Li and Ca ION BEAMS PRODUCTION

A.EFREMOV, S.L.BOGOMOLOV, V.B.KUTNER, A.N.LEBEDEV, V.N.LOGINOV, N.Yu.YAZVITSKY

FLNR, Joint Institute for Nuclear Research, Dubna, Moscow reg.,141980 Russia

Abstract During the last year our design efforts have been focused on the production of 7Li2+ and 48Ca6+ ion beams from ECR ion sources DECRIS-14-2 and ECR-4M respectively. In both cases the required beam intensities should exceed 100 eA. For that purpose the new microoven for the evaporation of metal samples has been designed. Relatively high ion currents required in case of Li and Ca beams have risen the problem of the working material consumption. To reduce this problem the thin cylindrical tantalum sheet thermally insulated from the water cooled chamber wall was installed inside the ionisation chamber. During the source operation the sheet was heated by the plasma electrons and the microwaves. In a long-term operation with the ion currents in the range of 100 200 eA the Li and Ca consumption was less than 0.7 mg/h. The ion beam was stable and only a small addition of support gas was required.

1 Introduction 140 During the past few years the performance of the 1+ cyclotrons in the FLNR JINR was upgraded to a great He Ca6+ extent. Two axial injection systems for the U-400M and U- 120 400 cyclotrons were constructed and put into operation in 7+ Ca 5+ the beginning of 1995 and in the second half of 1996, 100 Ca respectively. The first one uses the ECR ion source DECRIS-14-2, which was designed and built in Dubna [1].

] 80

The axial injection system for the U-400 cyclotron operates A 4+

8+ Ca with the ion source ECR-4M, supplied by GANIL [2]. e [ 2+ Ca

According to the scientific program of the FLNR I 60 He JINR two ion beams were the most important for physical 7 2+ experiments in 1997 and 1998. The first one is the Li 40 beam from DECRIS-14-2 + U-400M cyclotron for 6He secondary beam production to be used in the experiments on the High Resolution Channel of Radioactive Beams. The 20 second one is 48Ca6+ beam from ECR-4M + U-400 cyclotron for the superheavy elements program. For both cases beam 0 intensities of more than 100 eA and long term stability are 40 60 80 100 120 140 required. Imag [A]

