MATERIALS TESTING OCTOBER 2005

UNCONFIRMED MINUTES OCTOBER 17 - 21, 2005 MARRIOTT CITY CENTER PITTSBURGH, PENNSYLVANIA

These minutes are not final until confirmed by the Task Group in writing or by vote at a subsequent meeting. Information herein does not constitute a communication or recommendation from the Task Group and shall not be considered as such by any agency. MONDAY, OCTOBER 17, 2005 – CLOSED SESSION (MORNING)

1.0 OPENING COMMENTS

1.1. Call to Order/Quorum Check

The meeting was called to order by Chairperson Keith Kastner. A quorum of Primes were present for the Closed sessions and a quorum of Primes and suppliers were present for the Open sessions. The meeting minutes from the July meeting were approved.

1.2 Introductions were made by all attendees.

1.3 Attendance

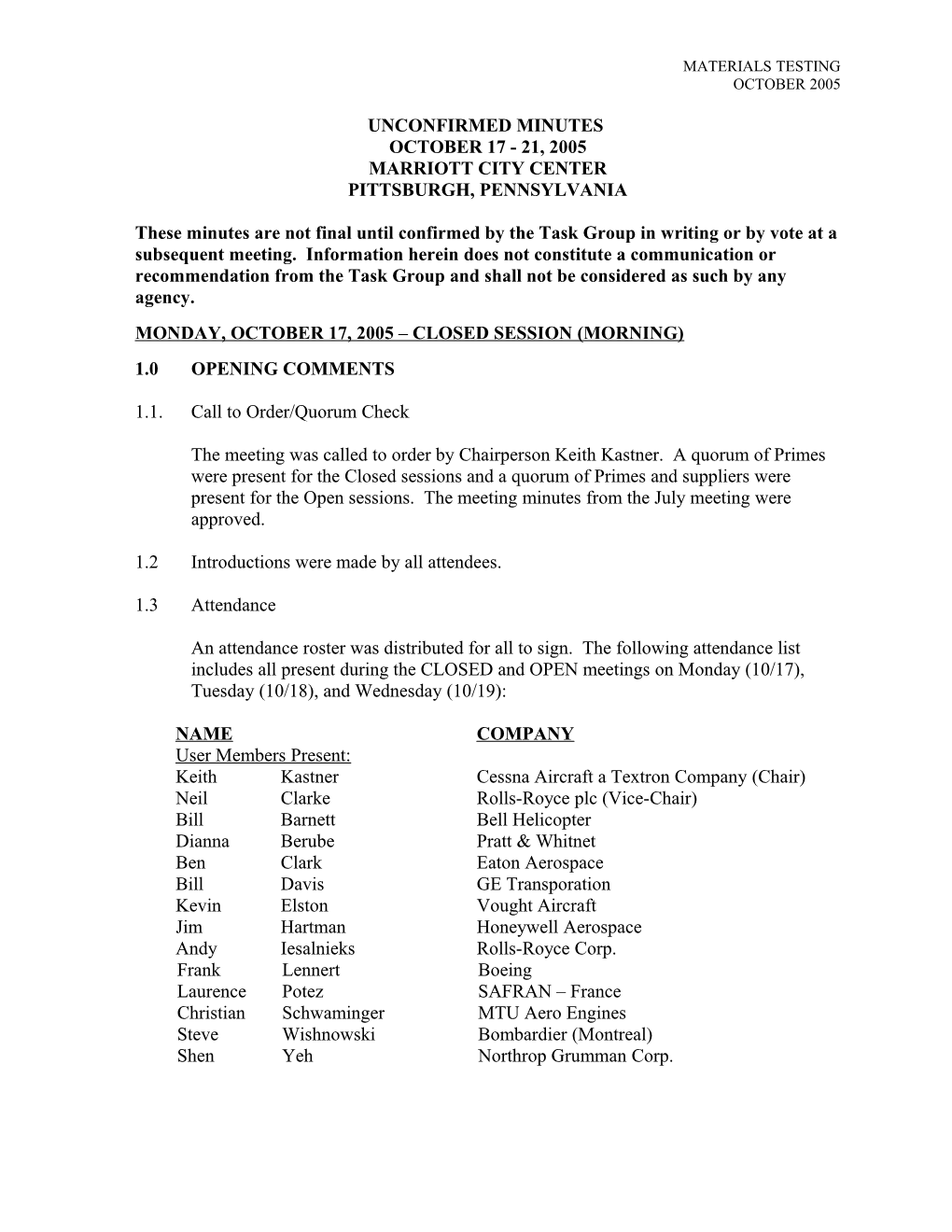

An attendance roster was distributed for all to sign. The following attendance list includes all present during the CLOSED and OPEN meetings on Monday (10/17), Tuesday (10/18), and Wednesday (10/19):

NAME COMPANY User Members Present: Keith Kastner Cessna Aircraft a Textron Company (Chair) Neil Clarke Rolls-Royce plc (Vice-Chair) Bill Barnett Bell Helicopter Dianna Berube Pratt & Whitnet Ben Clark Eaton Aerospace Bill Davis GE Transporation Kevin Elston Vought Aircraft Jim Hartman Honeywell Aerospace Andy Iesalnieks Rolls-Royce Corp. Frank Lennert Boeing Laurence Potez SAFRAN – France Christian Schwaminger MTU Aero Engines Steve Wishnowski Bombardier (Montreal) Shen Yeh Northrop Grumman Corp. MATERIALS TESTING OCTOBER 2005

NAME COMPANY Suppliers Present: Rich Balamut Shiva Technologies Corwyn Berger Bodycote Materials Testing Ken Broenner Metcut Research John Chir Timken Latrobe Steel Joe Chivinsky Nadcap Auditor Tom Cunningham Haynes International Marsha Davis Lockheed Martin Eric Dirats Dirats Laboratories Manna Domenico Alenia Aeronautica Irene France Cambridge Materials Testing Niko Gjaja The M&P Lab Mark Grassi Carpenter Technology Mike Higgins Stork-SMT Jim