EXPLORE….

Useful websites

http://www.bbc.co.uk/history/games/blast/blast.shtml http://www.matter.org.uk/steelmatter/steelmaking/blast_furnac e.htm http://www.matter.org.uk/steelmatter/raw_materials/liquid_iron. htm www.btinternet.com/~chemistry.diagrams/electrolysisPbBr2.swf www.sciencelessons.co.uk/example.php http://www.bbc.co.uk/schools/gcsebitesize/science/aqa/rocks/me talsrev1.shtml

27