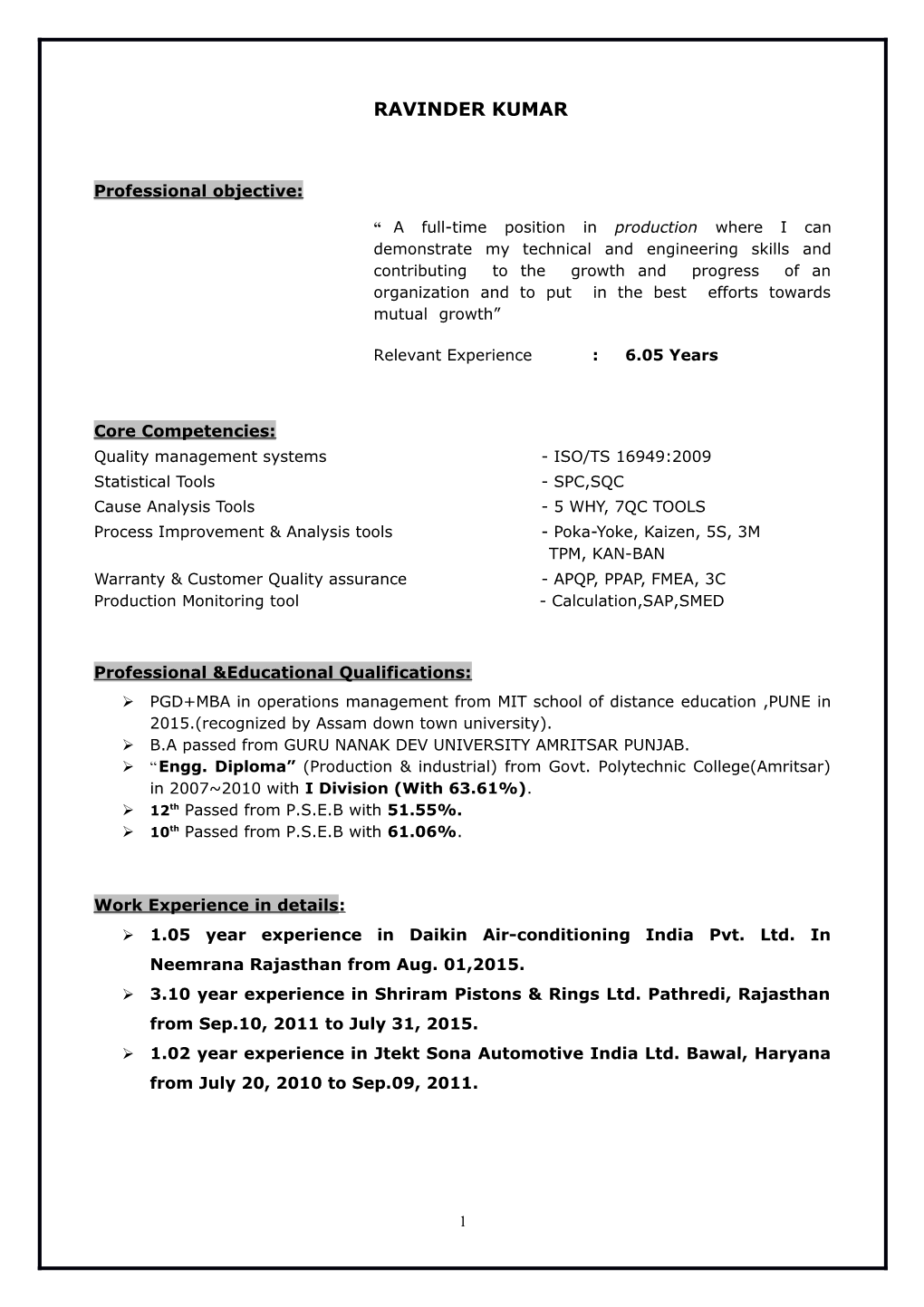

RAVINDER KUMAR

Professional objective:

“ A full-time position in production where I can demonstrate my technical and engineering skills and contributing to the growth and progress of an organization and to put in the best efforts towards mutual growth”

Relevant Experience : 6.05 Years

Core Competencies: Quality management systems - ISO/TS 16949:2009 Statistical Tools - SPC,SQC Cause Analysis Tools - 5 WHY, 7QC TOOLS Process Improvement & Analysis tools - Poka-Yoke, Kaizen, 5S, 3M TPM, KAN-BAN Warranty & Customer Quality assurance - APQP, PPAP, FMEA, 3C Production Monitoring tool - Calculation,SAP,SMED