Kapraly PCC Airfoils Michai Lanton Crestview Aerospace Corp. John Low Timet Toronto (US) Paul McCarthy Nadcap Auditor Annette O’Connell Haynes International Lisa Potoma NSL Analytical Jim Rossi Westmoreland Mechanical Testing & Research Steve Ruoff IMR Test Labs Richard Simmons Dirats Laboratories Byron Skillings Ladich Co. Jeffry Smith Tensile Testing Metallurgical Laboratory Janice Telford QChem Labs

PRI Staff Present David Luoni Materials Testing Senior Staff Engineer Lisa Zajacs Committee Service Representative 1.2 Approval of Previous Meeting Minutes The minutes from the July 2005 meeting were approved. 2.0 RULES OF CONDUCT The Staff Engineer reviewed the rules of conduct for the Nadcap meetings. 3.0 SUPPLIER PRESENTATION A presentation was made by a supplier regarding the 25 mile rule for satellite facilities and outbuildings, indicating that he would like to see the distance between facilities extended. Also, feedback was provided to the Task Group on recent audits, since June 1998. A number of points were included, including scheduling concerns.

Page 2 of 10 MATERIALS TESTING OCTOBER 2005

ACTION ITEM: Staff Engineer to contact NACLA regarding their requirements specific to satellite facilities, and to review ISO/IEC 17011 to identify any policies regarding satellite facilities that may impact PRI’s satellite policy. The Staff Engineer will provide this information in the regularly scheduled Task Group conference call in November.

The supplier was asked back for further discussion and ideas for solutions.

4.0 PRIME TUTORIAL MINI-ORIENTATION

An overview of the program was presented for new Task Group members by the Staff Engineer.

The Task Group set up a mentoring situation for newer members. The members and their mentors are as follows:

Bill Davis / Neil Clarke Marsha Davis / Frank Lennert

5.0 PROGRAM STATUS

Two slides providing an overview of the program was presented by the Staff Engineer. This presentation was also made during the open meeting on Monday afternoon.