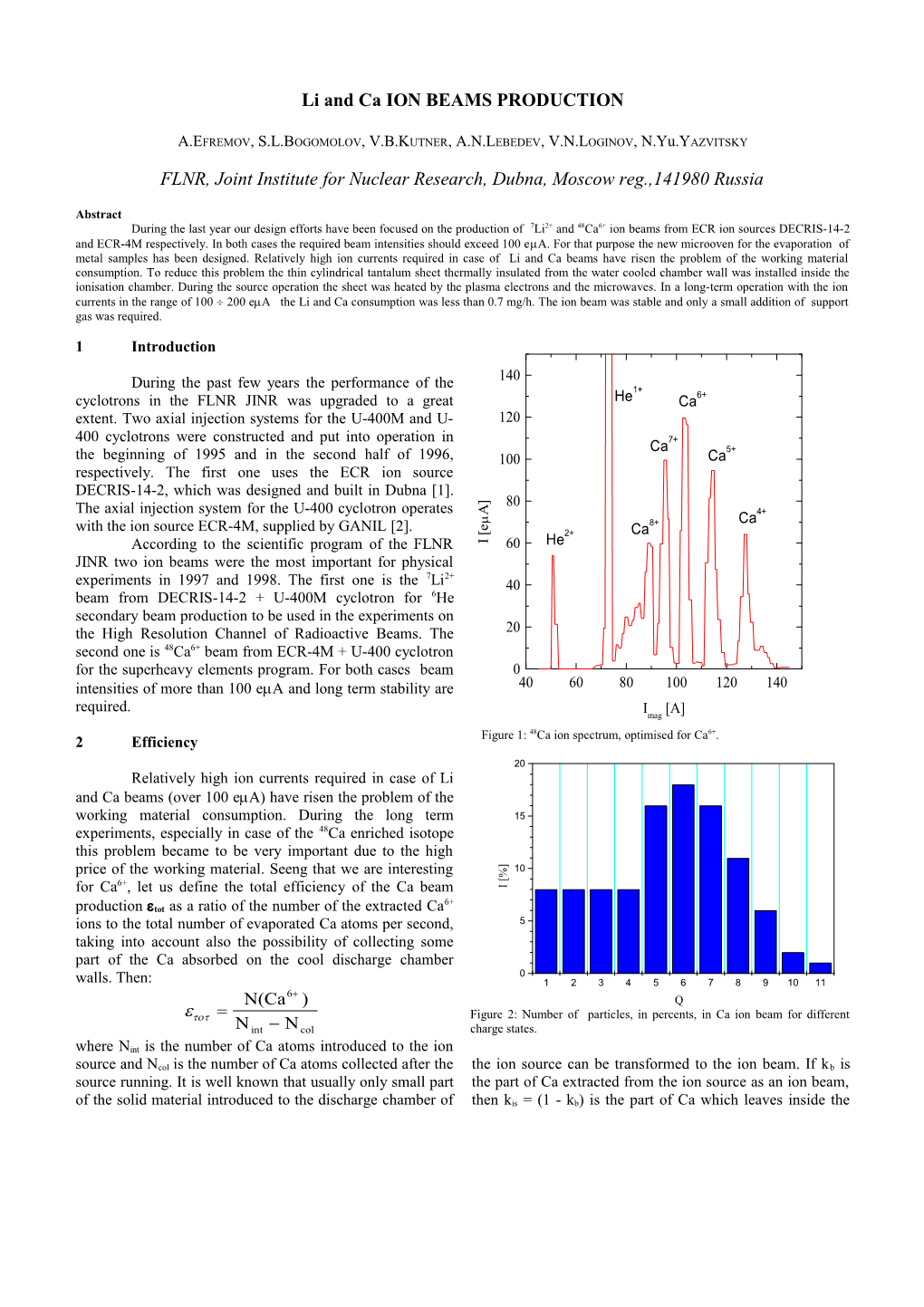

48 6+ 2 Efficiency Figure 1: Ca ion spectrum, optimised for Ca . 20 Relatively high ion currents required in case of Li and Ca beams (over 100 eA) have risen the problem of the working material consumption. During the long term 15 experiments, especially in case of the 48Ca enriched isotope this problem became to be very important due to the high price of the working material. Seeng that we are interesting ] 10 % [ 6+ for Ca , let us define the total efficiency of the Ca beam I 6+ production tot as a ratio of the number of the extracted Ca ions to the total number of evaporated Ca atoms per second, 5 taking into account also the possibility of collecting some part of the Ca absorbed on the cool discharge chamber 0 walls. Then: 1 2 3 4 5 6 7 8 9 10 11 6 N(Ca ) Q Figure 2: Number of particles, in percents, in Ca ion beam for different N int N col charge states. where Nint is the number of Ca atoms introduced to the ion source and Ncol is the number of Ca atoms collected after the the ion source can be transformed to the ion beam. If kb is source running. It is well known that usually only small part the part of Ca extracted from the ion source as an ion beam, of the solid material introduced to the discharge chamber of then kis = (1 - kb) is the part of Ca which leaves inside the ion source. So the equation for tot can be written as:

k b tot 1 k is col reg

where col and reg are the collection efficiency and the regeneration efficiency of Ca, is the part of Ca6+ ions in the Ca ion beam. The typical spectrum of 48Ca ion beam extracted Figure 4: Microoven. 1,2 - body, 3 - electrical connector, 4,5 - ceramic from ECR-4M during the routine operation is presented in insulators, 6 - heater. Fig. 1. Figure 2 shows the number of particles, in percents, 48 in Ca ion beam for different charge states. Here we about 9000C. For this reason stainless steel was chosen for assumed that for lowest charge states, such as Ca1+, Ca2+ and 3+ 4+ the oven elements manufacturing. The absence of expensive Ca the number of particles are the same as for Ca . Taking alumina insulators makes this oven very cheap. A stainless into account that in our case = 0.18 it is possible to steel crucible with solid samples may be placed directly 6+ calculate the total efficiency of Ca ion beam production for inside the heater. A metal vapor feed may be sensitively different values of kb and col reg. As it shown in Fig. 3 the controlled by the heating current. Since the wire of the total efficiency depends dramatically on the percentage of heater is protected by the screen, the lifetime of the oven the evaporated Ca atoms transformed into the ion beam. For seems to be long anough. By now the oven has worked for about 1300 hours without any damages. 0,20 Since only a small fraction of the evaporated metal really goes into the beam the rest are condensed at the water 0.9 cooled chamber walls. One possible way to change this 0,15 balance is to use a hot screen with temperature high enough to evaporate a metal atoms condensed on it. This screen should not influence the correct functioning of the ion

t 0,10 o t

source. In our case this request is not so critical because the required charge state of Ca ions is not so high. For this 0.5 0,05 purpose we install the thin cylindrical tantalum sheet inside the ionization chamber. The diameter of this screen is few millimeters smaller than the diameter of the discharge 0,00 chamber and it is thermally insulated from the water cooled 0,0 0,2 0,4 0,6 0,8 1,0 chamber wall. During the source operation the screen is

kb heated by the plasma electrons and the microwaves. As a

Figure 3: Total efficiency vs kb for different col reg. result, the more to feed the microwave, the higher the temperature of the screen. Measured and calculated temperature of the screen are shown in Fig. 4. example, for the case where kb = 0.5 the total efficiency will Figure 5: Measured and calculated screen temperature vs microwave be approximately three times higher compared the case T 0C where kb = 0.1. It also clear that the total efficiency depends 600 very much on the efficiency of the collection and regeneration of Ca absorbed on the discharge chamber wall. 500