Professional &Educational Qualifications: PGD+MBA in operations management from MIT school of distance education ,PUNE in 2015.(recognized by Assam down town university). B.A passed from GURU NANAK DEV UNIVERSITY AMRITSAR PUNJAB. “Engg. Diploma” (Production & industrial) from Govt. Polytechnic College(Amritsar) in 2007~2010 with I Division (With 63.61%). 12th Passed from P.S.E.B with 51.55%. 10th Passed from P.S.E.B with 61.06%.

Work Experience in details : 1.05 year experience in Daikin Air-conditioning India Pvt. Ltd. In Neemrana Rajasthan from Aug. 01,2015. 3.10 year experience in Shriram Pistons & Rings Ltd. Pathredi, Rajasthan from Sep.10, 2011 to July 31, 2015. 1.02 year experience in Jtekt Sona Automotive India Ltd. Bawal, Haryana from July 20, 2010 to Sep.09, 2011.

1 Key Skills: Experience in the areas of TPM, Root-cause analyses, SPC, 5-S, ,KAN-BAN, POKA- YOKE, KAIZEN, JIT, 7QC tools, Lean Mfg. OHSAS18001:2007, ISO 9001:2000,ISO14001,TS 16949. Excellent negotiation skills/ Good upward and downward communication skills. Rejection & Rework control by SPC & 7QC TOOLS Techniques. Participate to resolve customer compliant by Kaizen. Productivity improvement through effective line balancing Devoted to hard work and Eveready to take up major responsibilities. Ability to follow systems and procedures, which are implemented for good results. Good exposure and troubleshooting knowledge in Brass, Aluminium, Cast Iron alloy metal machining, different control of CNC Fanuc, Mazak, Simens. Good Knowledge about CNC Machines Like as ACE MICROMATIC,TAURAS & TAKISAWA(JAPAN) MACHINE. Ability to develop the techniques to Cost reduction, Improve quality& work simplification. Knowledge of CNC programming, G code & M code, FANUC, MAZAK & SIMENS Control system of CNC, TURNING TOOLS & INSERTS

Computer Skills Operating system : Window (XP, Win 7,Win 8) Application Software : M.S. Office 2007, SAP,ALPHA CNC PROGRAMMING : FANUC, MAZAK, SIMENS

Achievements: Reduced in-house direct rejection by various kaizen & improvement. 3.6 Lacks/annum material cost saving in Bajaj model. PRDUCTIVITY IMPROVEMENT 98% to 108% By elimination muda and by reducing 2 manpower. Improvement in process to reduce operator's fatigue.

Employment Narration:

Current Employer M/S DAIKIN AIRCONDITIONING INDIA PVT.LTD.NEEMRANA Designation ENGINEER- Production Duration AUG.01-2015 –Till Date DAIKIN AIRCONDITIONING INDIA PVT.LTD.NEEMRANA is a Unit Of Manufacturer of world’s no.1 Eco-friendly air-conditions for domestic and commercial uses. Daikin is a japaness based MNC and company have the following business units Room Air-condition, VRV & chillers. The $14 Billion Daikin industries are a multi-product company with the air conditioning business comprising 87% of its business, It has the 10% of the share in the residential air-conditioning market and 36% in the commercial air-conditioning in Japan. In India, the company has the market share of more than 50% in its respective segment. Daikin is the only air-conditioning company worldwide which manufactures everything on its own from refrigerants to compressors.

Previous Employer M/S SHRIRAM PISTONS& RINGS LTD.PATHREDI Designation SHIFT ENGINEER- Production

2 Duration SEP.10,2011 – JUL.31,2015 Today, SPRL is India’s largest integrated manufacturer of Pistons, Piston Rings, Gudgeon Pins and Engine Valves. The Company’s products are marketed under the brand names USHA and SPR. “Total Customer Satisfaction through Quality Management” has seen us grow from strength to strength. The company has also received the best vendor award from most OEMs.

"Trading House" status from Government of India. and are also amongst the best recognized brand.