6.0 NEW AUDIT FREQUENCY LETTER

The letter was reviewed and finalized. A note will be added to specify that Nadcap will make every effort to balance the audit length for each surveillance audit. The letter was also presented during the open meeting on Monday afternoon.

MONDAY, OCTOBER 17, 2005 – AFTERNOON SESSION (OPEN)

7.0 REVIEW & RESOLUTION OF AC7101/3 BALLOT

A working group was established to simplify the Mechanical Testing Matrix (AC7101/3, Figure 1) - Joe Chivinsky, Paul McCarthy, Jim Hartman.

MOTION : Set up individual check boxes plus add a note: “laboratories shall have one or both of the applicable specifications”. Motion Approved.

MOTION: Add parenthesis with (PR EN 2002-1, PR EN2002-2). Motion Approved.

MOTION: Section 9.8, 9.9: Make alignment a separate section (section 10). The LCF alignment requirements.would also be moved. Motion Approved.

Page 3 of 10 MATERIALS TESTING OCTOBER 2005

MOTION : Section 10.7: Accept Jim’s revised wording (documented on the ballot comments form (Excel). Motion Approved.

It was decided to defer discussion of section 11.1.1 until Tuesday PM.

MOTION: Section 11.3: Move Cyclic Rupture from Creep section to fatigue section. The motion was withdrawn by J. Hartman.

MOTION: Section 11.3.6: Add the words that were added to the ballot comments form. Motion Approved.

ADJOURNMENT

TUESDAY, OCTOBER 18, 2005 – OPEN SESSION

8.0 CURRENT ROCKWELL HARDNESS TESTING REQUIREMENTS

A formal program by Bob Ellis of the David Ellis Company was presented. 1. ASTM E18-05 was released this spring, but is now obsolete by the issuance of ASTM E18- 05e1. Discussion of the changes ensued. 2. Use of the Carbide Ball - It has been proven that the performance is better and more consistent, but a slight shift of minus 0.4-0.6 HRB by NIST. Some claim more shift, but that can not be documented. In any case, the Nadcap checklist (AC7101/5) must be revised to reflect the Carbide Ball requirement. Dual calibrations are needed if both Steel Ball and Carbide Ball are used.

Switch to Carbide Ball – still about 20% not using carbide ball. ASTM is currently adding uncertainties for each hardness testing procedure E10, E18, E92. The most recent version of ASTM E384-05 has been out for 4 weeks.

9.0 MEETING WITH HEAT TREATING SUBTEAM: HARDNESS TESTING

Mitch Nelson (Cessna), Vice Chair of the Heat Treating Task Group, made a short presentation to the MTL TG, regarding the HTTG’s history and identified seven 7 issues that need to be resolved.

The need to streamline AC7101/5 was discussed. It was noted that there is a lot of data collection in the document, but the need for this data was questioned.

A mutual agreement was struck, with the purpose to improve AC7101/5 to be useful for both Task Groups.

Page 4 of 10 MATERIALS TESTING OCTOBER 2005

ACTION ITEM: Establish a joint subteam with the HTTG subteam to review and evaluate AC7101/5, and also to review AC7101/1 to see if there is specific information from that document that should be included in AC7101/5 to enable it to be a more stand-alone checklist. The team must establish a charter during the first meeting (teleconference).

Keith Kastner – Prime Mark Grassi - Carpenter Frank Lennert – Prime Paul McCarthy – UK Auditor Laurence Potez (Prime) – will ask SNECMA HT Rep to participate.

ACTION ITEM: Primes are to review the information only sections related to AC7101 /5 and provide feedback to subteam

ACTION ITEM: HTTG to provide comments to MTL Staff Engineer regarding checklists AC7101/3 and AC7101/4 for future discussions.

An AC7101/9 (Heat Treating of Specimens) subteam was formed to liase with Doug Mattson regarding the recent revision to AMS 2750 (Rev. D), and how it may affect the Materials Testing requirements.

Subteam - Eric Dirats, Byron Skillings, and John Low.