3 Production of Li and Ca ion beams 400 T Measured Significant progress in metal ion production was 300 made possible owing to the development of a new t Calculated microoven for the evaporation of metal samples. Our design 200 efforts were focused to ensure the reliability and long 100 lifetime of the microoven itself according to the requests of 0 100 200 300 400 500 600 the experiments with the Li and Ca ion beams. The new P (W) oven power. (see Fig. 4) consists of a stainless steel body, ceramic Figure 6: Li ion beam spectrum, optimized for Li2+ (a - without screen, b - insulators and a special heater. The heater itself consists of with screen). NiCr wire with mineral insulation contained in a stainless steel screen. The maximum temperature for the heater is a

This new method for production of ion beams of beam. Some simple calculations gives the value of about metals and compounds with low evaporation temperatures, 30%. According of the numerical simulation which are such as Li, Mg, Ca etc.which include the combination of the shown in Fig. 3 the total ion source efficiency including the microoven with the hot screen was originally tested for Li at collection and regeneration of absorbed on chamber wall Ca

the ECR ion source DECRIS-14-2. 1,0 GANIL According to the measurements, presented in Fig. 5 25 the microwave power in the range from 200 to 300 W is 0,8 20 h

enough to heat the screen for the temperature of more than m/t / 0 g % 0,6 m

15

, 400 C. With this temperature the Li vapor pressure of the , n t i I / -3 / t u o order of 110 mbar can be reached. m I 10 0,4 .These tests showed that the screen does not disturb FLNR 5 the plasma very much. It was possible to produce about 290 0,2 2+ emkA of Li (Fig.3, b) with the microwave power of 300 0 W. The beam was very stable and only a very small addition 0 20 40 60 80 100 I , eA of the He was required. In a long-term operation the Li ECR consumption was less than 0,7 mg/h. As shown in Table 1, will be in the range of 812 %. the yield of Li2+ when the combination of microoven with the hot screen was used is more than five times higher Acknowledgement. This work has been partly funded by comparing to the case without screen. the International association INTAS under Grant 96-0299. It is important to note that in experiments with Li References ion beam production we had never optimized the ion source [1] A.Efremov et al., Rev. Sci. Instr., V 69, N 2, 1998, p.662 to minimize the working material consumption. Nevertheless, according to our estimations in the case with [2] R.Leroy et al., Proc. of the 12th Int. Workshop on ECR the hot screen the part of evaporated Li atoms transformed Ion Sources, RIKEN, 1995, INS-J-182, p.57 to the ion beam was increased up to eproximately 20 % compare to the case without screen where more than 95% of [3] E.Baron et al. Proc. of the 11th Intern. Conf. on atoms were absorbed on the chamber wall. Cyclotrons and their Applications, ed. by M.Sekiguchi, Y.Yano, K.Hatanaka (October 13-17, 1986), Ionics Table 1. Yields (eA) for Li from DECRIS-14-2. Publication Company, Tokyo, Japan 1986, p.234

Q 1+ 2+ 3+ Notice [4] V.B.Kutner et al. This Proceedings b 7Li 15 50 25 no screen 7Li 180 290 50 with screen a In the case of 48Ca the problem of total efficiency, including the ion beam production, the beam transport and acceleration becames to be most important. As it shown in Fig. 1 it was not so difficult to produce the 48Ca6+ ion beam Fig.7 Experimental results for the bunching effect and consumption of metallic 48Ca versus the ion beam intensity from the ion source

with intensity more than 100 A. At the same time it was decided to take into account the efficiency of a buncher versus the ion beam intensity, which has been obtained by the GANIL [3] and FLNR [4] groups. Fig. 7 shows that for the optimal 48Ca consumption the ion beam intensity should be of about 30 40 eA. For this case comparatively low consumption (about of 0.4 mg/h) was reached. It means that introducing of about 1.41015 pps into the discharge chamber we produce about of 2.81014 pps as a total 48Ca beam including about of 61013 pps of 48Ca6+. Taking into account the beam transport efficiency from ECR ion source prior to faradey cup (about of 0.6) it will come to about of 7% of the ion source efficiency for Ca6+ production. It is also possible to estimate the persentage of evaporated Ca atoms which were transformed to the ion