Previous Employer M/S JTEKT SONA AUTOMOTIVE INDIA LTD.BAWAL Designation JUNIOR ENGINEER- PRODUCTION Duration May, 2010 –June, 2012 JTEKT SONA AUTOMOTIVE INDIA LTD. is a japness based MNC and it is TS 16949, ISO:14001 Certified Company and the manufacture of Column type electric power steering in partnership with Sona Koyo Steering Systems Ltd. (SKSS). JTEKT owns 51% of the joint venture, and SKSS owns 49%.Main customer of company is Maruti Suzuki Automotive India Ltd, Nissan, Toyota, Honda & Renault Nissan etc.

Roles & Responsibility:

SHEET METAL LINE: - Role as a Line controller & currently working in greenhouse project Neemrana Plant Rajasthan. Shop floor Supervision & manpower handling. Running shifts independently with 25+ man power. To maintain 5 ’S’ activities on shop floor. Internal activities in section for Kaizen awareness. Achievement of daily & monthly based target. Prepared the multiskilling chart and training plan of associates. Rejection control and resolve daily production problem. Managing interface within the company with other departments. Handling WELD SHOP( MIG,SPOT & projection welding), SHEET METAL, Handling sub-Assembly, Improvement Projects Capabilities. Ensure discipline at shop floor, quality ,House Keeping and 5-S concept. Knowledge of best practices like , Kaizen, 5-S, Poka-Yoke, JIT and Kanban. Focused approach toward continual improvement in terms of Productivity, Quality, cost and delivery by plan action and periodic review. Control of shift production as per plan & deputing Manpower for optimum utilization. All responsibility for Quality, Production & delivery on daily basis. Responsible for preparing production planning as per FIFO & JIT system. Good Knowledge of AMADA Control system of NCT punching and Press brake (bending) machine. Good Knowledge of CNC, SPM, PLC machines and control system. Responsible for preparing scrap report. Implementing KAIZEN and POKA-YOKA for easy working and reduce cost, Accident & Problems. Daily production planning, Daily Review of Production and Rejection, Co- ordination with internal customer regarding production planning, material inventory, material handling. PDS (Production Daikin System) of All units with the team. (A. Grasp the current situation B. Graph the current situation discover problem, C. Select theme D. Set a kaizen target E. Create kaizen schedule F. Gather the information on problematic point G. Proper kaizen ideas .H. Implement kaizen ideas I .From

3 verification to confirmation of effects J. Countermeasure K. Re-kaizen L. Summery M. Presentation.) Ensure timely Preparation & up-gradation of all the documents. Production controlling of VRV (Variable Refrigerant Volume) Unit on Main line as well as Sub shops and chillers. Documents controlling of shop-floor .(GWS.CHECK POINT,MQ,DAILY CHECK SHEET,ONE POINT TEXT,ACTION PLAN,PRODUCTION CONTROLL CHECK SHEET) . Controlling Monthly Kaizen reporting for active the BENCH MARK and Productivity. Knowledge of fabrication of sheet metal parts on shop floor. Process modification & improvements to increase the productivity. Streamlining existing systems for achieving enhanced operational efficiency. Monthly Inventory controlling in shop-floor material. Continuously improvement in process & balancing line to increase the quality & productivity. Line Balancing and optimizing man & machine utilization to achieve preset targets by identifying & upgrading various tools & equipment’s required for productions. Yearly plan for the retraining of special process & technical training (Brazing & mig- welding). Time study and line balancing. Formulating pre-planned developmental strategies for achievement of goals and targets.

Audit plan controlling : -- Why-why analysis -- Monthly defect countermeasure -- Action plan Progress -- B-KANSA Defect -- Quality Circle status -- PDS status

Controlling the Training plan all line employees. -- Brazing training -- Safety training -- Crane training -- Lifter training -- 4RKY Training -- OJT Planning

Personal Profile

Father’s Name : Sh.RAM BARAN Mother’s Name : Late Smt.Shanti Devi Marital Status : Single Language known : English, Hindi and Punjabi Passport no. : M2970178 Driving licence no. : PB-0220140165540 Current CTC : 4.50 lac/ annum Salary Expected : Negotiable Notice Period : 2 Month Correspondence address : H.No.3,Preet vihar, ganpat nagar Dharuhera chungi, Rewari-Haryana

Declaration & Beliefs I hereby declare that the above-mentioned information is correct up to my knowledge and I bear the responsibility for the correctness of the above-mentioned particulars.

4 Place: REWARI Date: 14-JAN-2017 Ravinder Kumar

5