7.0 REVIEW & RESOLUTION OF AC7101/3 BALLOT (continued from Monday, October 17, 2005 Agenda Item 7)

MOTION: Section 12.1.3 – reword as follows: Testing speeds for both Room Temperature and Elevated Temperature Tensile tests are a controlled strain rate of 0.003 to 0.007 per minute through yield, with a controlled crosshead speed of 0.04 to 0.06 per minute times the starting nominal gage length until rupture. Motion approved.

MOTION: Add this clause at the beginning of the section: “unless otherwise specified”. Motion approved.

Section 9.9 – Revisited

MOTION: Section 9.9 – Revise the wording as follows: Alignment verification for uniaxial testing is in accordance with ASTM E1012, using the strain gage method for all test standards (International and ASTM). Motion approved.

Section 12.2.3 – Removed “Pacer/”

Page 5 of 10 MATERIALS TESTING OCTOBER 2005

MOTION: Section 12.2.4 – to find the comment nonpersuasive. Motion approved.

ACTION ITEM: Staff Engineer to renumber current sections 13.6.2 – 13.7.

MOTION: Remove sections 14.2.1 and 14.2.2. Motion approved.

ACTION ITEM: Staff Engineer to move sections14.2.18, 14.2.19, 14.3.2 to section 10.4.

ACTION ITEM: Staff Engineer to add the rounding rewording provided by Carl Barrett to section 11.

ACTION ITEM: Staff Engineer to provide the NCSI report and the Welding checklist regarding welding evaluations to all roster members by November 15.

ACTION ITEM: Staff Engineer to request Jennifer Gallagher to contact Laurence Potez regarding presentations for European suppliers by November 11.

10.0 AS7101 REVISION TEAMS

Teams are being established to review and rewrite each section of the AS7101 standard, to include international standard references and to bring the standard up to date with current standards and specifications. Volunteers at this meeting are:

Section 2 – Ben Clark

Section 4 (Requirement All Laboratories) – Marjan Hager, Bill Davis

Section 5 (Chemical Analysis) – Lisa Potoma, John Low (will check with others within Timet for volunteers).

Section 6 (Mechanical) – Jim Hartman, Neil Clarke, Laurence Potez, John Low (will check with others within Timet for volunteers).

Section 7 (Metallography & Microhardness) – Nick Bulloss, Bill Davis

Section 8 (Hardness) – the members of the hardness testing subteam formed earlier will revise this section.

Section 9 (Corrosion) – no volunteers at this meeting.

Section 10 (Mechanical Test Specimen Preparation) – Jim Hartman, John Low (will check with others within Timet for volunteers).

Section 11 (Differential Thermal Analysis) - no volunteers at this meeting.

Page 6 of 10 MATERIALS TESTING OCTOBER 2005

Section 12 (Heat Treating) - John Low, Byron Skillings, Eric Dirats

APPENDICES A-E – Marjan Hager

11.0 AGENDA FOR JANUARY 2006 MEETING

1. AC7101/3 ballot 2. Reports from each AS7101 subteam 3. Hardness subteam report - /5 joint subteam 4. Laurence Potez - Homogeneity study. 5. Welding Task Group definition checklist – give update 6. Chem. Processing – invite Chair and checklist subteam to explain the CP testing checklist and to discuss its implementation into the MTL requirements. 7. AC7006 revised checklist status 8. Global requirements subteam reports

ACTION ITEM: Conference call to review CP checklist to determine January action. Staff Engineer to provide copies of checklist to Primes and setup conference call; December 15.

ACTION ITEM: Keith Kastner to formally approach NMC to setup policy on how Task Groups are to set up testing requirements. All testing requirements must be coordinated through the Materials Testing Task Group for Nadcap recognition and accreditation.

ACTION ITEM: Staff Engineer to send an all roster email announcing AS7101 subteams, and to request volunteers to participate. Also, a matrix listing all applicable testing specifications/standards (US & International) will be provided to all team members by November 15, 2005

ADJOURNMENT

WEDNESDAY, OCTOBER 19, 2005 – CLOSED SESSION

12.0 eAuditNet – FAILURE BALLOTING

A full review of the process regarding Failure Ballots was provided. Also, it was noted that on audit report reviews, if Prime Reviewers have comments regarding a specific NCR, the Prime should post comments in the “Task Group Discussion” section for that NCR.

