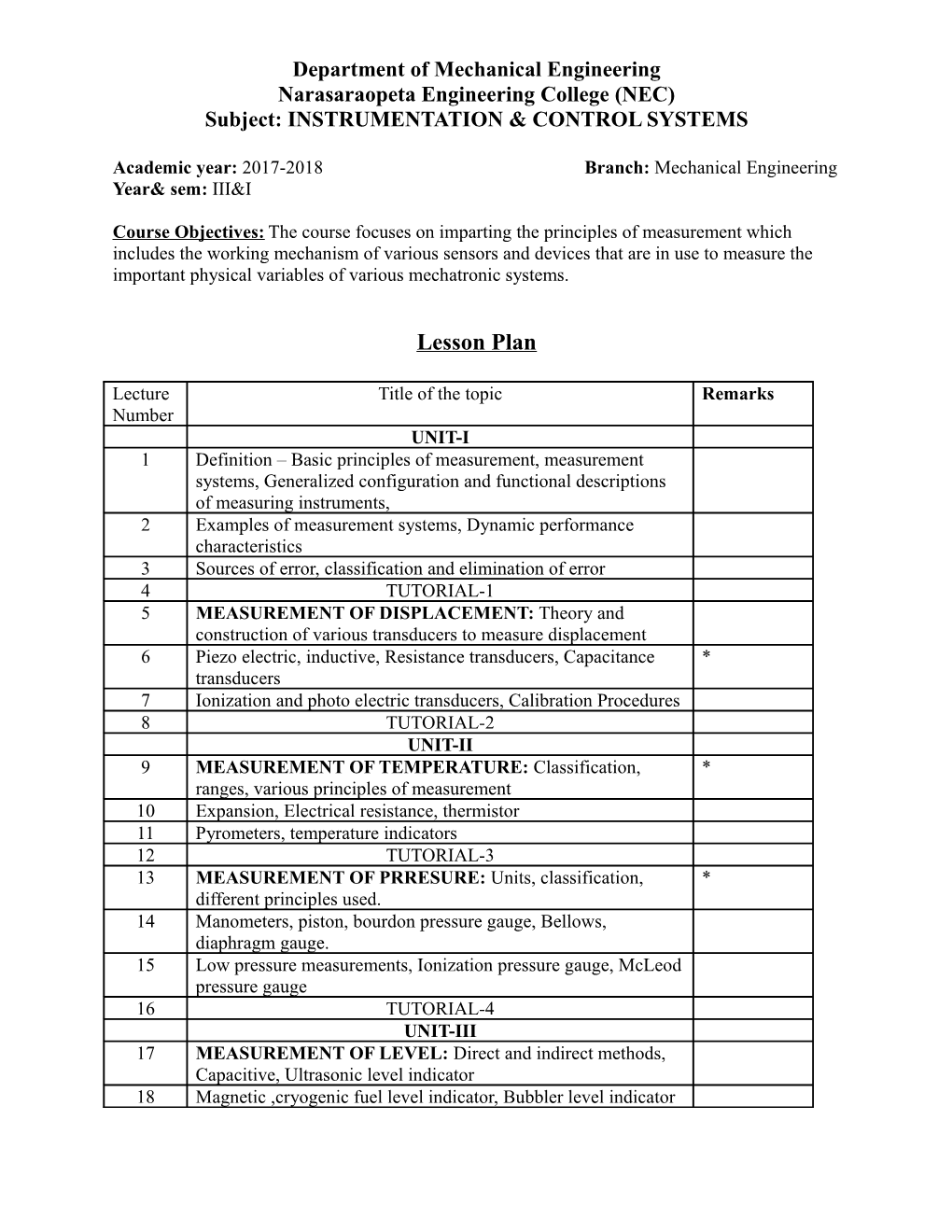

Department of Mechanical Engineering Narasaraopeta Engineering College (NEC) Subject: INSTRUMENTATION & CONTROL SYSTEMS

Academic year: 2017-2018 Branch: Mechanical Engineering Year& sem: III&I

Course Objectives: The course focuses on imparting the principles of measurement which includes the working mechanism of various sensors and devices that are in use to measure the important physical variables of various mechatronic systems.

Lesson Plan

Lecture Title of the topic Remarks Number UNIT-I 1 Definition – Basic principles of measurement, measurement systems, Generalized configuration and functional descriptions of measuring instruments, 2 Examples of measurement systems, Dynamic performance characteristics 3 Sources of error, classification and elimination of error 4 TUTORIAL-1 5 MEASUREMENT OF DISPLACEMENT: Theory and construction of various transducers to measure displacement 6 Piezo electric, inductive, Resistance transducers, Capacitance * transducers 7 Ionization and photo electric transducers, Calibration Procedures 8 TUTORIAL-2 UNIT-II 9 MEASUREMENT OF TEMPERATURE: Classification, * ranges, various principles of measurement 10 Expansion, Electrical resistance, thermistor 11 Pyrometers, temperature indicators 12 TUTORIAL-3 13 MEASUREMENT OF PRRESURE: Units, classification, * different principles used. 14 Manometers, piston, bourdon pressure gauge, Bellows, diaphragm gauge. 15 Low pressure measurements, Ionization pressure gauge, McLeod pressure gauge 16 TUTORIAL-4 UNIT-III 17 MEASUREMENT OF LEVEL: Direct and indirect methods, Capacitive, Ultrasonic level indicator 18 Magnetic ,cryogenic fuel level indicator, Bubbler level indicator 19 FLOW MEASUREMENT: Rota meter, magnetic, ultrasonic, turbine flow meter 20 TUTORIAL-5 21 Hot – wire anemometer, Laser Doppler Anemometer (LDA) 22 MEASUREMENT OF SPEED: Mechanical tachometers , electrical tachometers, Stroboscope, noncontact type of tachometer 23 MEASUREMENT OF ACCELERATION AND VIBRATION: Different simple instruments, Principles of seismic instruments 24 Vibrometer and accelerometer using principle. 25 TUTORIAL-6 UNIT-IV 26 STREES AND STAIN MEASUREMENT: Various types of stress and strain measurements, Electrical strain gauge – gauge factor 27 TUTORIAL-7 Method of usage of resistance strain gauge for bending 28 compressive, 29 Method of usage of resistance strain gauge for bending tensile strains 30 Strain gauge usage for measuring torque, strain gauge rosettes 31 TUTORIAL -8 UNIT-V 32 MEASUREMENT OF HUMIDITY: Moisture content of gases. * Sling psychrometer 33 Absorption psychrometer, Dew point meter 34 MEASUREMENT OF FORCE, TORQUE AND POWER: Elastic force meters, load cells 35 TUTORIAL-9 36 Torsion meters, 37 Dynamometers * 38 TUTORIAL-10 UNIT-VI 39 ELEMENTS OF CONTROL SYSTEMS: Introduction, * importance, Classification – open and closed systems 40 Servomechanisms–examples, 41 TUTORIAL-11 42 Block diagrams, Temperature control system 43 Speed control system, Position control system 44 TUTORIAL-12 REFERENCES: 1. Measurement Systems: Applications & design D.S Kumar. 2. Mechanical and Industrial Measurements R.K. Jain/ Khanna Publishers. 3. Mechanical Measurements BeckWith, Marangoni,Linehard, PHI / PE 4. Instrumentation, measurement & analysis B.C.Nakra & K.K.Choudhary, TMH.