Page 7 of 10 MATERIALS TESTING OCTOBER 2005

13.0 ISO/IEC 17025 SCOPE OF ACCREDITATION

The policy in NTGOP-001, Appendix was discussed and clarified. The list of ISO/IEC 17025 testing methods was reviewed, and it was reinforced that PRI is responsible for the review and approval of those testing methods.

MOTION: The Materials Testing Task Group Prime Users acknowledge PRI’s authority to perform ISO/IEC 17025 audits for non-aerospace applications, and that these activities shall not interfere with the Materials Testing Task Group’s activities. Motion approved.

14.0 MATERIALS FOR FUTURE IPT PROGRAMS

The Task Group determined the following materials for future IPT programs:

CHEMISTRY Iron Base High Alloy – M50 Iron Base Low Alloy – 4340 Nickel Base – Waspaloy Cobalt Base – L605 Titanium Base – 6-4-2 Aluminum Base – AA7050 Copper Base – BeCu Magnesium Base – AZ91

MECHANICAL Room Temperature Tensile – Ti 6-4 Annealed Elevated Temperature Tensile – Inco 718 Stress Rupture – Inco 718 Creep – Inco 718 Fracture Toughness – AA7050 Cyclic Rupture – 15-5 Low Cycle Fatigue – Inco 718 High Cycle Fatigue – Ti 6-4 Crack Propagation – AA7050 and Inco 718 (do both materials) Brinell Hardness – AA6061 Rockwell Hardness B Scale – AA7075 T62 Rockwell Hardness C Scale – 4340 Steel Vickers Macro – 9310 Steel

ACTION ITEM: Laurence Potez to provide Centech PTP information to Staff Engineer for distribution to all Primes.

Page 8 of 10 MATERIALS TESTING OCTOBER 2005

15.0 LCF/HCF RESOLUTION

The Task Group consensus was that Christian Schwaminger’s explanation was the most succinct.

3.0 SUPPLIER PRESENTATION (continued from Monday AM)

ACTION ITEM: Primes to draft a letter to address the supplier’s letter.

ACTION ITEM: Staff Engineer shall check how many audits were conducted at the supplier’s sites and the length of audit process (cycle time); were any extensions required, etc.

Recommendation: Hold a conference call by November 9 to review the audit. Andy Iesalnieks will draft a response letter and will provide it to Staff Engineer. Task Group members (Andy/Bill) will check with the GE observer on the audit for comments. Staff Engineer to provide the Primes with the PRI Observer’s report. The Staff Engineer stressed that PRI received no formal feedback from the Prime Observer regarding the audit, thus indicating that the Prime Observer had no issues or concerns regarding the audit.

16.0 CHEMICAL PROCESSING CHECKLIST UPDATE

Discussion centered around the CP testing document.

ACTION ITEM: Staff Engineer to provide the Task Group Primes with the CP checklist and setup a conference call with CP Chair, and to arrange a face to face meeting at the January 2006 meeting.

17.0 RECONFIRMATION OF OFFICERS

MOTION: to reconfirm Keith as Chair. Motion approved (unanimous).

MOTION: to reconfirm Neil as Vice Chair – Motion approved (unanimous).

MOTION: to reconfirm Bill Davis as Secretary – Motion approved (unanimous).

18.0 BASELINE CRITERIA

Discussed the questionnaire submitted by the Chair to NMC.

ACTION ITEM: Staff Engineer to send a copy of baseline questionnaire to all Primes by November 15.

Page 9 of 10 MATERIALS TESTING OCTOBER 2005

19.0 ADJOURNMENT

Minutes prepared by Bill Davis ([email protected]) and David Luoni ([email protected]).

***** For PRI Staff use only: ******

Are procedural/form changes required based on changes/actions approved during this meeting? (select one)

YES* NO

*If yes, the following information is required:

Documents requiring Who is responsible: Due date: revision: AC7101/3 David Luoni December 15, 2005

Page 10 of 10